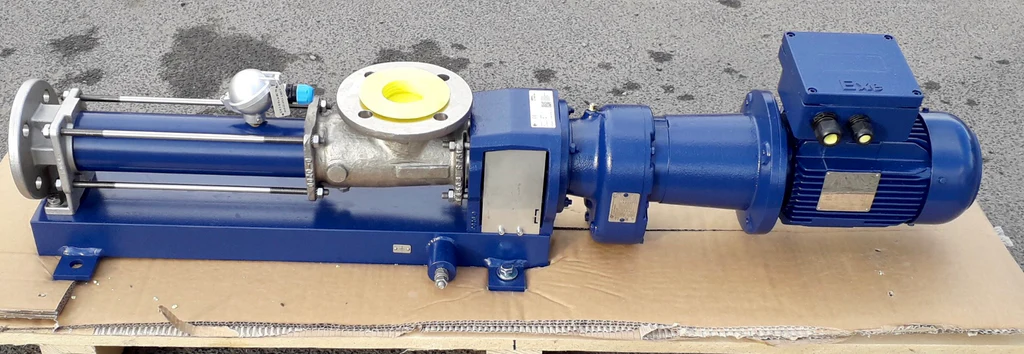

Overview of the Seepex BN Series

Seepex is a globally renowned pump manufacturer, and its BN series is specifically designed for transporting various fluids, especially those that are viscous, abrasive, or contain solid particles. The BN1-12L, as part of this series, inherits Seepex’s tradition of technological innovation and quality control.

Parameters

| Performance: non-blocking | Material: fluorine-lined |

| Drive mode: electric | Flow rate: 51 m3/h |

| Suction diameter: 150 mm | Discharge diameter: 150 mm |

| Speed: 230 rpm | Lift: 120 m |

Design Features of BN1-12L

Efficient Conveying Capacity

The design of the BN1-12L pump emphasizes the efficiency of fluid transportation. Its unique rotor and stator structure allows the pump to maintain a stable flow rate during operation while minimizing energy loss. This design not only enhances the pump’s working efficiency but also extends the equipment’s lifespan.

Outstanding Adaptability

The BN1-12L pump can adapt to various working conditions and is suitable for handling different types of fluids. Whether dealing with high-viscosity liquids or mixtures containing solid particles, the BN1-12L can easily rise to the challenge. This adaptability makes it widely applicable in industries such as food processing, chemicals, and environmental protection.

Convenient Maintenance

Maintenance is a crucial aspect of ensuring the normal operation of any equipment. The BN1-12L has been designed with this in mind, allowing for easy disassembly and assembly of the pump body, significantly reducing downtime. Additionally, the structure of the BN1-12L enables users to perform necessary maintenance and inspections without having to remove the entire pump, greatly enhancing usability.

Application Fields

- Food Industry

In the food processing industry, the safety and hygiene of fluids are of utmost importance. The materials and design of the BN1-12L meet food safety standards, allowing for stable transportation of various food ingredients without compromising fluid quality. Its efficient performance also helps companies enhance production efficiency.

- Chemical Industry

The chemical industry often demands high standards for pumps, especially when handling corrosive or viscous fluids. The BN1-12L, with its corrosion and wear resistance, is an ideal choice for chemical enterprises. It can maintain stable operation under extreme conditions, ensuring smooth production processes.

- Environmental Sector

In environmental projects, the reliability and handling capacity of pumps are critical. The BN1-12L excels in processing complex fluids such as sewage and wastewater, effectively transporting mixtures to treatment facilities and contributing to environmental protection efforts.

Performance Advantages

Energy Efficiency

In the context of global energy conservation and emission reduction, the high-efficiency design of the BN1-12L pump helps companies save significant energy costs. Additionally, it produces relatively low noise and vibration during operation, aligning with environmental standards.

Economic Viability

While the initial investment may be relatively high, the BN1-12L, through its exceptional performance and long service life, can significantly reduce maintenance and replacement costs over time. This makes it highly competitive in terms of economic viability.