INCORPORATES VARIABLE FREQUENCY DRIVE (VFD) WITH ELECTRONIC PROGRAMMING MODULE (EPM) MEMORY CHIP

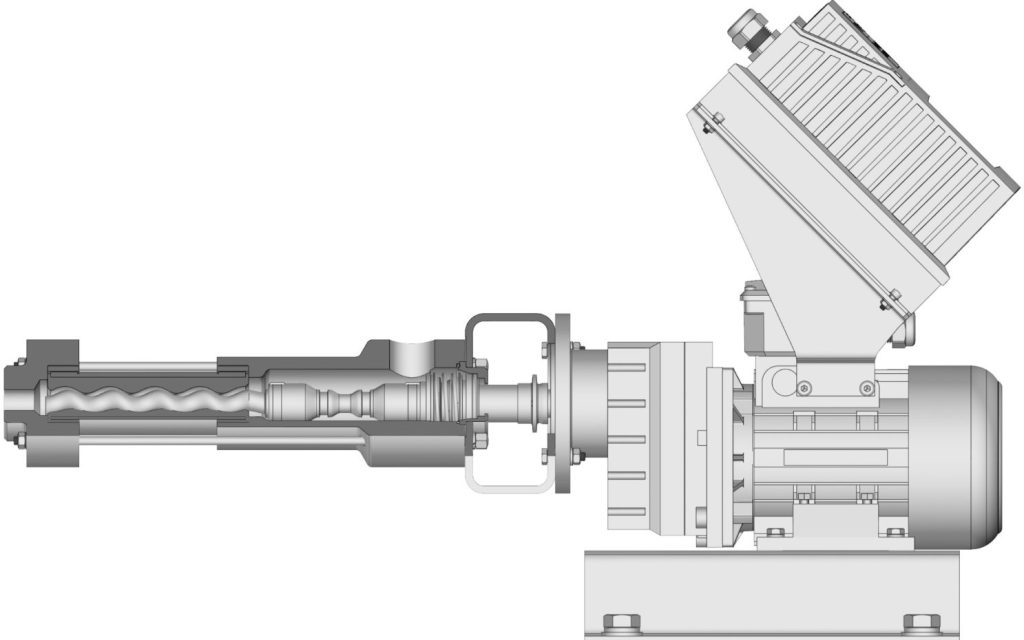

The Intelligent Metering Pump (IMP) design incorporates a gear reducer and a programmable vector drive in a compact design for precise metering. Metering parameters can be pre-configured on an Electronic Programming Module (EPM) memory chip, making conversion from a previous drive to a new drive or a change in parameters as easy as inserting the EPM chip.

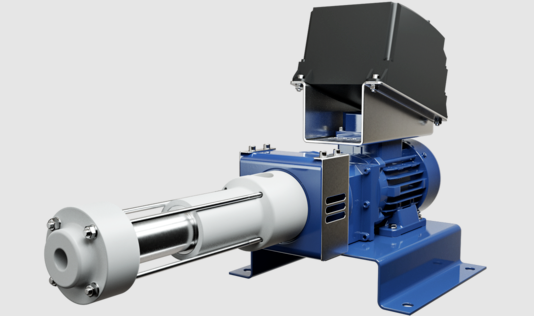

Description of SEEPEX IMP – PROGRAMMABLE METERING PUMP

The SEEPEX IMP is a programmable metering pump designed for precise and reliable dosing in a wide range of applications. Equipped with an intelligent electronic control system, this pump can be configured to meet the specific needs of your process, allowing for accurate dispensing of fluids and chemicals.

Featuring a compact, modular design, the SEEPEX IMP is easy to install and maintain. Its rugged construction ensures long-lasting performance, even in demanding environments. With a variety of materials of construction available, it is suitable for use with a wide range of fluids and chemicals.

Whether you need to deliver small or large volumes of liquid, the SEEPEX IMP programmable metering pump provides the accuracy and flexibility required for precise dosing in any application.

Applications of SEEPEX IMP – PROGRAMMABLE METERING PUMP

The SEEPEX IMP programmable metering pump is suitable for a wide variety of applications in industries such as food and beverage, pharmaceuticals, chemical processing, and water treatment. It can be used for precise dosing of fluids and chemicals in processes such as:

- Adding flavorings, colorings, and preservatives in food and beverage production

- Metering pharmaceutical ingredients in drug manufacturing

- Dispensing cleaning chemicals and additives in chemical processing

- Injecting flocculants and coagulants in water treatment

With its accurate and reliable dosing capabilities, the SEEPEX IMP can help improve process efficiency and reduce waste. Its programmable features allow for precise control over dosing rates, while its modular design makes it easy to integrate into existing systems.

Economical

Reduced costs due to inexpensive rotating unit

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

Durable

High corrosion resistance due to the variety of components made of Hastelloy C or Titanium

Programmable

Downtime is eliminated with Electronic Programming Module (EPM) memory chips when switching drives or changing parameters

Compatible with accessories

Accessories can easily be connected to the drive via control terminals

People Also Ask