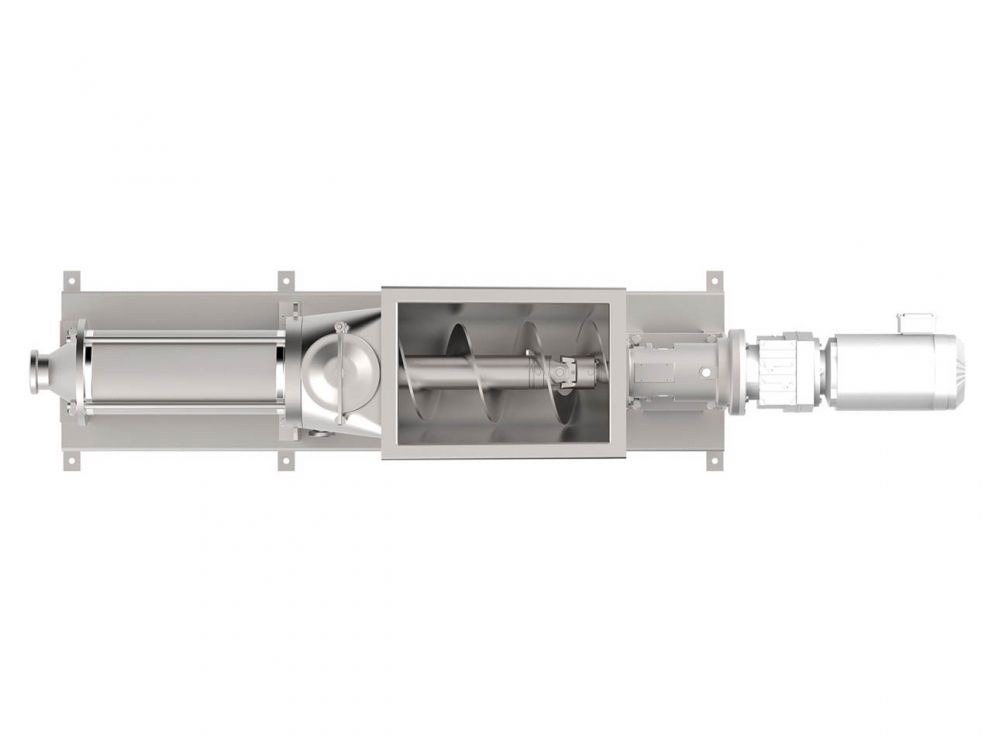

Hygienic hopper feed pump Type KL-RL Hygienic

Pumps of the series KL-RL allow almost pulsation-free pumping of mediums. Depending on the medium to be pumped, the pump can be operated with heating or cooling options, and a variation using an attachable hopper is also possible.

The Description of WANGEN Type KL-RL Hygienic Hygienic Hopper Feed Pump

The WANGEN Type KL-RL Hygienic Hopper Feed Pump is a reliable and efficient pump designed specifically for hygienic applications. It features a hopper feed design, ensuring consistent and controlled product flow. The pump is built with high-quality materials to meet strict hygiene standards and is suitable for use in the food, beverage, and pharmaceutical industries. Its compact size and easy-to-clean design make it a versatile choice for various hygienic pumping needs.

WANGEN Type KL-RL Hygienic Hygienic Hopper Feed Pump Fields of Application

For hygienic and almost pulsation-free conveying of mediums.

The WANGEN Type KL-RL Hygienic Hopper Feed Pump is commonly used in applications requiring hygienic and controlled product transfer. It finds extensive usage in industries such as food and beverage processing, pharmaceutical production, and cosmetics manufacturing. The pump is particularly suitable for handling sensitive and viscous materials, including dairy products, sauces, creams, gels, and pharmaceutical ingredients. Its hygienic design and efficient hopper feed system ensure optimal product integrity and consistent flow, making it an ideal choice for various hygienic pumping applications.

WANGEN Type KL-RL Hygienic Hygienic Hopper Feed Pump Fields Technology/Details

- fully developed, robust universal joint with pre-feeding screw

- maintenance-free mechanical seal independent of the sense of rotation

- various rotor/stator geometries (S, L and H geometry)

- stator with s-cone inlet for optimum filling of the pumping chamber

- stator with s-cone inlet for optimum filling of the pumping chamber

- specially designed joints

- robust cardan joint

- robust bearing pedestal for high force transduction

- inspection port

- materials with FDA certificate on request

- surfaces of the parts in contact with the product: Ra < 0,8 μm

- easy cleaning thanks to construction with little dead space

- encapsulated mechanical seal, single or double acting, rinsed by the product

- enlargement possible with add-on funnel

- flexible drive selection

- discharge flange with self-emptying design

- double, maintenance-free bearing

- CIP (Cleaning in Place)

- driven by helical geared motor

| Output | 13,5 – 65 m³/h |

| Output | up to 95 mm |

People Also Ask