Introduction to Screw Pump Diagram

A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high viscosity fluids, solids-laden liquids, and low shear rate applications.

Description of Screw Pump

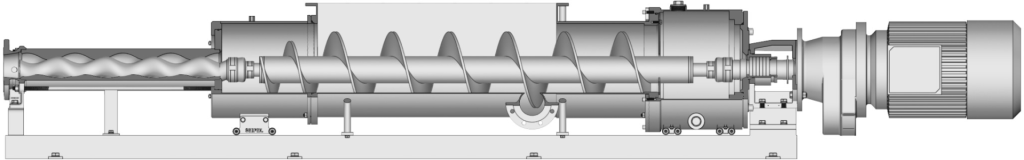

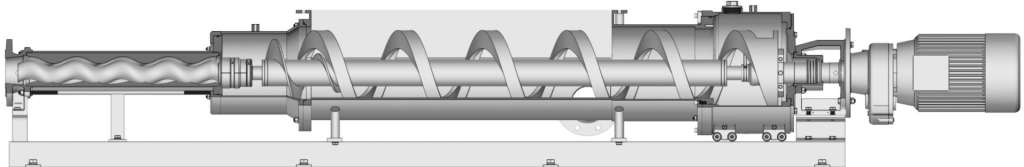

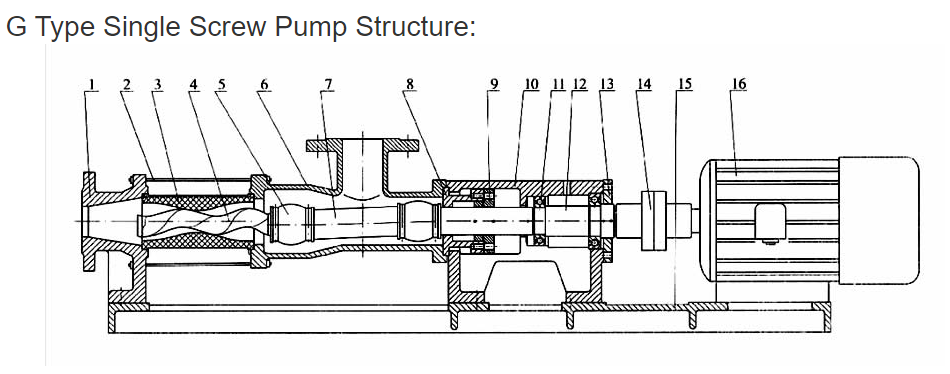

A screw pump consists of two or more intermeshing screws that rotate in opposite directions within a cylindrical housing. The fluid enters at the suction end and moves axially along the length of the screws, creating a continuous flow that pushes the fluid towards the discharge end of the pump. The precise geometry of the screw profiles determines the pumping characteristics, such as flow rate, pressure, and efficiency.

Application of Screw Pump

Screw pumps are used in a variety of industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. They are ideal for handling highly viscous liquids, abrasive slurries, and delicate materials that require gentle pumping action. Some common applications of screw pumps include transfer, loading and unloading, metering, feeding, and circulating fluids.

Features of Screw Pump

- High efficiency and low pulsation flow

- Stable performance over a wide range of operating conditions

- Self-priming and capable of handling entrained air and gases

- Minimal wear and tear on the pump components

- Easy maintenance and simple design with no valves or complex parts

Types of Screw Pumps

There are several types of screw pumps available in the market, each with its unique features and applications. The three most common types are:

Twin Screw Pump: It consists of two parallel intermeshing screws that rotate in opposite directions. It is suitable for handling high viscosity fluids, such as crude oil, heavy fuel oils, and bitumen.

Water Screw Pump: It is a variant of the twin screw pump designed specifically for pumping water and other low viscosity liquids. It has wider screw pitches and lower rotational speeds than the traditional twin screw pump.

Single Screw Pump: It consists of a single rotating screw that meshes with a stationary elastomer stator. It provides a non-pulsating flow and is ideal for handling abrasive slurries, polymers, and viscous fluids.