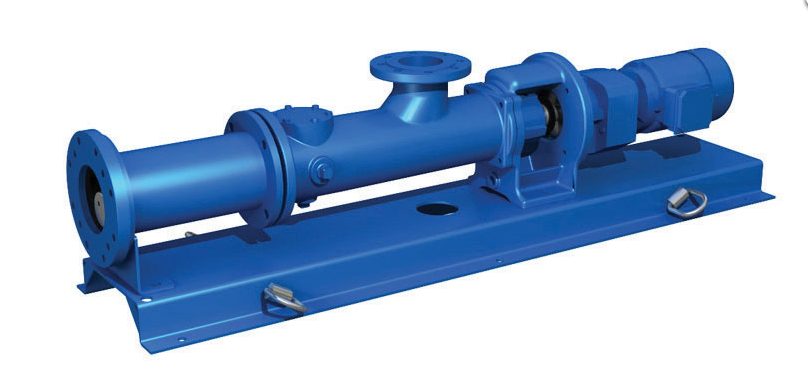

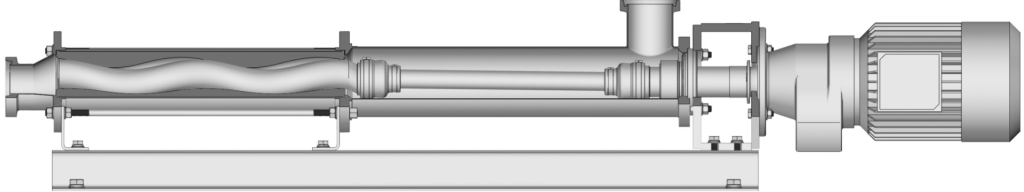

2000WB – CLOSE COUPLED DESIGN

The 2000WB close coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WB model features a traditional close coupled design where the loads are supported by the gear reducer bearings. This design reduces the overall stress that can occur in the gear reducer.

The Description of 2000WB – CLOSE COUPLED DESIGN

The Moyno 2000WB is specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired.

The close coupled design is a type of pump configuration where the motor and pump are integrated into a single unit, resulting in a more compact and efficient system. This design eliminates the need for a separate coupling between the motor and pump, which reduces energy losses and increases overall performance. The close coupled design also simplifies installation and maintenance, making it a popular choice for a wide range of industrial and commercial applications.

Typical Applications

- Municipal Wastewater Treatment

- Pulp and Paper

- Oil and Gas

- Food Waste

- Petrochemical

Features and Benefits of Moyon 2000WB

- Traditional close coupled design

- No shaft bearings

- Thrust and radial loads supported by the bearings in the gear reducer

- Traditional close coupled design

- No shaft bearings

- Thrust and radial loads supported by the bearings in the gear reducer

- Typical Applications

- Municipal Wastewater Treatment

- Pulp and Paper

- Oil and Gas

- Food Waste

- Petrochemical

Parameter Table of 2000WB – CLOSE COUPLED DESIGN

| Fluid | for food products, oil |

| Operation | electric |

| Technology | gear |

| Mobility | stationary |

| Domain | industrial, for wastewater treatment, for petrochemical applications |

| Applications | transfer |

| Other characteristics | radial, flow |

Peple Also Ask