Parameters

| Voltage:380V | Flow rate:1.5m³/h | Transport medium:Sewage treatment agent |

| Pump shaft position:Horizontal | Drive mode:Electric | Impeller suction method:Single suction |

| Material:Stainless steel | Scope of application:Sewage treatment | Speed:200RPM |

| Lift:60m | Impeller structure:Single impeller | Pressure:0.5Mpa |

| Model:BN2-6L | Weight:78kg | Brand:Seepex |

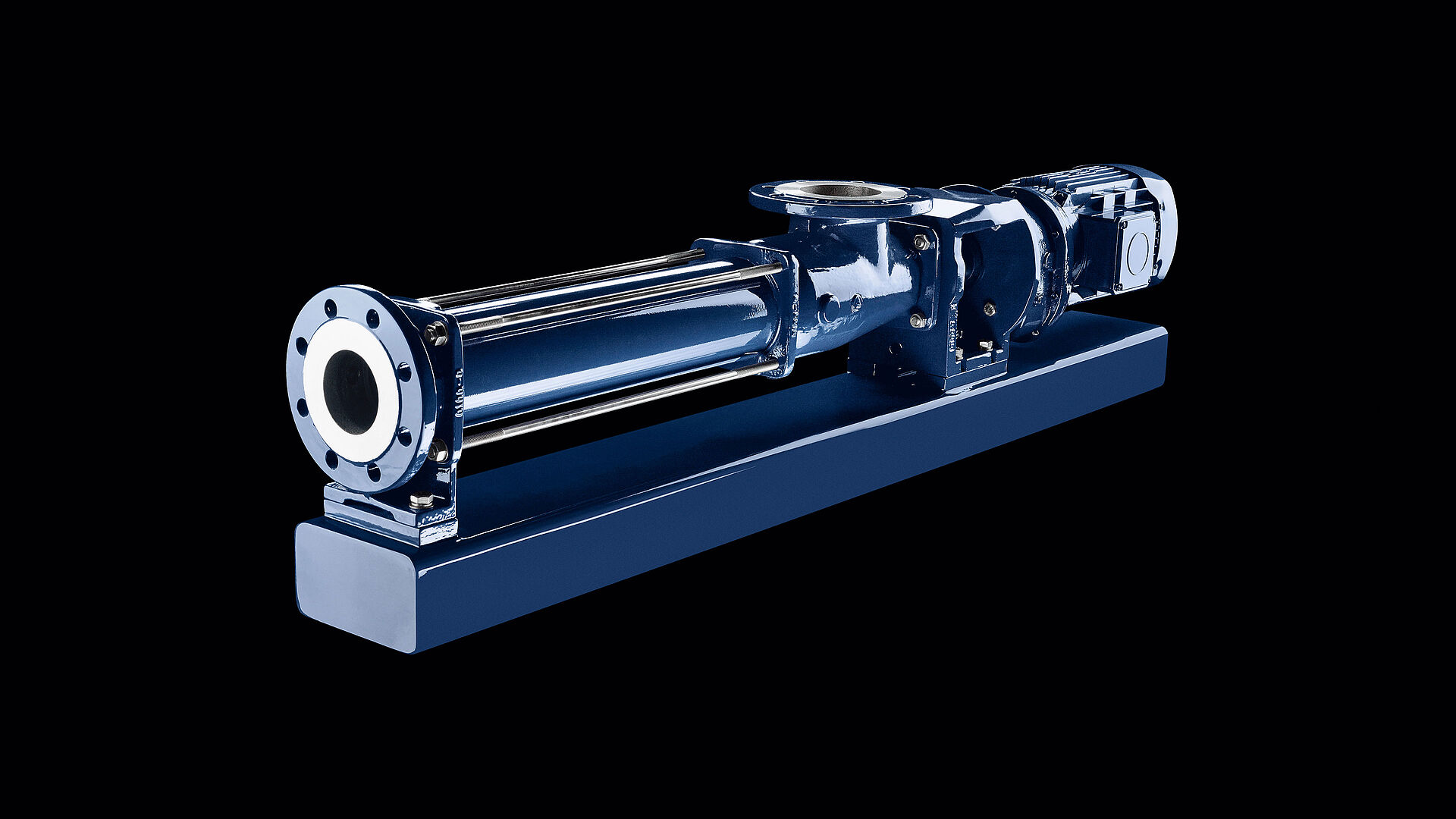

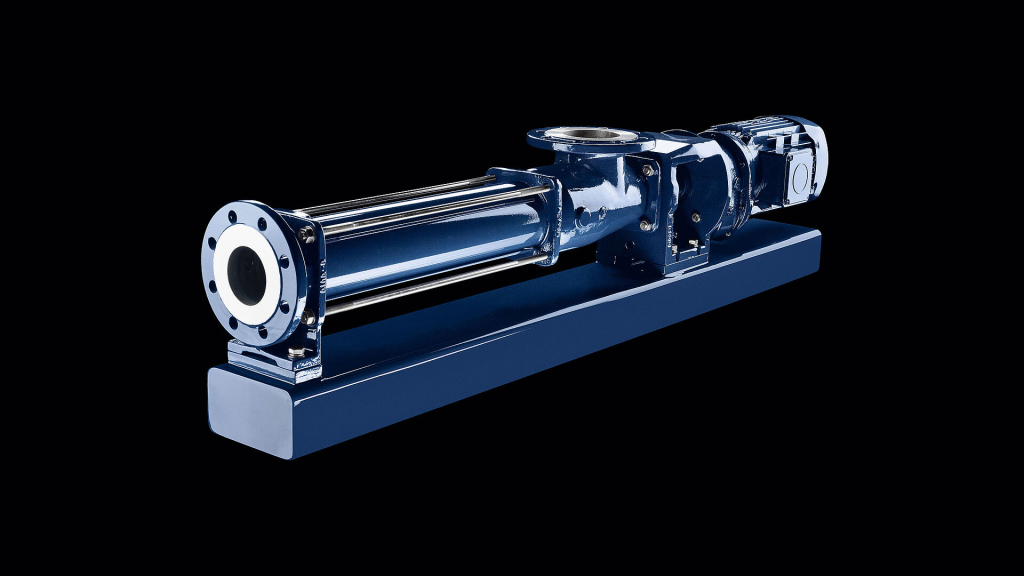

Introduction to BN2-6L

seepex BN2-6L adopts advanced sealing technology. By setting high-performance seals between the rotor and the stator, it not only effectively prevents the leakage of fluid inside the pump, but also helps to extend the service life of the seals. This carefully designed sealing system not only improves the reliability of the pump, but also creates a safer and more hygienic working environment for users.

With its excellent performance and excellent applicability, seepex BN2-6L is widely used in various fields such as chemical, pharmaceutical, and food processing. Whether it is conveying viscous liquids, high-concentration suspensions, or occasions that require sanitation and corrosion protection, BN2-6L can provide reliable and efficient solutions.

The seepex BN2-6L uses high-quality materials that are wear-resistant and corrosion-resistant, providing the pump body with good mechanical properties and chemical stability. The stator part adopts a patented multi-cavity structure, and the precision and stability of the internal cavity are ensured through a high-precision manufacturing process. The rotor part adopts a special spiral shape, which cooperates with the stator cavity to form a closed conveying chamber.

As a customizable pump product, seepex BN2-6 can also be personalized according to the needs of different users to meet various complex working conditions.