SAFE OIL AND GAS PUMPING

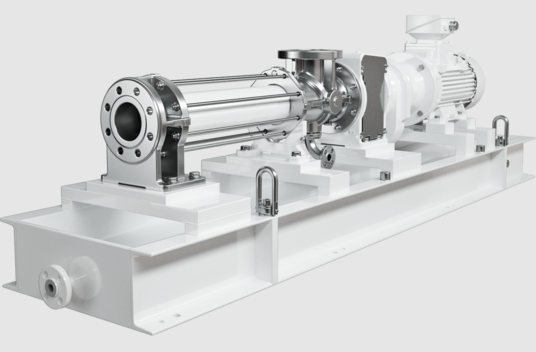

Built for the highest expectations: BNA progressive cavity pumps are designed for the high requirements of the oil and gas industry. With their robust, heavy-duty cast housings, they optimally fulfill the requirements of the American Petroleum Institute (API). Corrosion-resistant materials such as Super Duplex are standard.

Description of SEEPEX BNA Pump According to API 676 Standard

The SEEPEX BNA pump is a powerful and reliable solution for a wide range of applications in the chemical, food, and pharmaceutical industries. Built to meet the rigorous API 676 standard, this pump provides exceptional performance, efficiency, and durability.

With its modular design and numerous configuration options, the SEEPEX BNA pump can be customized to meet specific operational requirements. Its advanced features include a flexible coupling drive, stainless steel construction, and a rotor/stator system that ensures gentle product handling.

Designed with ease of use and maintenance in mind, the SEEPEX BNA pump is easy to install, operate, and service. Its minimal downtime and low operating costs make it a cost-effective choice for businesses looking to improve their productivity and profitability.

Overall, the SEEPEX BNA pump is an outstanding example of quality engineering and innovation, providing superior performance and reliability in a compact and versatile package.

Applications of SEEPEX BNA – API 676 Standard Pump

The SEEPEX BNA pump is a versatile solution that can be used in a wide range of applications across various industries. Its advanced features and exceptional performance make it an ideal choice for many different pumping needs.

In the chemical industry, the SEEPEX BNA pump can be used for the safe and efficient handling of hazardous chemicals and corrosive materials. Its stainless steel construction and gentle product handling capabilities ensure that even the most delicate liquids are handled with care.

The food industry can benefit from the SEEPEX BNA pump’s ability to handle viscous and abrasive materials with ease. Its flexible configuration options allow for customization to specific needs, while its hygienic design ensures safe and sanitary operation.

In the pharmaceutical industry, the SEEPEX BNA pump can be used for precise dosing and reliable transfer of sensitive liquid products. Its modular design and flexible coupling drive ensure accurate and efficient operation.

Overall, the SEEPEX BNA pump is a versatile and reliable solution for a wide range of applications, making it an excellent choice for businesses looking to improve their productivity and efficiency.

Safe

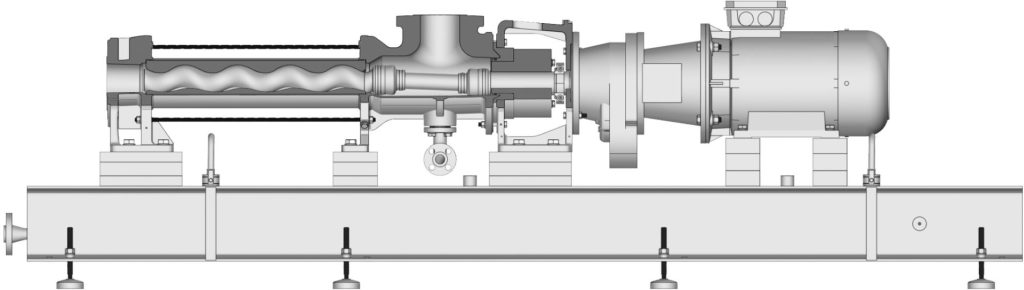

Housing sections made from robust, heavy-duty Super Duplex stainless steel, with flange-mounted emptying. The base plate contains a leakage pan to collect the liquid that escapes during maintenance.

Pressure-resistant

All pump parts cast or machined, no weld seams in contact with fluid. Generously dimensioned wall thicknesse and ribbing for high pressure stability, exceptional rigidity and quiet running. High flange loads possible.

API-compliant

All parts designed in compliance with API 676, flanges compliant with ASME B16.5, mechanical seals compliant with API 682. Flushing plans compliant with API 682 available as accessories.

Particularly high-quality

All parts made from AST material with complete traceability; corrosion-resistant materials compliant with NACE MR0175, or optionally compliant with NORSOK M-630.

Time-saving

Low inspection requirements and significantly reduced documentation thanks to API-compliant design and avoidance of welding.

People Also Ask