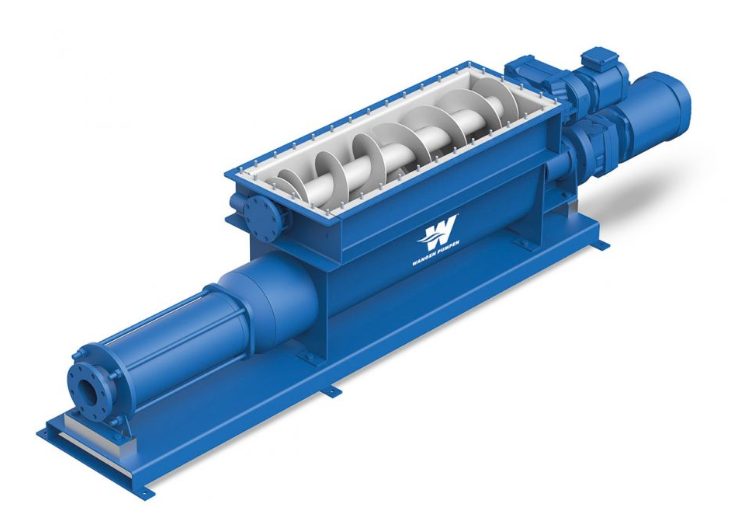

Hopper feed pump Type KL-RUE

Pumps of the WANGEN KL-RÜ series are built according to our proven modular principle. This allows high flexibility, low spare parts inventory, and minimum downtimes for repairs. Other features include: sophisticated and robust cardan joints with screw conveyors, fibers do not get wrapped around the joint and the joint connectors thanks to the effective protection device.

The Description of KL-RUE Hopper Feed Pump

The KL-RUE Hopper Feed Pump is a high-performance and durable pump designed for transferring solid materials. Its robust construction ensures reliability and longevity, making it suitable for demanding industrial applications. With its large hopper and efficient hydraulic system, it enables easy loading and efficient transfer of various types of solids. The adjustable speed and flow control provide flexibility and optimize the transfer process according to specific needs.

The Application of WANGEN KL-RUE Hopper Feed Pump

Pump for conveyance of dewatered sludge with a high solid content.

- conveying media

- feeding

- to storage areas

- to silos

- to dryers

- from screen belt presses

- from decanters

Suitable for the following media

- inorganic slurry

- cement

- lead paste

- sewage sludge

- refinery sludge

- dewatered sewage sludge up to 45 % dry substance

- organic sludge

The Features of WANGEN KL-RUE Hopper Feed Pump

- maintenance-friendly

- robust bearing pedestal with close-coupled drive and self-centering of the drive shaft (optionally with bare shaft)

- various hopper sizes available

- low-pulsation, continuous conveyance independent of pressure and viscosity

- gentle pumping

- modular design for high flexibility and short downtimes for maintenance and repairs

- almost pulsation-free conveyance

- modular design for short downtimes

- consistent modular principle for high flexibility, low stocking of spare parts, short downtimes for maintenance and repairs

- compact construction based on modular principle for high flexibility

- no tangling of fibers around the joint or joint connections

- long service life

- high pressure performance

- high dosing accuracy, also at low speed

- high operational reliability

- good price/performance ratio (standard product group)

- good pumping performance even with abrasive and fibrous materials in the media

- large viscosity range

- constant metering because the discontinuous input is compensated by buffer volume in the collecting container

- low Life Cycle Costs

- unattended operation possible

- excellent metering, important for dryer and incinerator operation

People Also Ask