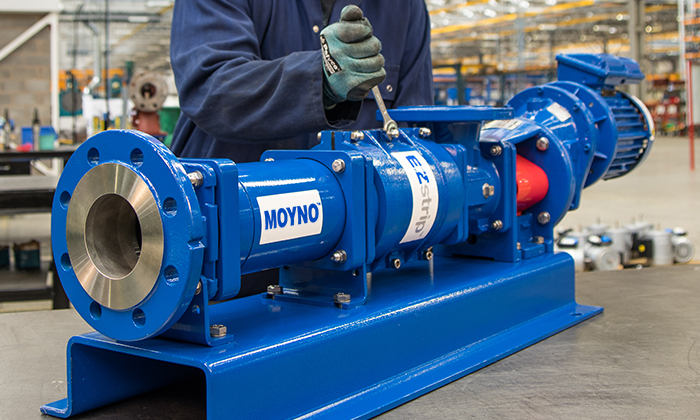

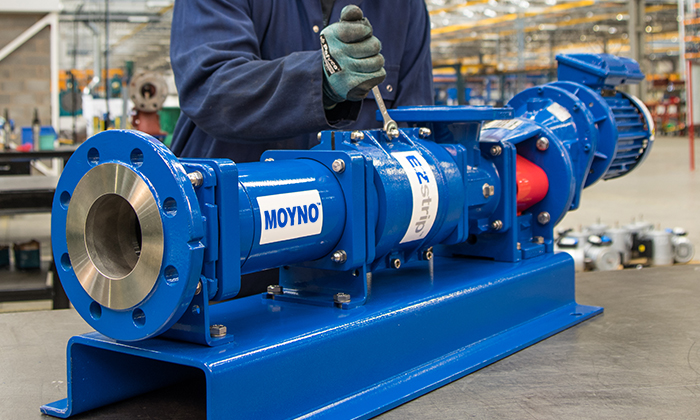

EZstrip™ Transfer Pump

For the newest iteration of our EZstrip™ maintain-in-place progressing cavity pump we designed new features to make maintenance even more user friendly than before. In addition to our patented split suction chamber we’ve removed the tie bars, designed a new positive torque split coupling rod, and added in a captive support foot. That means faster, easier maintenance for you. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

The Description of EZstrip™ Transfer Pump

The EZstrip is the latest revolutionary new pump design which can be ‘Maintained-in-Place’ (MIP), making a day-long maintenance operation become a 30 minute job.

This innovative pump is the biggest leap forward in progressing cavity (PC) pump design for 30 years and is an extension of Mono’s popular Compact C Range. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

The Application of EZstrip™ Transfer Pump

- Saltwater disposal truck offloading

- Domestic and industrial effluent

- Hydrated lime slurry

- Sludge

- Shear sensitive latex emulsion

- Milk curds, sauces, and fruit juices

- Industrial chemicals and detergents

- Starch slurries

- Coating clays, gypsum, and silicate

- Paper stocks

- Agricultural slurries

Features and Benefits

- Available in cast iron or stainless steel, with a choice of rotor and stator materials, including WRAS compliant elastomers

- Quick and easy de-rag in place

- Requires only spanners and an Allen key to maintain

- Reduced maintenance downtime and increased labor savings

- No need to disconnect suction and discharge pipework

- Eliminates dismantling lengths

- Can be retrofitted into existing Compact C pump installations

EZstrip Transfer Pump Specifications and Dimensions

| Capacity | 991 gal/min (up to 225 m3/hr) |

| Pressure | 174 psi (up to 12 bar) |

| Temperature | 14 to 212 °F (-10 to 100 °C) |

People Also Ask