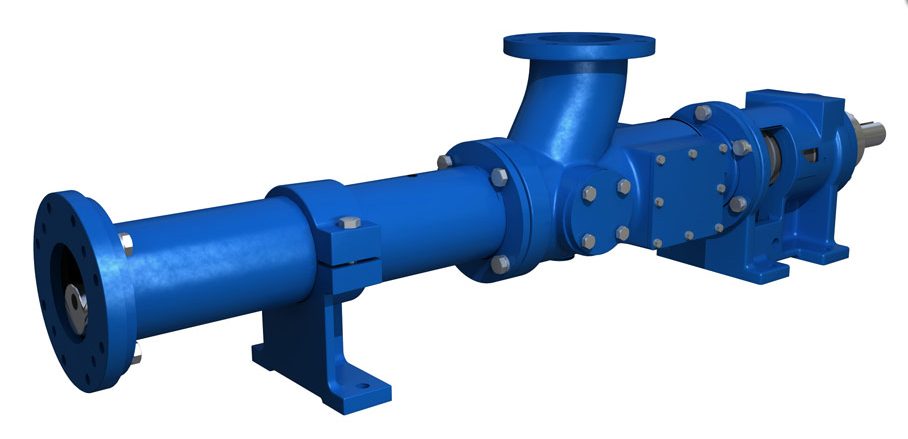

G4 – 45 INLET DESIGN

The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product.

Description of G4 – 45 INLET DESIGN

The Moyno Model G4-45 Inlet Design Pump is a highly efficient positive displacement pump that is designed to handle a wide range of fluids with varying viscosities. It features a unique inlet design that allows for smooth, non-pulsating flow and minimizes shear forces, making it ideal for handling shear-sensitive fluids. The pump’s compact design and low maintenance requirements make it an excellent choice for a variety of applications, including chemical processing, food and beverage production, and wastewater treatment.

Typical Applications

- Pharmaceutical pastes

- Heavy petroleum sludges

- Plasticizers

- Municipal sludge in excess of 30% solids

- Paper stock in excess of 12% solids1

Benefits of G4 – 45 INLET DESIGN

- Universal joint that is out of the fluid flow path for unobstructed flow to the pump cavity inlet

- Lower overall system pressure

- Constant, non-pulsating flow imparts less stress on piping machinery and drive systems

- Patented auger feed on the rotor head smoothly stuffs product directly into the cavity without obstruction

- Rotor configuration is designed to enhance flow of high solids content materials and optimize volumetric efficiency

People Also Ask