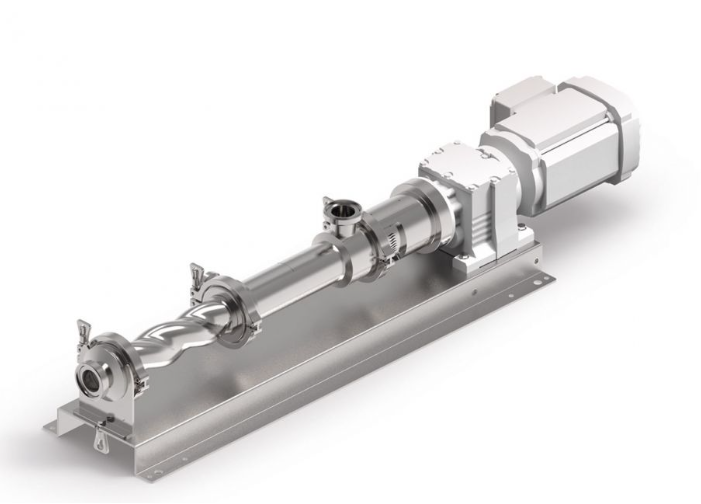

Hygienic progressing cavity pump Type WANGEN MX-S

For demanding hygienic conveying and dosing of aqueous to highly viscous media in the food & beverage-, pharmaceutical, and cosmetics industries. Low-impact delivery of products containing solids. CIP and SIP cleaning is possible, the pump is available as a mobile or stationary unit.

The Description of WANGEN MX-S Hygienic progressing cavity pump

The WANGEN MX-S Hygienic progressing cavity pump is a state-of-the-art pump designed for sanitary and hygienic applications. It features a progressing cavity rotor-stator design, ensuring gentle handling of the pumped product and maintaining product integrity. The pump is constructed with smooth, crevice-free surfaces, and it complies with stringent sanitary standards like FDA and EHEDG guidelines, making it suitable for the food, pharmaceutical, and biotechnology industries. Its compact design and easy-to-maintain features make it a reliable and efficient solution for various hygienic pumping needs.

The Application of WANGEN MX-S Hygienic progressing cavity pump

The WANGEN MX-S Hygienic progressing cavity pump is commonly used in hygienic applications that require handling viscous, shear-sensitive, and delicate materials in the food, beverage, and pharmaceutical industries. Its hygienic design eliminates any dead spaces or crevices where bacteria can accumulate, ensuring that it meets the strict hygiene standards required in these industries. The pump is also easy to clean and maintain, making it an excellent choice for applications where cleanliness and sanitation are critical.

Features of WANGEN MX-S Hygienic progressing cavity pump

- stators in EvenWall® design (uniform elastomer wall thickness)

- various geometries and pump sizes

- external cut surfaces

- wear parts can be replaced quickly via a separation point opposite the product

- robust bearing pedestal for high force transduction

- materials in contact with the product: stainless steel 1.4404

- surfaces of the parts in contact with the product: Ra < 0,8 μm

- modular structure

- materials with FDA certificate on request

- ground, electropolished surfaces

- encapsulated mechanical seal, single or double acting, rinsed by the product

- flexible drive selection (helical geared motors, hydraulic motors)

- CIP (Cleaning in Place)

- discharge flange with self-emptying design

- double bearing arrangement with tapered roller bearings

- service-proven sealing systems

- particularly gentle feeding

- driven by helical geared motor

- fully developed, robust universal joint

- simple, effective cleaning

- easy cleaning thanks to construction with little dead space

People Also Ask