Food Grade Progressive Cavity Pumps

Q=0.5-50 m³/h (2.2 USGPM – 220 USGPM)

P=0~2.4 Mpa (0~348 psi)

What makes a pump food grade?

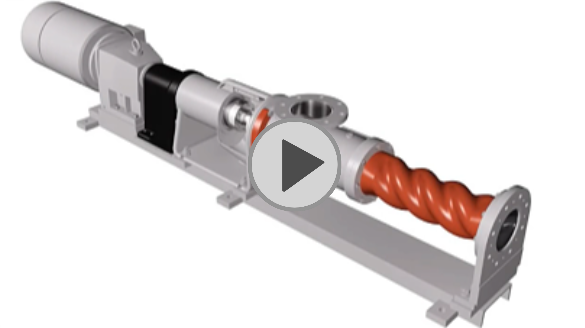

Food grade progressive cavity pump is also a kind of stainless steel progressive cavity pump, its biggest feature is that the material can meet the requirements of food industry. The common material of current passing parts is stainless steel 304 and 316L, and the stator is food grade silica gel. According to the type of medium, there are many choices of its structure.

Progressive cavity pump for food grade (stainless steel food grade pump) refers to a type of progressive cavity pump that is specifically designed to meet the strict food safety standards. Its materials, such as stainless steel and food-grade silica gel, are suitable for handling food products.

The important capabilities include, the continuous, pressure-stable, gentle and low-pulsation pumping and metering in proportion to speed.

Food grade pumps features

- Continuous low pulsation propagation, free from pressure and viscosity fluctuations

- Flow rate proportional to running speed

- The transmission direction can be changed

- Reversible

- Easy to maintain

- Handles both fragile and viscous products

- High suction and self-priming capabilities

- The inlet can be round flange, square hopper and can match with screw propeller

- Flow-favourable, crevice-free free housing design prevents settling of the product

- All wetted surfaces are polished to prevent build-up of the medium and facilitate cleaning (CIP and SIP capability)

- Optional heating of pump housing and stator

- Horizontal and vertical mounting possible

- Service friendliness

- Gentle product conveying

PMV Progressive cavity Pump Parameter List

| Pump Type | Pressure Range (bar) | Capacity Range (m³/h) | Speed Range (rpm) | Inlet Size (G/DN) | Outlet Size (G/DN) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| MJN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 |

| MJN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 |

| MJN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 |

| MJN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 |

| MJN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 |

| MJN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 |

| MJN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 |

| MJN5-3S | 0~18 | 0~3 | 0~250 | 80 | 80 | 5.5 |

| MJN5-4S | 0~24 | 0~2 | 0~200 | 80 | 80 | 7.5 |

| MJN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 |

| MJN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 |

| MJN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 |

| MJN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 |

| MJN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 |

| MJN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 |

| MJN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 |

| MJN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 |

| MJN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 |

| MJN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 |

| MJN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 |

| MJN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 |

| MJN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 |

| MJN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 |

| MJN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 |

| MJN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 |

| MJN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 |

| MJN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 |

| MJN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 |

| MJN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 |

| MJN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 |

| MJN120-2S | 0~12 | 0~100 | 0~270 | 200 | 200 | 45 |

| MJN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 |

| MJN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 |

| MJN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 |

| MJN180-2S | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 |

| MJN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 |

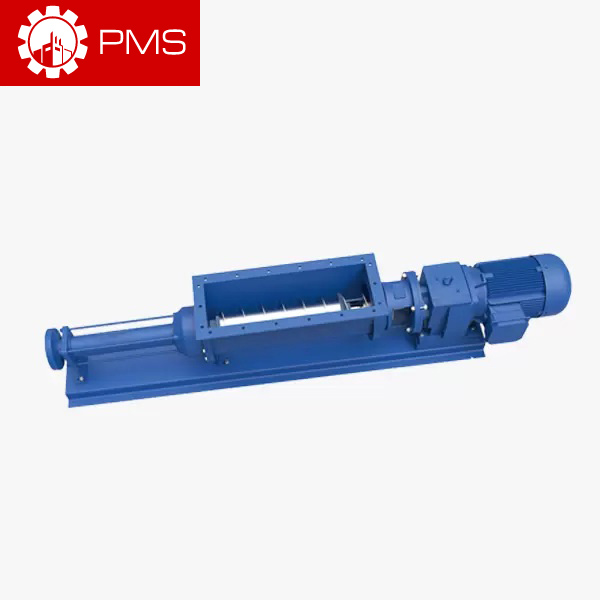

Food grade pumps applications

The food grade progressive cavity pump is employed in the food products, pharmaceutical, cosmetic and chemical/biochemical industries for sanitary applications and optimal cleaning.

People Also Ask