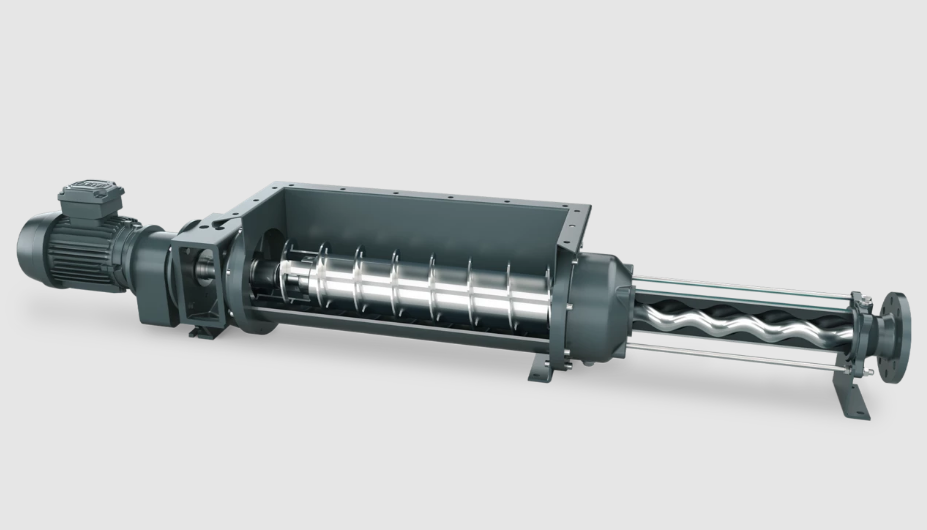

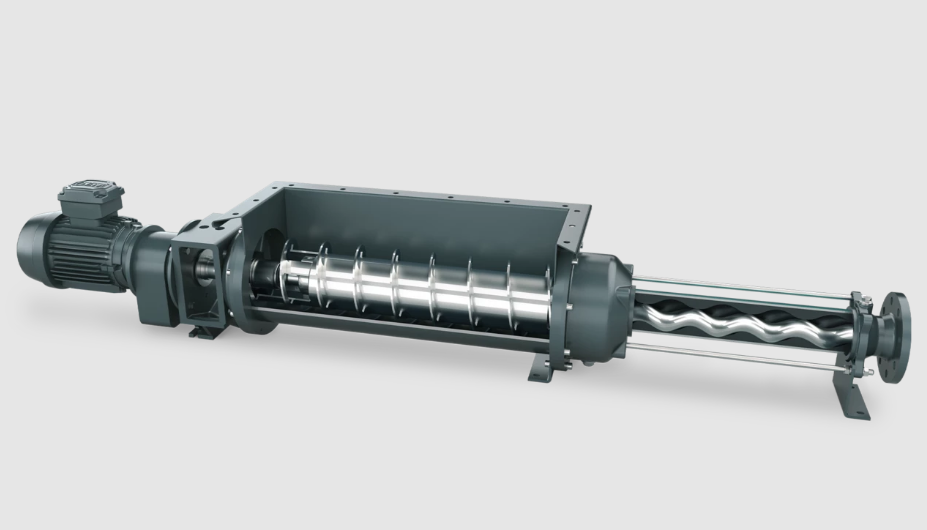

NEMO® BF Open Hopper Pumps

The NEMO® BF open hopper pump is used in all industrial markets to provide continuous, pressure-stable, gentle and low-pulsation handling with metering in proportion to rotation speed. This pump is used primarily for highly viscous, compacted and crumbly substances that do not have a tendency to bridge.

Compact Progressive Cavity Pump Design

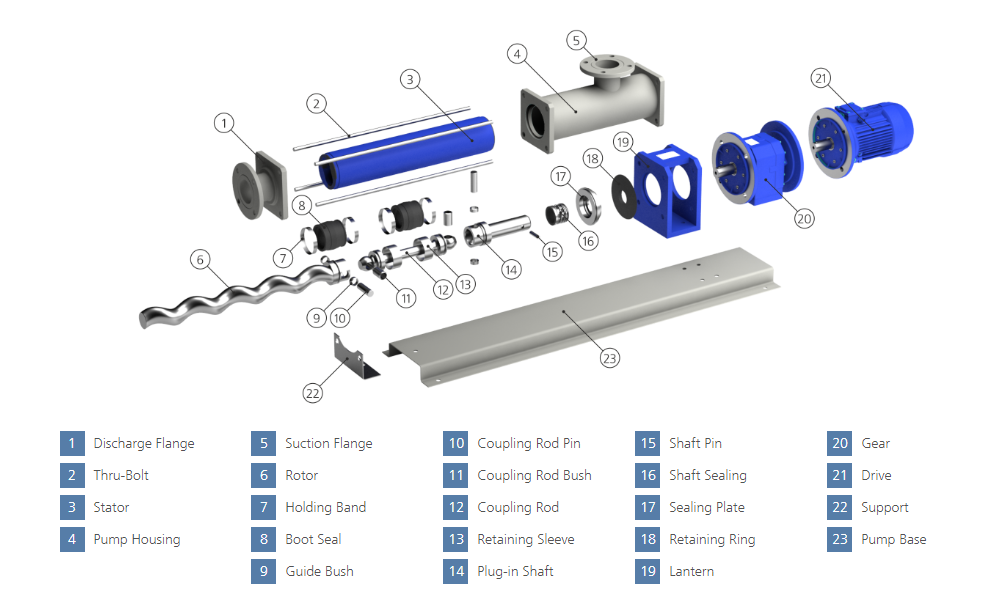

For optimal feed into the pumping elements, the pump housing is designed with an enlarged, rectangular hopper and conical force-feed chamber as well as a special coupling rod with a patented, horizontally positioned auger.

In block construction, this pump is particularly compact and economical.

NEMO® BF Open Hopper Progressing Cavity Pumps offer you:

- gentle product handling

- pump connections in accordance with national and international standards, as well as in specially designed models

- easy serviceability

Features of the NEMO® BF Open Hopper Progressing Cavity Pump

- pump housing with enlarged rectangular hopper

- conical force-feed chamber

- special coupling rod with patented, horizontally positioned auger

- continuous low-pulsation handling unaffected by fluctuations in pressure and viscosity

- capacity in proportion to rotation speed with precision metering over a wide speed range

- high pressure capability without valves

- stator with hopper-shaped entrance for optimal filling of the conveying chamber

Advantages of the NEMO® BF Open Hopper Progressing Cavity Pump

- modular design

- a wide variety of materials

- robust and compact block construction

- the right joint for any application

- standard mechanical seal, other seals optional

People Also Ask