Parameters

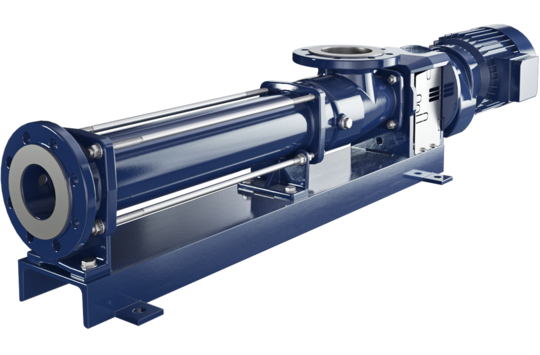

- Brand: SEEPEX

- Drive mode: Electric

- Performance: Wear-resistant

- Conveying medium: Sewage pump, impurity pump

- Pump shaft position: Horizontal

- Number of impellers: Single stage

- Flow rate: 13-83 (m3/h)

- Head: 60m

- Speed: 298 (rpm)

- Suction diameter: DN125 (mm)

- Discharge diameter: DN125 (mm)

- Efficiency: 98%

- Output flow rate: 200

- Weight: 200kg

- Power: 15kW

- Shaft power: 15

- Working temperature: Normal temperature

- Application: Chemical pump

- Material: Cast iron

- Model: BN70-6L

Introduction to BN70-6L

The rotor of the BN70-6L is made of highly wear-resistant materials, ensuring stable performance at high speeds and high loads. The design of the rotor effectively reduces shear forces when the fluid flows in the pump, thereby protecting fluid components that may be vulnerable.

The Seepex BN70-6L is known for its efficient conveying capacity and flexible adjustment options. Users can adjust the pump speed according to specific needs to achieve the required flow and pressure.

In addition, the maintenance cycle of the BN70-6L is long, and the replacement of the rotor and stator is relatively simple, which reduces equipment downtime and improves overall production efficiency. Users only need to check and maintain regularly to ensure the stable operation of the pump.

The Seepex BN70-6L pump is widely used in many industries such as chemical, food, pharmaceutical and environmental protection. In the fields of sewage treatment, slurry transportation and dairy processing, the BN70-6L can win the trust of users with its stable performance.