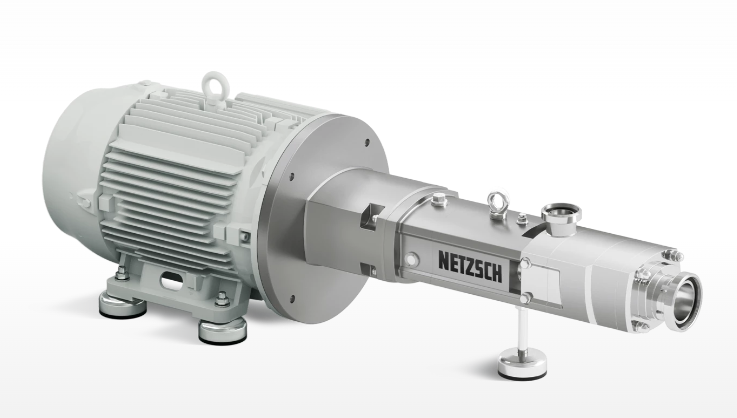

NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design

The NOTOS® 2NSH hygienic twin screw pump in FSIP® (Full Service in Place) design impresses with gentle pumping, low pulsation, simple maintenance and ease of operation in the process.

The description of NOTOS® 2NSH Hygienic Twin Screw Pump

With its stable and compact housing and efficient design, the twin screw pump is ideal for industries that value high quality, maximum productivity and excellence throughout the process: A reliable solution tailored to the individual requirements of a application. It is designed for hygienic applications to optimally convey media with higher viscosity at high working pressures up to 16 bar or 230 psi. Chocolate, fruit juices or fruit yoghurt, for example, are pumped while retaining their consistency and natural properties without any loss of quality. The FSIP® concept makes it possible to completely dismantle and reassemble the spindles and mechanical seal without removing the pump from the production line. Downtimes for maintenance work can thus be significantly reduced. This intelligent, technical solution ensures even more convenience and safety in your processes.

Efficient and Hygienic Pumping with NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design

The NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design is ideal for a wide range of hygienic applications. The pump’s design ensures gentle product handling and delivers high flow rates at low pulsation levels, making it suitable for use in the food, beverage, pharmaceutical, and personal care industries. With its Full Service in Place (FSIP®) design, maintenance and cleaning are quick and easy, reducing downtime and increasing productivity. Whether it’s for transferring delicate liquids or viscous materials, the NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design offers reliable and efficient performance that meets the stringent hygienic standards required in these industries.

The NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design offers the following features

- Hygienic Design: The pump is specifically designed to meet strict hygiene standards, making it suitable for applications in food, beverage, pharmaceutical, and other sensitive industries.

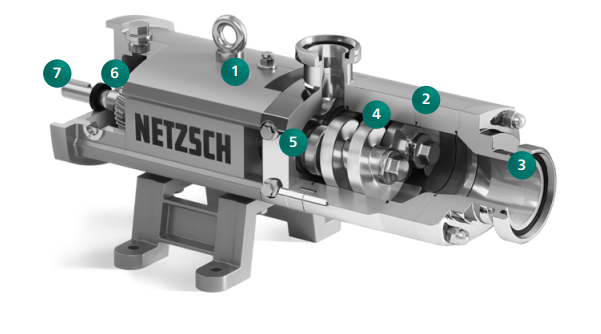

- Twin Screw Technology: The pump utilizes a twin screw mechanism, ensuring smooth and consistent fluid handling with minimal pulsation. This design allows for gentle product handling, reducing the risk of product degradation or damage.

- FSIP® Design: The pump features a Full Service in Place (FSIP®) design, allowing for easy and efficient maintenance and cleaning. This design eliminates the need for disassembling the pump, saving time and reducing downtime.

- Versatility: The pump is capable of handling a wide range of viscosities and temperatures, making it suitable for various applications. It can effectively handle both low and high viscosity fluids, ensuring reliable and efficient operation.

- CIP and SIP Capabilities: The pump is equipped with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) capabilities, facilitating thorough cleaning and sterilization of the pump and its components. This ensures compliance with strict hygiene standards and helps maintain product integrity.

- High Efficiency: The pump is designed for optimal efficiency, delivering high flow rates and maintaining consistent performance. This results in energy savings and reduced operating costs.

- Compact and Space-Saving: The pump has a compact design, allowing for easy installation in tight spaces or existing process lines. Its space-saving design does not compromise on performance or reliability.

People Also Ask