What are Progressing Cavity Pumps?

Progressing cavity pumps, also known as PC pumps or screw pumps, are a type of positive displacement pump that uses a single rotating element to move fluids through a sequence of small, fixed-shape cavities. They are commonly used in various industries for fluid transfer applications due to their ability to handle viscous and abrasive materials without causing damage to the pumped media.

The description of Progressing Cavity Pumps

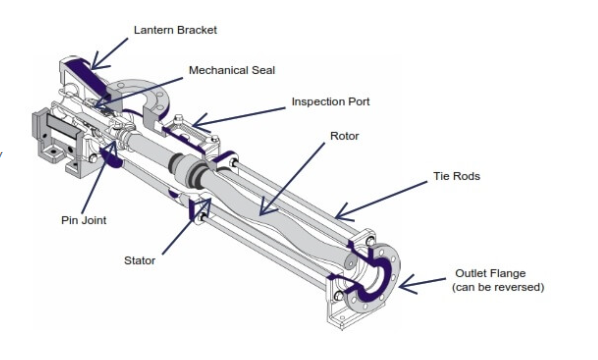

Progressing cavity pumps, also known as PC pumps or screw pumps, are positive displacement pumps that use a single rotating element to move fluids through a sequence of small, fixed-shape cavities. The design of the pump enables it to handle viscous and abrasive materials without causing damage to the pumped media.

The features of Progressing Cavity Pumps

Progressing cavity pumps offer several features that make them an ideal choice for many fluid transfer applications. They are versatile in handling a wide range of fluids, including low-to-high viscosity liquids, slurries, and solids-laden materials. Due to their positive displacement design, they provide constant flow rates at a relatively low speed, resulting in less energy consumption compared to other types of pumps. Their gentle pumping motion helps preserve the integrity and quality of delicate products like food, pharmaceuticals, and chemicals. Additionally, they have minimal pulsation due to their smooth and steady flow.

The Application of Progressing Cavity Pumps

Progressing cavity pumps are commonly used in various industries for fluid transfer applications. In the oil and gas industry, they are ideal for both upstream and downstream applications, including crude oil transfer, drilling mud circulation, and hydraulic fracturing. In the food and beverage processing industry, progressing cavity pumps are used to transfer a variety of food products, such as dairy, juice, syrups, and sauces. In chemical and pharmaceutical manufacturing, they are suitable for transferring sensitive and hazardous substances, including acids, bases, solvents, and vaccines. Moreover, their robust construction and ability to handle solids make them an excellent choice for municipal and industrial wastewater treatment systems.

People Also Ask