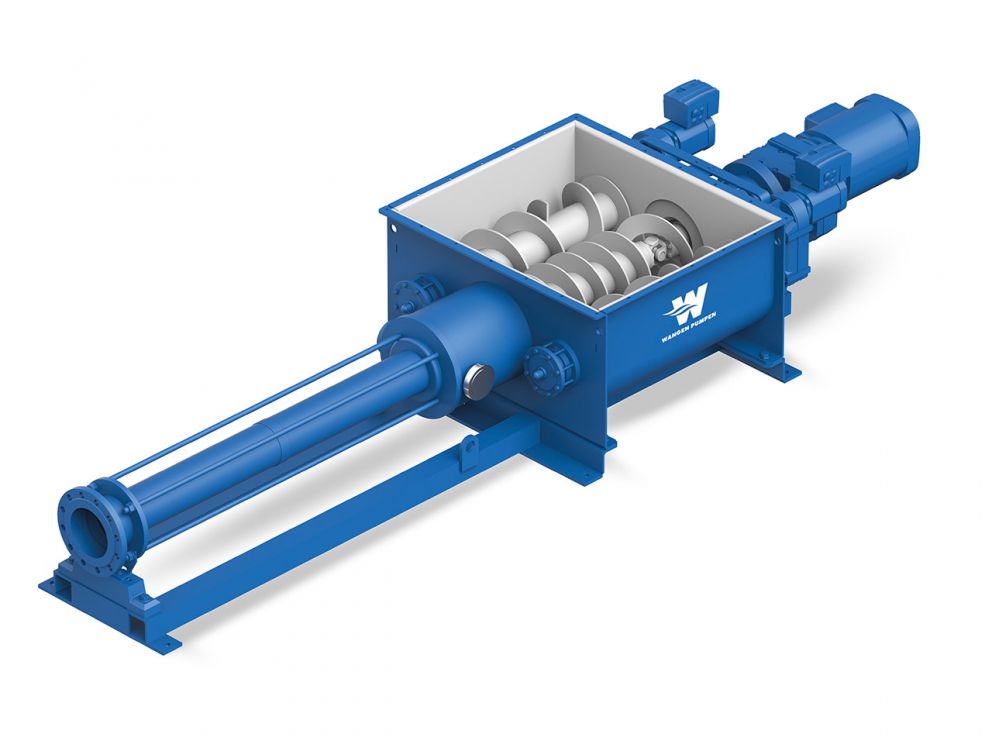

Hopper feed pump Type KL-R Triplex

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small space requirement and large receiving vessel are a result of the low construction and the large volume of the container. The best pump for dewatered sludge in waste water treatment plants. Highest robust design quality, what WANGEN pumps are well known for. Very robust pump, ideal for pumping dewatered sewage sludge and therefore ideally suited for use in the sludge to energy sector. Developed for extra long lifespan.

The Description of Hopper feed pump Type KL-R Triplex

The Hopper feed pump Type KL-R Triplex is a reliable and efficient pump designed for industrial applications. It is specifically designed to handle viscous and abrasive materials with ease. Equipped with a hopper feed system, it is capable of handling materials with a high solids content. The pump is robustly constructed and offers different sizes and configurations to meet various operational requirements. Its user-friendly design allows for easy maintenance and servicing. The Hopper feed pump Type KL-R Triplex is a reliable choice for industries requiring a dependable pumping solution.

The Application of Hopper feed pump Type KL-R Triplex

The WANGEN KL-R Triplex series is able to convey media from chamber filter presses, screen belt presses or decanters to dryers, silos or storage areas, or other feeding jobs.

- from chamber filter presses

- to dryers

- to silos

- to storage areas

- for other feeding jobs

- from screen belt presses

- from decanters

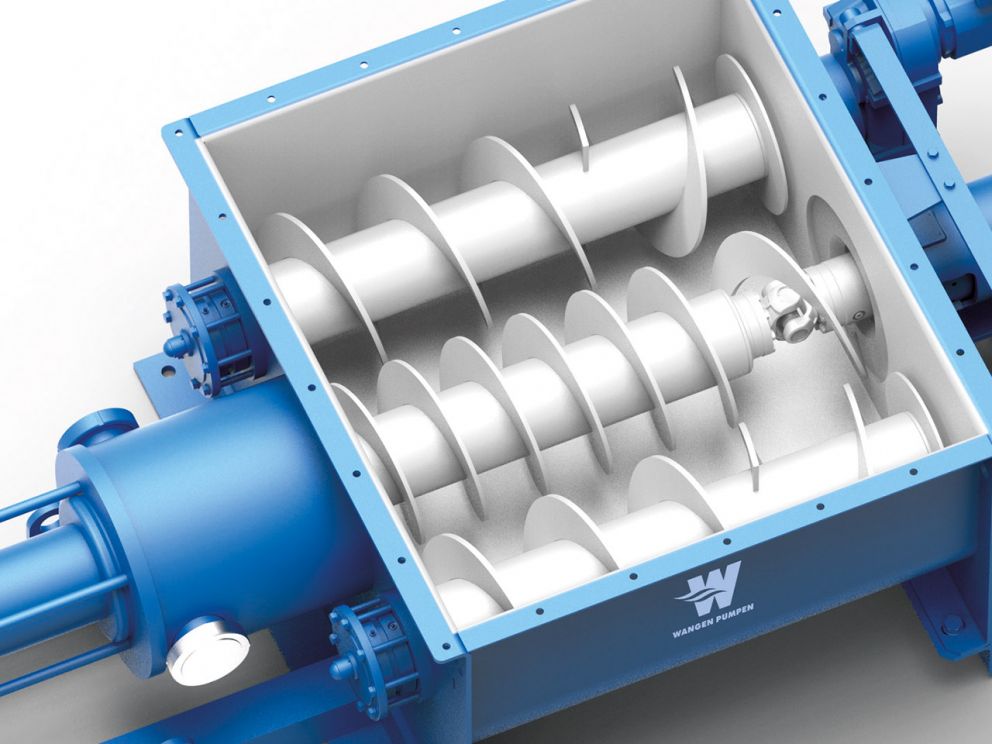

Benefits and Characteristics of Hopper feed pump Type KL-R Triplex

- buffer volume up to 10 m³ possible

- modular design for high flexibility and short downtimes for maintenance and repairs

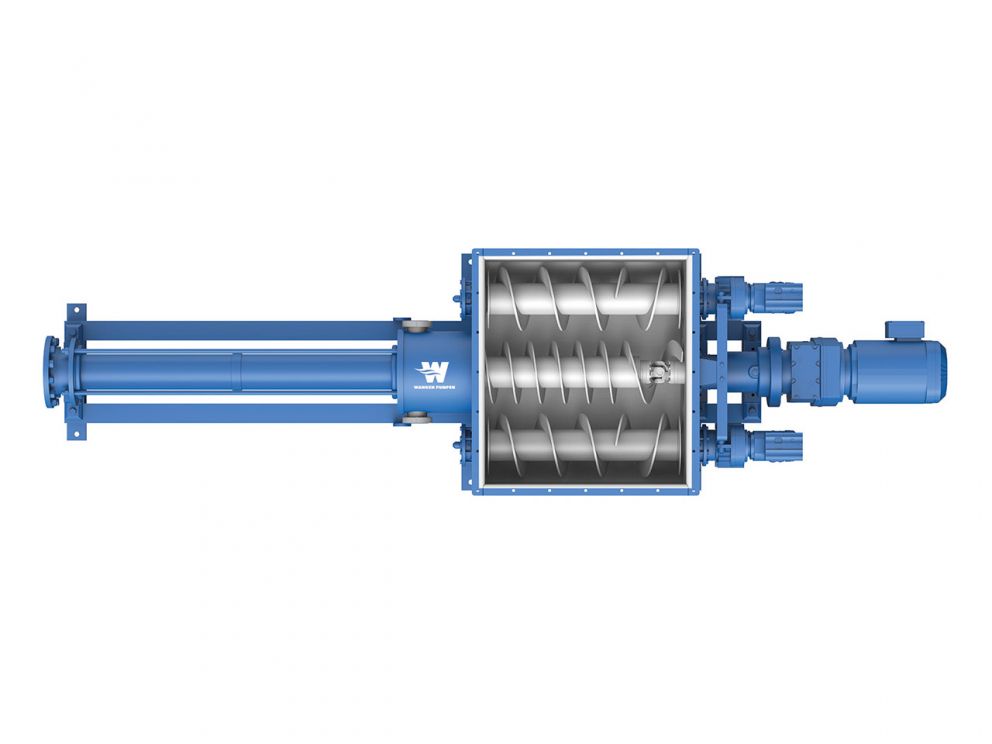

- constant metering because the discontinuous input is compensated by buffer volume in the collecting container

- unattended operation possible

- excellent metering, important for dryer and incinerator operation

- easy to maintain thanks to large cleaning openings

- low-pulsation, continuous conveyance independent of pressure and viscosity

- optimum service life even with difficult media

- high operational reliability

- high pressure performance

- high dosing accuracy, also at low speed

- low Life Cycle Costs

- low construction with large container volume

- little space required, with large collecting container

People Also Ask