Food Grade Pump

Food Grade Pump

The PMV™ C is the shortest stainless steel Progressing Cavity Pump in the market. This new Eco designed and compact pump is dedicated for food markets (FDA and European Food regulations compliant materials).

Its revolutionary design combines the legendary performance and the reliability of PCM Progressing Cavity Pump technology with a highly modular, eco-friendly design. The EcoMoineau™ C pump requires less space for installation which reduces costs and facilitates its integration. Furthermore, this new pump is very easy and quick to dismantle.

Space Saving and Eco-Friendly Design

Space saving

42% shorter – 57% lighter

Its revolutionary design combines the legendary performance and reliability of PCM Progressing Cavity Pump technology with a highly modular, eco-friendly design. The EcoMoineau™ C pump requires less space for installation which reduces costs and facilitates its integration.

Eco Design pump

10% less power consumption

The EcoMoineau™ C pump is lighter (less raw materials) and uses 10% less power than most Progressing Cavity Pump’s on the market.The energy used to manufacture, transport and operate the EcoMoineau™ C pump is therefore optimized.

Easy and quick dismantling

23% maintenance time saving

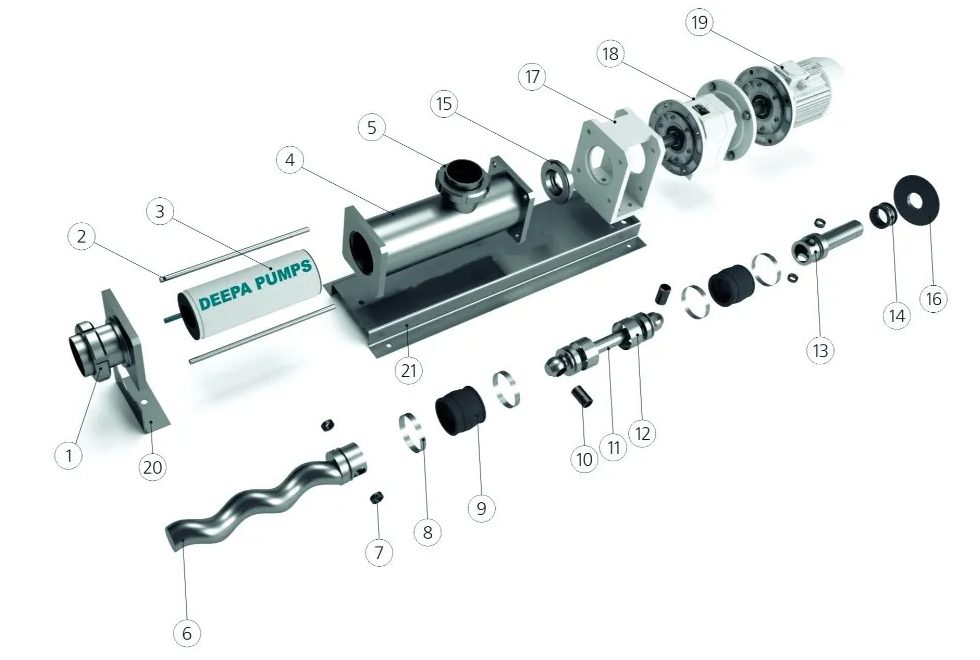

The EcoMoineau™ C pump is made with fewer moyno pump parts compared to competitors models. This new stainless steel pump has a multiple of design features that make installation, operation, and servicing easier than ever before.

Versatile construction

Integrated construction

Cost effective solution including single bellow mechanical seal (self positioning)

Shortest and lightest design

Monobloc and bearing construction

Five sealing solutions available

Spacer xith improved access to the sealing system

Rubber deflector: protecting the drive and bearing therefore.

Food Grade Pump Brewing.

Performance Limits: Flow Rate, Pressure, and Temperature Maximums

Maximum flow rate: from 3 l/h to 180 m3/h /from 0.013 to 792.5 US GPM

Maximum pressure: 16 bar / 232 PSI

Maximum temperature (in continuous operation): 120°C / 248°F

Sugar and starch market: pcm pumps & equipment

Sugar is everywhere, it is an essential ingredient in the manufacturing of multiple recipes. PCM offers solutions throughout the sugar production process, from the transfer of molasses or pulps to the clarification, concentration or crystallization process.

Meat and fish pumps

PCM provides to agri-food industrials custom-designed meat and fish pumps for transferring, mixing and dosing. Click here to learn more.

Beverages: pcm pumps &equipment

There is a common point with all these recipes: liquid product transfer in large quantities generally uses centrifugal pump technology. But when the application becomes more complex, for the transfer of fragile and viscous nectars for example, PCM has the solution.

Convenience food: dosing and filling pcm pumps & equipment

Lifestyles evolution have directly impacted cooking and eating habits, leading to a sharp rise in the ready meals market. PCM responds to this heterogeneity by making on demand systems for dosing viscous, pasty ingredients with or without pieces, for filling all types of containers…

People Also Ask