What Is a Progressive Cavity Pump?

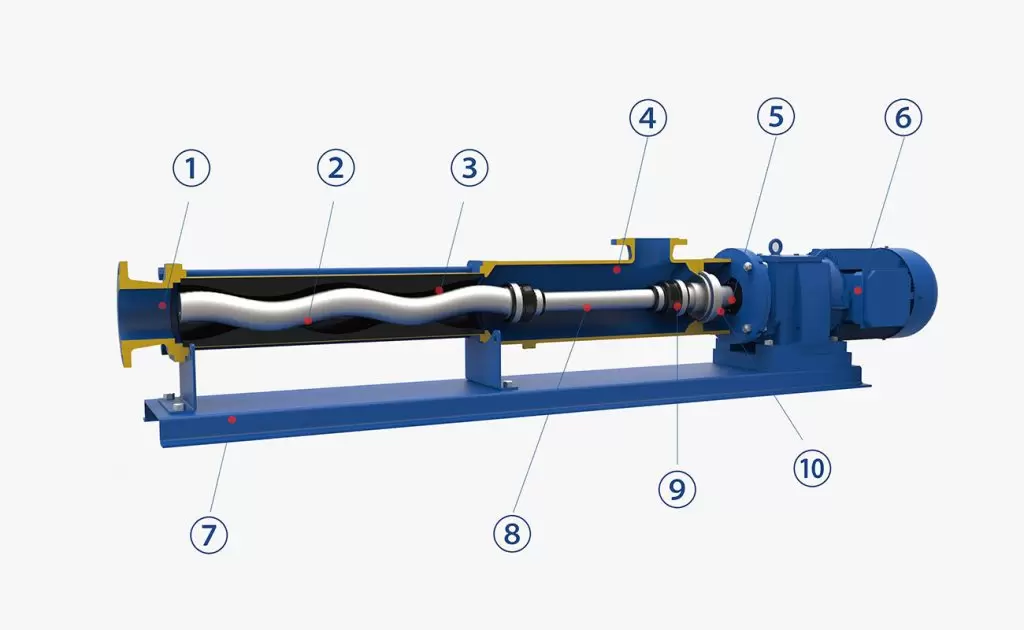

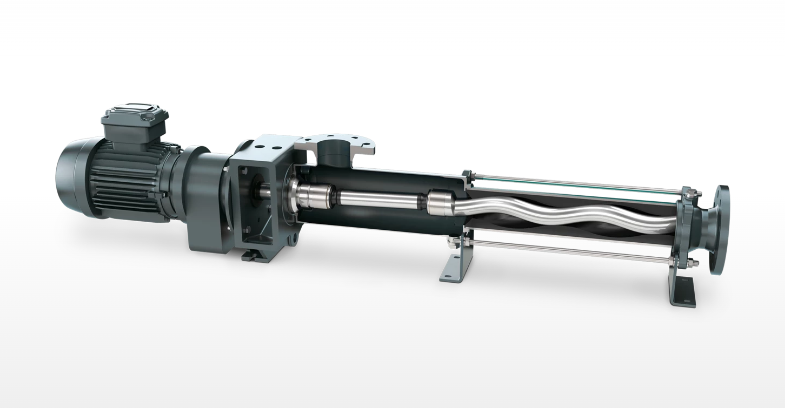

A progressive cavity pump is a type of positive displacement pump that works on the basis of the progress of the rotor. The helical rotor and rubber-lined stator are the main components of this cavity pump. A progressive cavity pump is a versatile pump that can handle a variety of jobs and is specially designed to meter chemicals and handles highly viscous, abrasive, or shear-sensitive materials and other extremely tough pumping applications.

A progressive cavity pump is widely used. So it has many other different names, such as PC pumps, progressing cavity pumps(PCP), cavity pumps, screw pumps, eccentric screw pumps, etc.

Many famous pump brands are popular with progressive cavity pumps, such as NETZSCH, SEEPEX, MOYNO, etc.. Therefore, there is a big request for replaceable spare parts In the market. Including NETZSCH Pump Parts, MONO Pump Parts, SEEPEX Pump Parts, etc.

What are the specific applications of progressive cavity pumps?

Progressive cavity pumps are versatile and they can be used in different conditions with various applications. Some main PC pump applications are listed below for your information.

- Wastewater

- Pulp and Paper

- Metering and Dosing

- Chemical Manufacturing

- Lubrication Oil Pumping

- Grout or Cement Pumping

- Environmental Technology

- Food and Beverage Processing

- Oil Pumping/Petroleum Production

- Limited Energy Well Water Pumping

- Sewage, Sludge, and Slurry Pumping

How does a progressive cavity pump work?

As a positive displacement pump type, progressive cavity pumps ( also called PC pumps or PCP) are flow-creating devices. They forward fluid at a consistent speed no matter how the pressure varies on the inlet end.

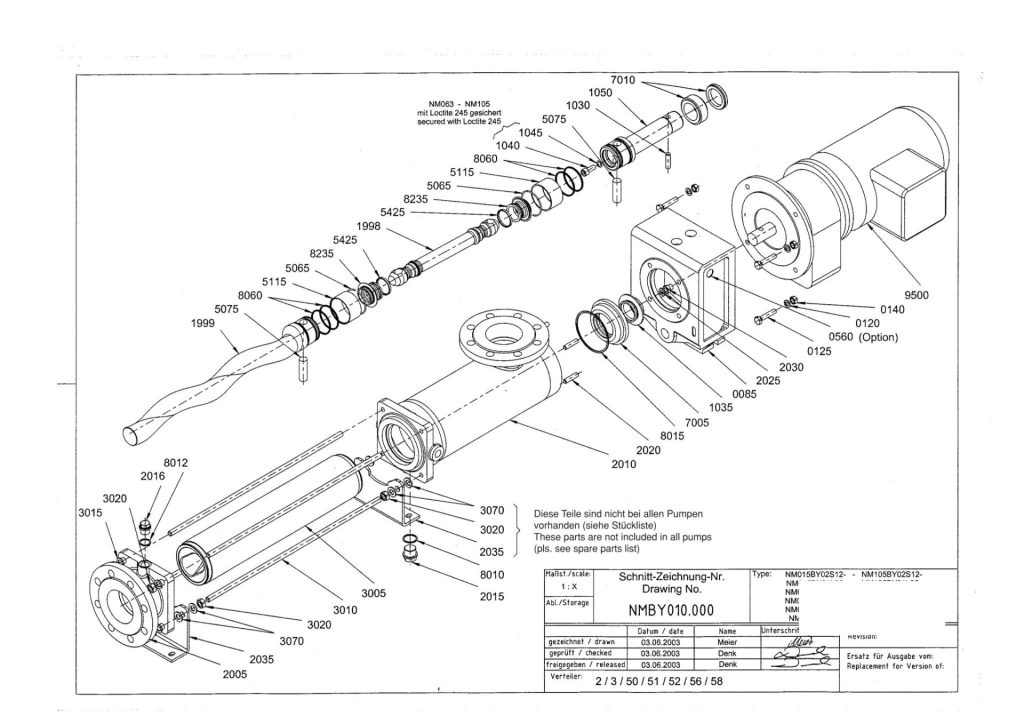

PC pumps draw fluid in through a suction inlet which feeds into an elongated casing. Within the suction casing, there are a helical rotor and rubber-lined stator assembly. The rotor helix is offset to the stator. As the rotor turns and contacts the internal surface of the stator, it leaves conveying spaces between the hollow stator and the helical rotor. Then the viscous medium can move continuously from the inlet to the outlet side. That is generally how a progressive cavity pump works.

Are the PC pumps allowed to dry run?

PC pumps are highly effective at pumping different types of fluids as long as you keep them in ideal working conditions. One main reason for these pumps to fail is when they lose the necessary lubrication to keep the rotor and stators operating correctly.

When there is a loss of lubrication of the pumped fluid, it causes excess friction and high temperature on the surface of the stator. Then the pump stator would be destructed by dry running. Please remember that dry running is the most common cause of pump failure. So PC pumps are not allowed to dry run and we should take some actions to prevent the progressing cavity pump from dry running.

How to prevent the progressing cavity pump from dry running?

Different PC pump manufacturers designed some accessories that act as a safeguard against this. Common methods of preventing the PC pump from dry running are using presence/absence sensors, stator temperature probes, and nonintrusive pressure sensors.

Presence/absence sensors can protect pumps by detecting the absence of fluid flowing into the suction port. When supply fluid is not detected for a preset period of time, the system would deactivate the pump motor starter or other critical process equipment. This sensor is reliable protection against dry running since it can stop the pump before dry running happens.

Stator temperature probes are another way to protect the progressive cavity pump against dry running. Because it has a thermistor sensor and sleeve inserted into the pump stator to measure the temperature between the rotor and stator. When a preset temperature is reached, an electronic temperature regulator would deactivate the motor starter.

For abrasive applications, a few minutes of dry running would result in accelerated wear of the stator. According to our experiences, the rotor and stator actually have a dry run for several minutes before the temperature probes detect the increased heat.

Well, there is another effective way to prevent dry running of the progressive cavity pumps. It is a non-intrusive pressure sensor. This kind of sensor is located at the pump outlet. The pressure detection works over the entire pipe circumference to ensure that coatings, settled material, or bridging will not affect the pressure readings. In addition, a liquid-filled gauge can be an added feature to allow visual monitoring of pressure.

What purposes do progressive cavity pumps serve?

Progressive cavity pumps (also known as PC pumps) are used to pump fluids that cannot be handled by other types of pumps. PC pumps typically serve the following purposes.

- Pumping heavy or viscous fluids;

- Pumping shear-sensitive materials;

- Pumping, dosing, and metering chemicals;

- Pumping materials that contain abrasive particles;

- Pumping fluids in applications that require varied flow rates