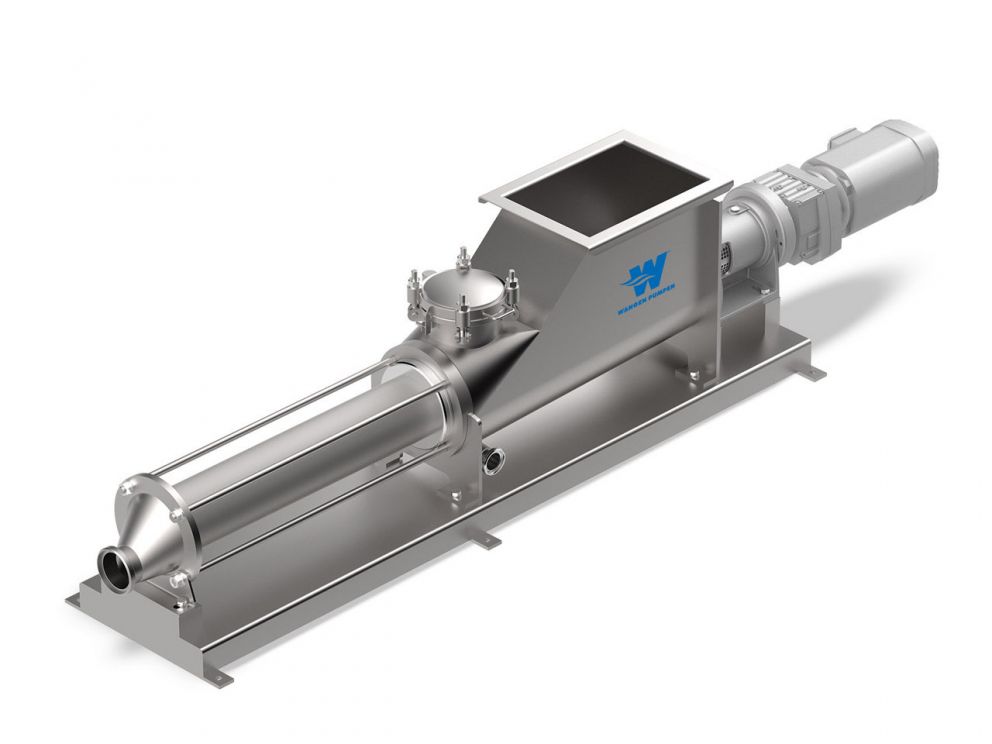

Hygienic hopper feed pump Type KL-RF Hygienic

The hygienic hopper feed pumps of the series WANGEN KL-RF have an inspection cover, a maintenance-free mechanical seal, which is independent of the rotation direction, and the dis-charge nozzle has a self-emptying design. The KL-RF is available with different rotor/stator geometric forms (S-, L- and H shapes).

The Description of WANGEN Type KL-F Hygienic Hygienic Hopper Feed Pump

The WANGEN Type KL-F Hygienic Hopper Feed Pump is a reliable and efficient solution designed for hygienic applications. It is specifically engineered to handle the transfer of viscous and sensitive media in industries such as food processing, pharmaceuticals, and cosmetics. With its hygienic design and smooth operation, this pump ensures optimal product integrity and cleanliness, making it an ideal choice for hygienic pumping requirements.

WANGEN Type KL-F Hygienic Hygienic Hopper Feed Pump Fields of Application

With the hygienic WANGEN KL-RF pump products are pumped in a particularly gentle way and can be optionally heated or cooled. A strength of the KL-RF is its use in plasticising blocks of fat or butter. Upon request, feed aggregates are also possible in special designs, as well as a version with an extension funnel.

- loading

- conveying media

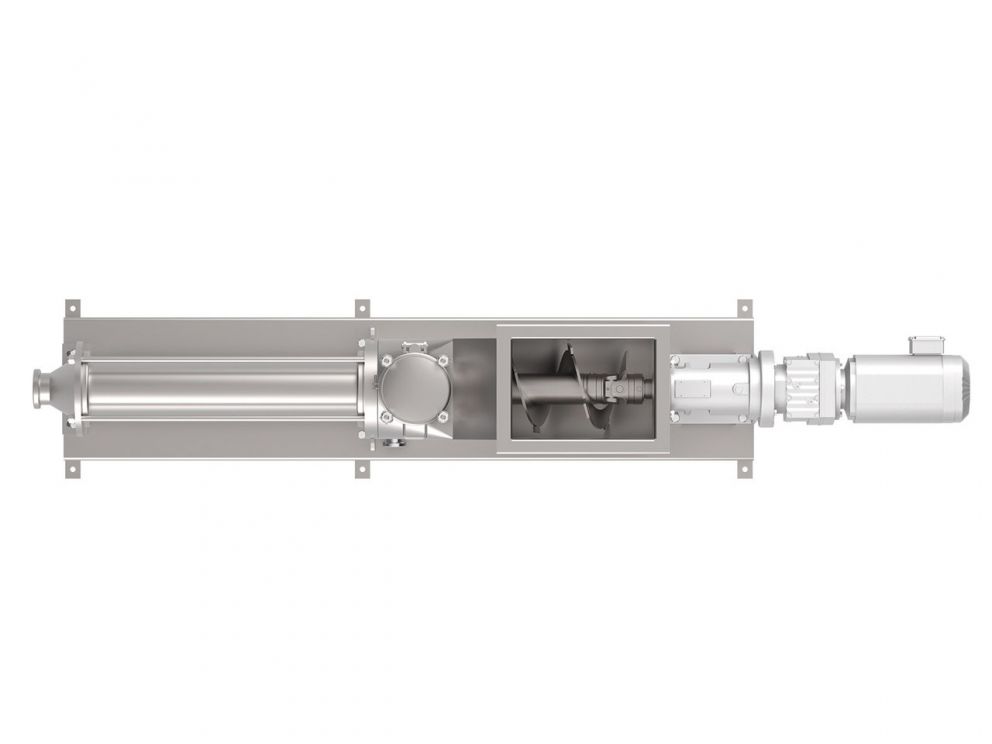

WANGEN Type KL-F Hygienic Hygienic Hopper Feed Pump Technology/Details

- inspection port

- service-proven sealing systems

- maintenance-free mechanical seal independent of the sense of rotation

- various rotor/stator geometries (S, L and H geometry)

- stator with s-cone inlet for optimum filling of the pumping chamber

- easy cleaning thanks to construction with little dead space

- encapsulated mechanical seal, single or double acting, rinsed by the product

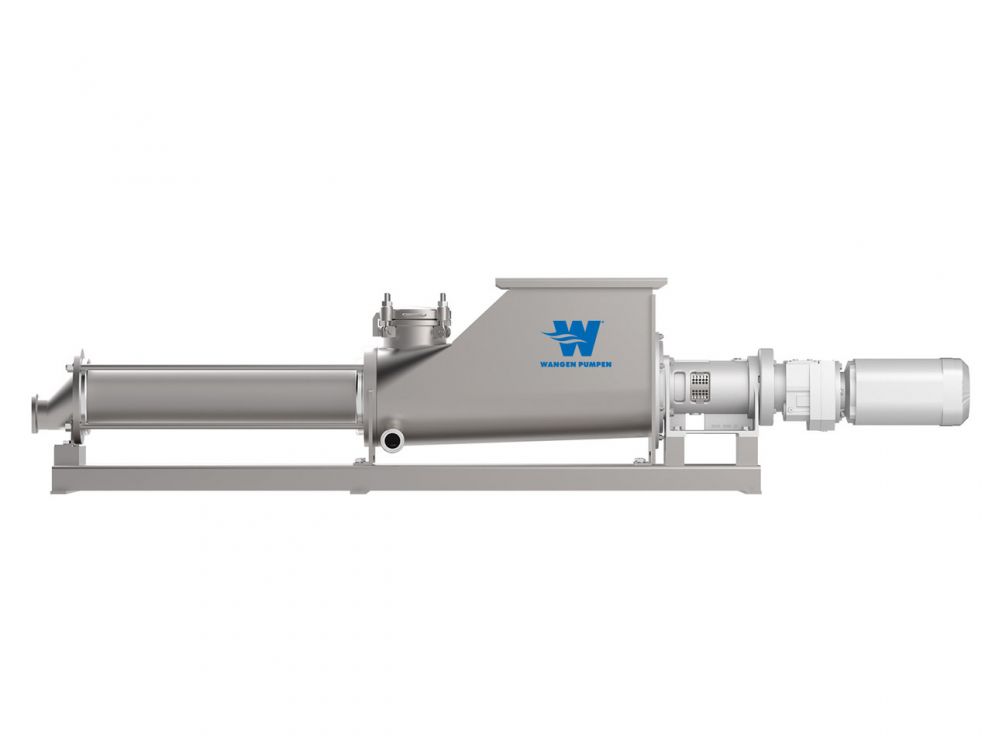

- materials with FDA certificate on request

- special feed unit versions possible

- enlargement possible with add-on funnel

- discharge flange with self-emptying design

- CIP (Cleaning in Place)

- robust bearing pedestal for high force transduction

- robust bearing pedestal with close-coupled drive and self-centering of the drive

- driven by helical geared motor

- specially designed joints

| Output | 4,5 – 22 m³/h |

| Free ball passage | up to 95 mm |

People Also Ask