MXQ MM-Series Pumps

MXQ MM-Series pumps are exact duplicates of the Moyno® 2000 series progressive cavity pumps. These pumps are manufactured to handle thrust and radial loads efficiently. Their high quality gear joints and materials of construction create a very robust, reliable option for your application.

The Description of MXQ MM-Series Pumps

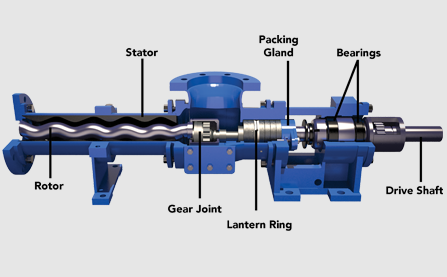

The Moyno MXQ MM-Series progressive cavity pump is built with rugged gear-type universal joints, which is an effective solution to handle heavy radial thrust loads. This design ensures the best perfomance with very minimal maintenance, low wear & tear of rotating parts, and longer life of the pump. These high quality gear joints and materials of construction create a very robust, reliable option for your application. MXQ MM-Series pumps are 100% equivalent to Moyno® 2000 series progressive cavity pumps.

The Featured Benefits of MXQ MM-Series Pumps

- Heavy duty gear joints are used to withstand pressure and

thrust loads. - Stuffing box can accommodate single/double

mechanical seal or packing. - Uses grease packed roller bearings to extend pump life.

- Sturdy castings reduce vibration to shaft and bearings.

- Various materials of construction available.

- Suction chamber can rotate 360° for easier installation.

- Inspection ports for efficient cleaning.

- Non-pulsating flow

- Accurate, repeatable flow

- Head independent of pump speed

- Low NPSH requirement

- Self-priming

- High suction lift up to 28 feet

- Low shear

- No valves to clog or stick

- Reversible

- No timing gear adjustments

- High volumetric and mechanical efficiency

- Smooth fluid discharge

- Ideal for metering application

- Easy to regulate

- Superior abraison resistance

The Applications of MXQ MM-Series Pumps

- Sewage lift stations and headworks

- Primary and tertiary sedimentation

- Grit removal

- Nitrification

- Thickening and conditioning

- De-watering

- Multiphase fluid transfer

- Adhesives

- Slurries

- Chemical metering

- Polymer

- Food and beverage waste

- Starch, slurries, and coatings

- Leaching/ neutralization

- Flocculants

The model number of MXQ MM – Series Pump

| Material | Standard Materials |

| Pump Housing | Cast Iron, Cast Steel, CF8, CF8M |

| Internals (Including Rotor) | Alloy Steel, Tool Steel, AISI 304, AISI 316 |

| Stators | EPDM (to 260ºF) Fluoroelastomer (to 350 ºF) Nitrile (to 210 ºF) Natural Rubber (to 185ºF) |

People Also Ask