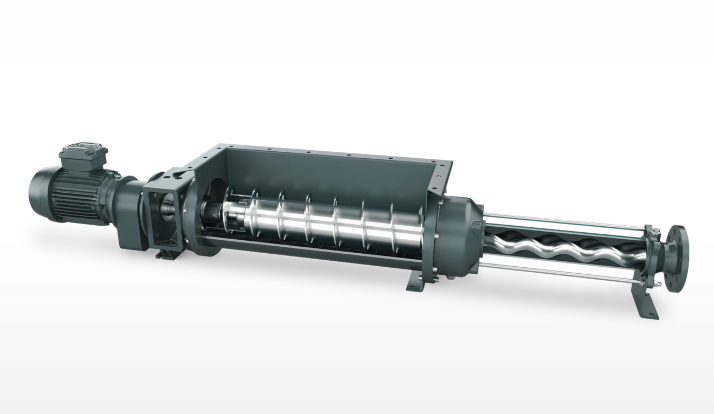

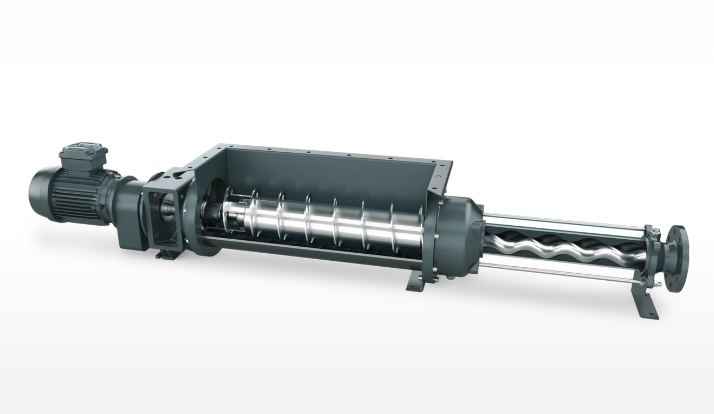

Efficient Handling of Viscous and Crumbly Substances

The NEMO® BF Hopper Pump With Feed Screw is an effective solution for handling highly viscous and crumbly substances that do not tend to form bridges. Its design allows for efficient feeding and prevents clogging, ensuring a smooth and controlled material flow. With its robust construction and advanced features, it provides reliable performance in industries such as food processing, chemicals, and pharmaceuticals.

Description of NEMO® BF Hopper Shaped Pump

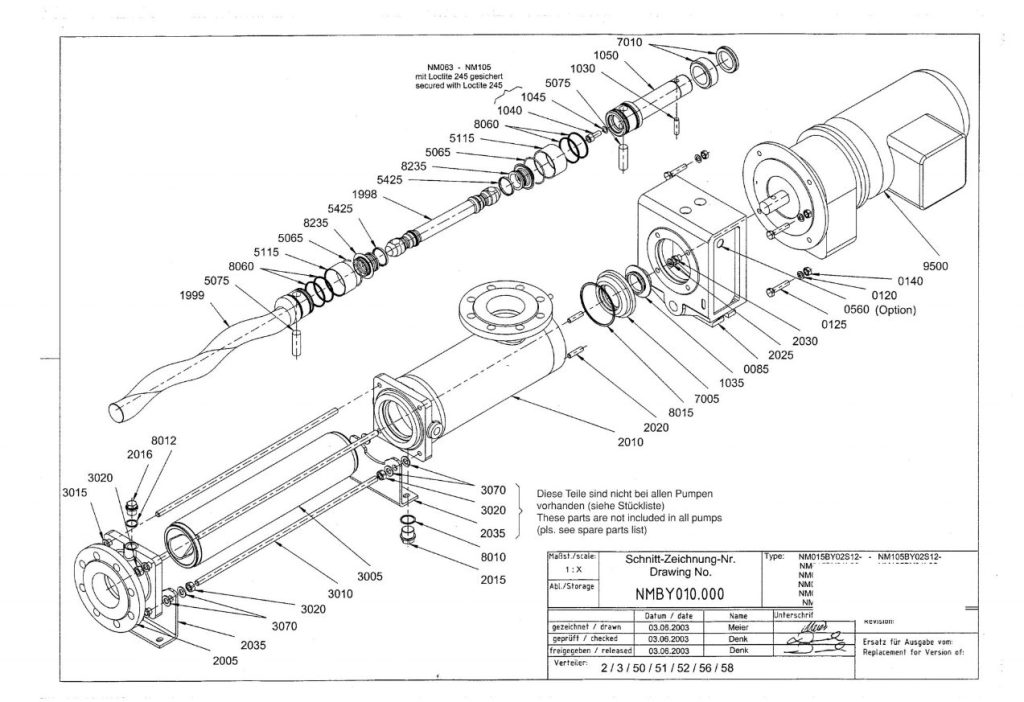

For optimum product feed into the conveying elements, the netzsch pump housing is designed with an enlarged, rectangular feed hopper and conical force-feed chamber as well as a special coupling rod with patented, positioned conveying screw. This also ensures the smooth conveying of solids containing shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials. The NETZSCH NEMO Pump is particularly compact and economical in block construction with flanged drive.

Application of NEMO® BF Hopper Shaped Pump: Efficient Handling of Viscous and Abrasive Materials

The NEMO® BF Hopper Shaped Pump is commonly used for applications involving the transfer and handling of highly viscous, abrasive, and shear-sensitive materials. It finds use in industries such as wastewater treatment, food processing, and chemical manufacturing. The pump’s hopper design enables efficient feeding and conveying of solid or semi-solid substances.

NEMO® BF hopper shaped pump ensures smooth conveying

This also ensures the smooth conveying of solids containing shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials. The NEMO® BF is particularly compact and economical in block construction with flanged drive.

People Also Ask