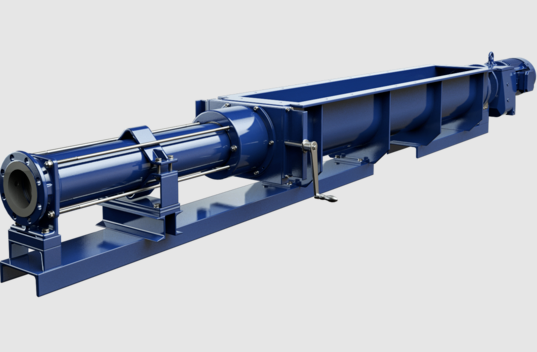

BTES – HOPPER PUMP FOR SILO SYSTEMS

Made for silos: With their long hoppers, BTES hopper pumps from SEEPEX are ideal for installation under a silo. The construction of the rectangular hopper can then be optimally adapted to a wide variety of silo discharge systems. The pumps are ideal for pumping e.g. dewatered sewage sludge to drying or combustion plants. In order to ensure that the silo does not need to be fully emptied before maintenance, the pump is fitted with a closure system behind the hopper – this saves time and money.

Introducing SEEPEX BTES – The Perfect Hopper Pump for Silo Systems

The SEEPEX BTES hopper pump is an ideal solution for conveying and dosing bulk materials in silo systems. With its robust design and high-quality construction, this pump can handle even the most challenging applications with ease. Featuring a hopper that can be customized to fit specific requirements, the SEEPEX BTES can reliably transport various types of dry or wet materials, such as grains, powders, or slurries, without any clogging or bridging. Additionally, this pump offers low pulsation and gentle material handling, ensuring efficient and precise dosing of the transported material. If you are looking for a reliable hopper pump for your silo system, the SEEPEX BTES is definitely worth considering.

Applications of SEEPEX BTES – The Versatile Hopper Pump for Silo Systems

The SEEPEX BTES hopper pump is a versatile solution that can be used in various industries, including agriculture, food and beverage, chemical processing, and wastewater treatment. In the agriculture industry, it can be used to transport grains, feed, and other agricultural products. In the food and beverage industry, it can handle powders, syrups, and other viscous materials. In chemical processing, it can be used to transport abrasive and corrosive chemicals, while in wastewater treatment, it can handle sludge and other difficult-to-pump materials. With its customizable hopper design and high-quality construction, the SEEPEX BTES hopper pump is an excellent choice for any industry that requires reliable and efficient material handling in silo systems.

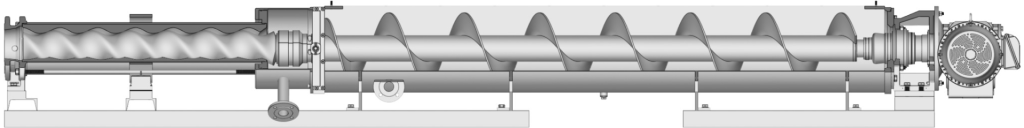

A perfect fit

Structural optimization of the hopper for a perfect fit under the respective silo

No silo emptying

Thanks to integrated closure system in the pump that keeps out non-flowable, semi-solid media, the pump can be maintained wihtout silo emptying

Time-saving

Maintenance time reduced many times over by eliminating the time-consuming silo emptying process

Easy maintenance

Quick and simple maintenance thanks to the easy dismantling of the compression casing

No bridging

Thanks to the shallow design of the hopper

Optimum product conveyance

Conveyance of the optimal flow rate to the downstream rotating unit by compressing the medium in the compression zone

People Also Ask