Netzsch Nm031

Netzsch Nm031

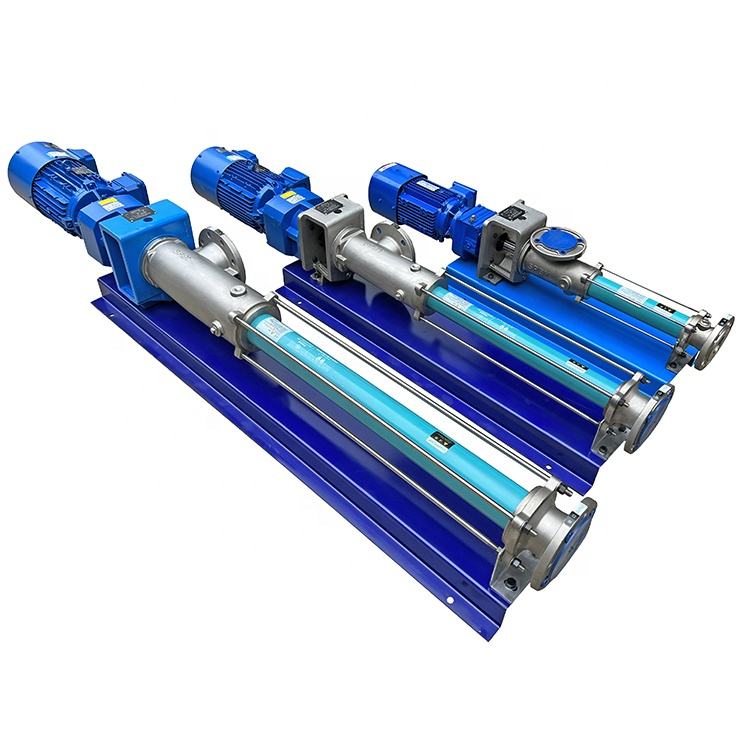

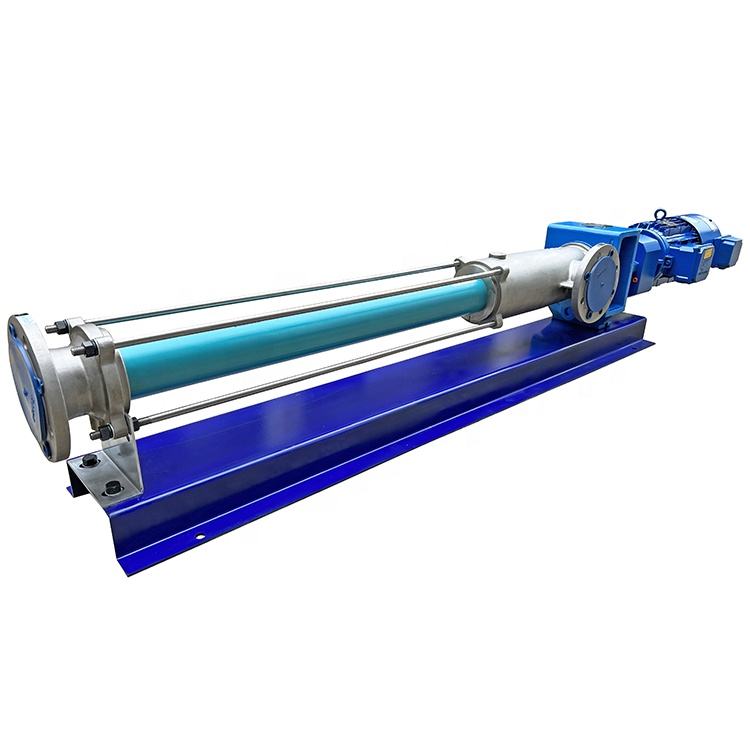

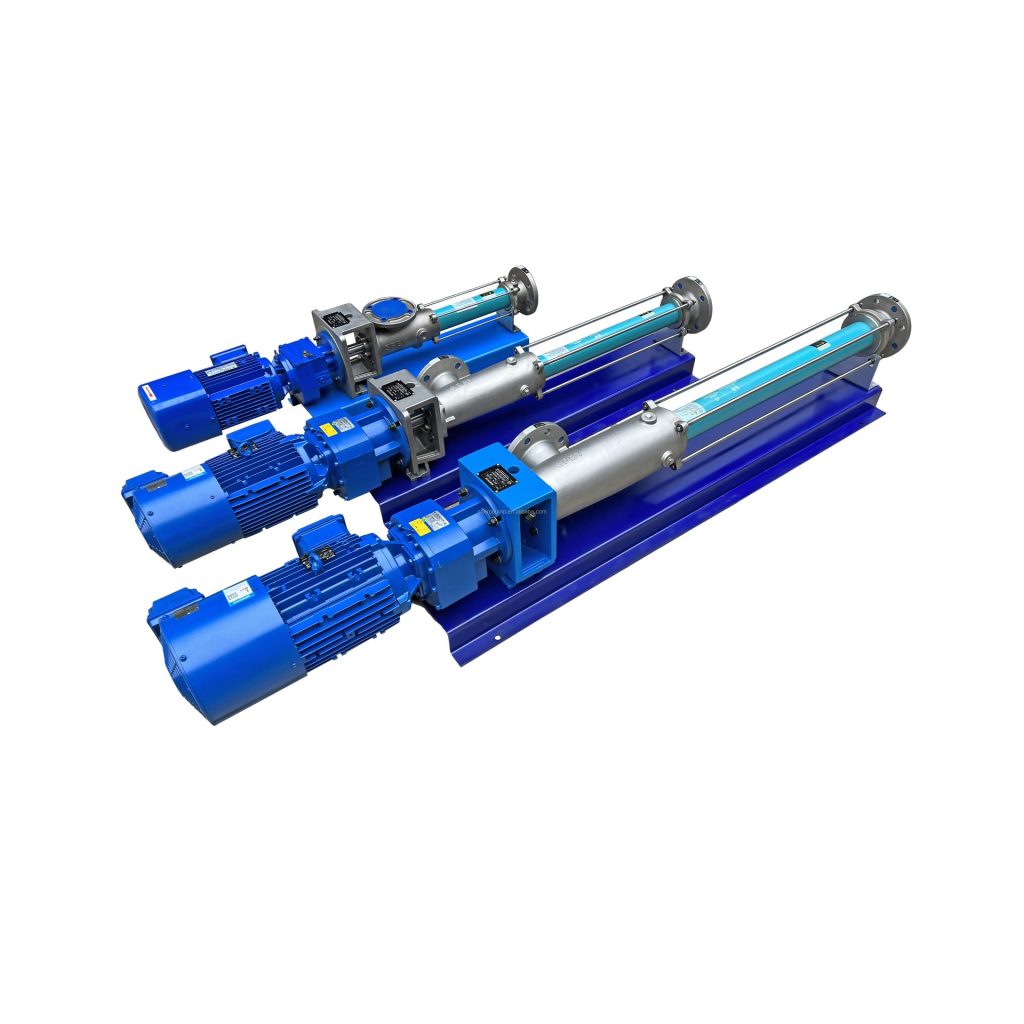

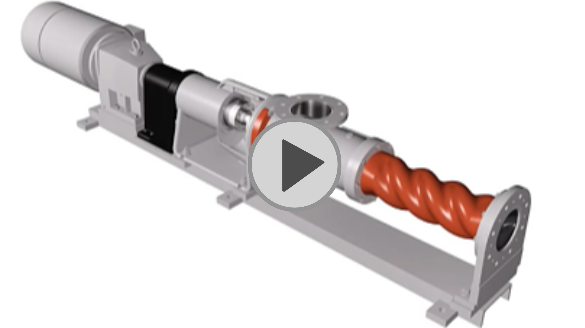

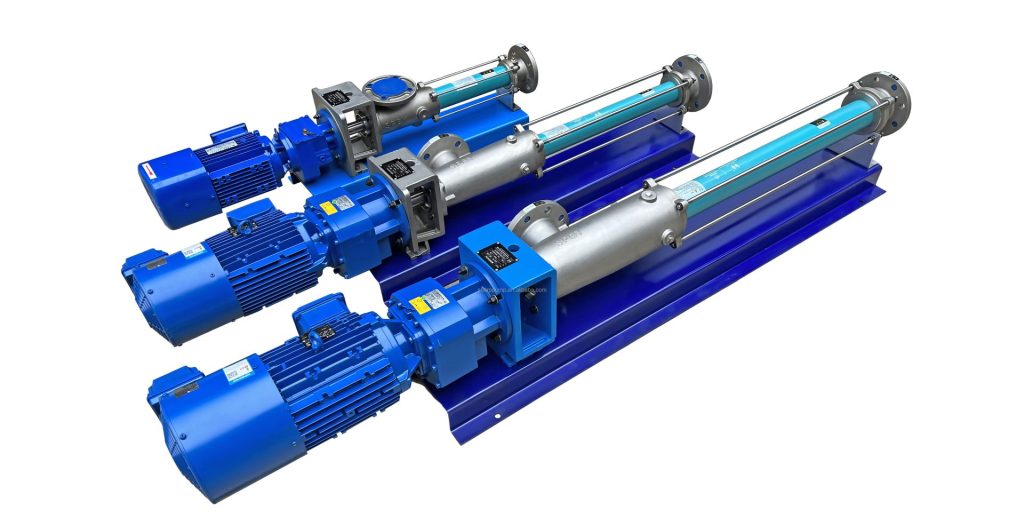

Name:Progressive cavity screw pump

Material :304/316L SS

Certificate:ISO9001-2016

Type:Netzsch type

Applicable industries :Food/Chemical/Paper-making/ Oil/Coal/Shipbuilding/Sewage/ Environmental production/

Metallurgy and mining/:Mine drainage/Construction

The Features of Netzsch Nm031

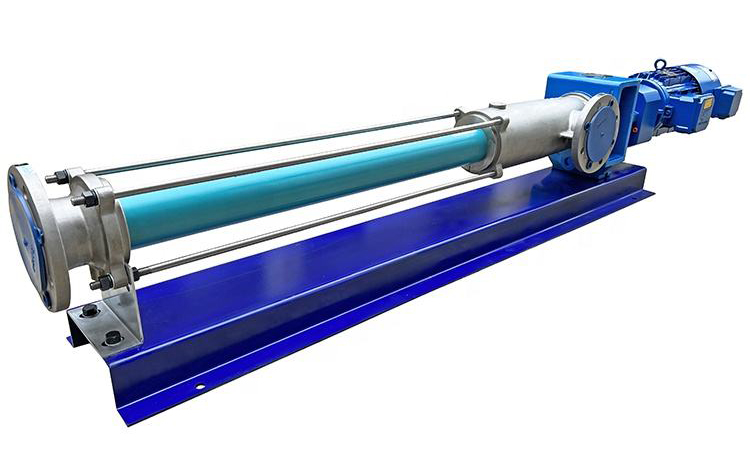

Motor

The motor is SEW gear motor.

Delivery period is about 3 weeks.

netzsch nm031 Pump body

Material of pump body is 304/316L SS.

Strength welded.

Netzsch Nm031 Progressive cavity screw pump Parameter List

| parameter table | OEM | Brand Name: | PMV |

| Model Number: | NM031 | Power Source: | Electric |

| Pressure : | High Pressure | Structure : | SCREW PUMP |

| Usage : | Oil | Application : | Sewage |

| Theory : | Rotary Pump | Material : | Stainless Steel 304 |

| Fuel : | Other |

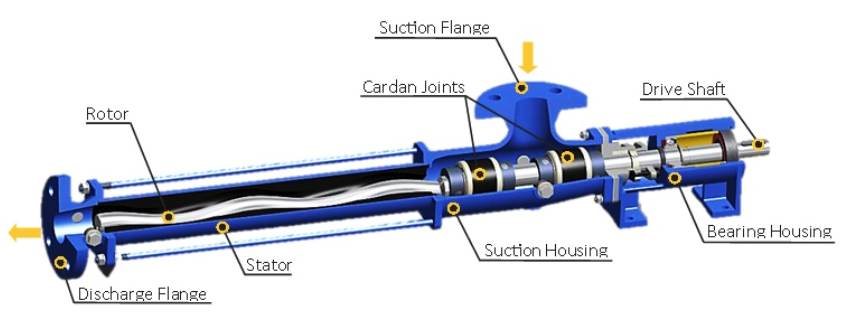

The Netzsch Nm031 Progressive Cavity Pump Parts netzsch pump parts

People Also Ask