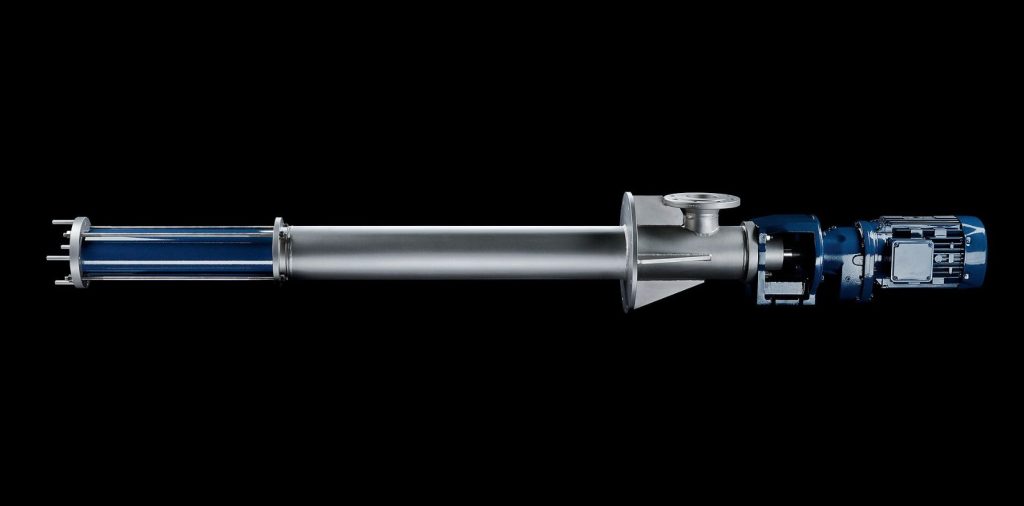

E – SEMI-SUBMERSIBLE PUMPS POISED TO DIVE

SEEPEX semi-submersible pumps empty barrels, pits, basins and containers – efficiently, thoroughly, and environmentally friendly. They can even withstand the demands of abrasive or corrosive media with low to high viscosity. This makes them a cost-effective alternative to conventional pump systems, particularly in applications with critical suction heads or limited installation space.

Efficient and Reliable: Introducing SEEPEX E – Semi-Submersible Pumps

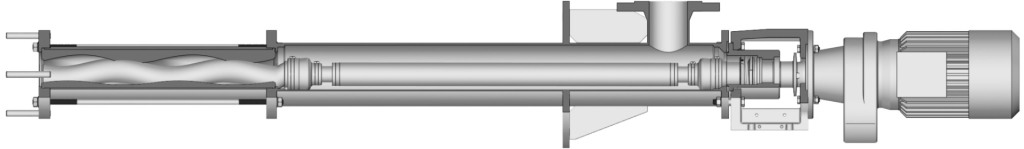

SEEPEX E – SEMI-SUBMERSIBLE PUMPS are highly efficient and reliable pumps designed for use in a variety of applications, including wastewater treatment, food processing, and chemical processing. These SEEPEX pumps are semi-submersible, meaning that they can operate partially submerged in liquid, making them ideal for use in deep sumps and areas with high levels of solids or slurry. They are also easy to install and maintain, with a low-maintenance design that helps reduce downtime and operating costs.

Application of SEEPEX E – Semi-Submersible Pumps

SEEPEX E – Semi-Submersible Pumps are versatile and reliable pumps that can be used in various industries. With their semi-submersible design, these seepex pumps are suitable for applications where a fully submersible pump is not required or desired.

Some common applications of SEEPEX E – Semi-Submersible Pumps include transferring liquids and slurries in the chemical, pharmaceutical, food and beverage, and wastewater treatment industries. They are also used for dosing and metering applications in the agricultural and mining industries.

With their ability to handle viscous and abrasive materials with high precision and efficiency, SEEPEX E – Semi-Submersible Pumps are an ideal choice for many industrial applications.

Different installation depths

Available in different designs for different immersion depths – all the way through to fully submersible pumps

Environmentally friendly

Suitable for installation in closed systems and compliant with environmental protection regulations thanks to its gas-tight domed lid

Optimizing processes

It is possible to increase the NPSHa for liquids with low vapor pressure without cavitation – by installing the pump in a vessel

Versatile applications

Ideal for numerous applications in the chemical industry, but also for certain conveying processes in the food, pharmaceutical and cosmetics industries

Gentle conveyance

Low-pulsation, constant flow rate for consistent product quality

People Also Ask