What is NETZSCH NM021SY02S12B?

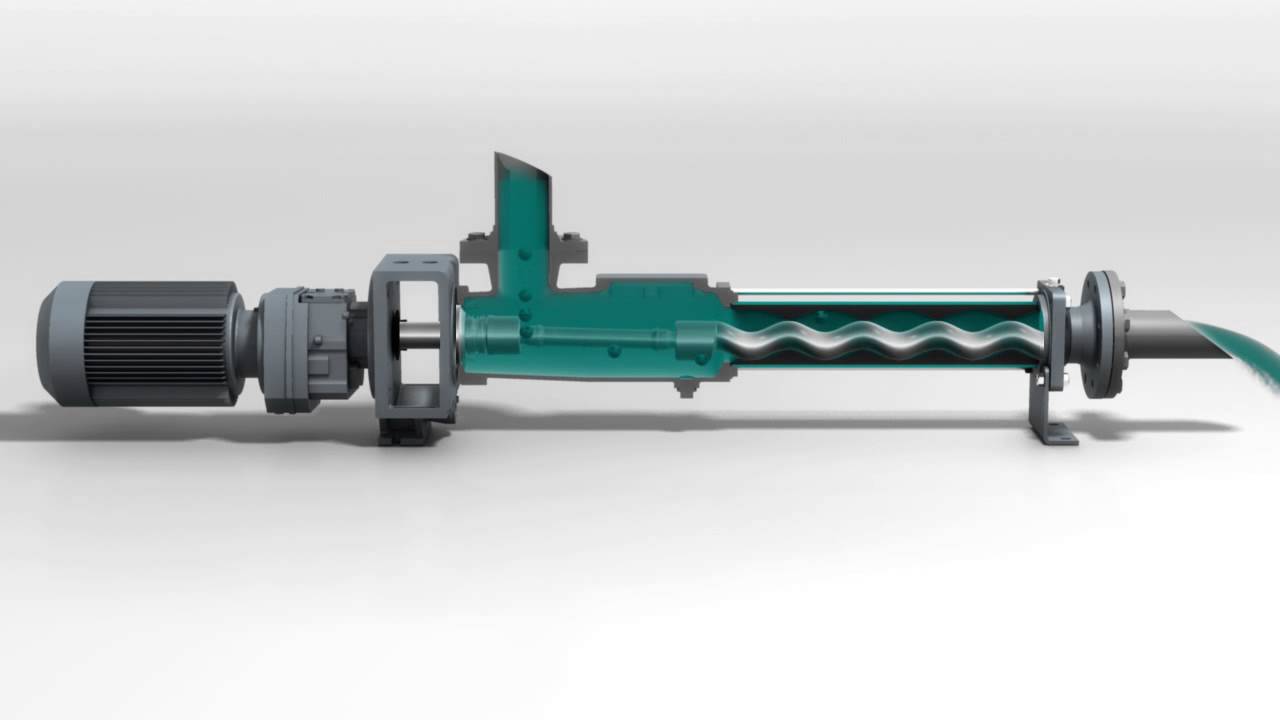

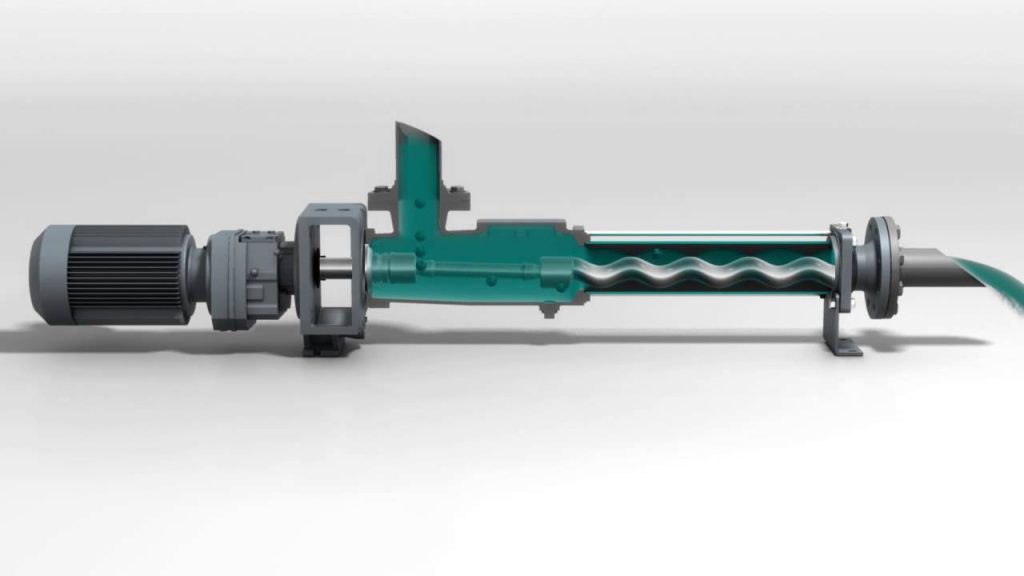

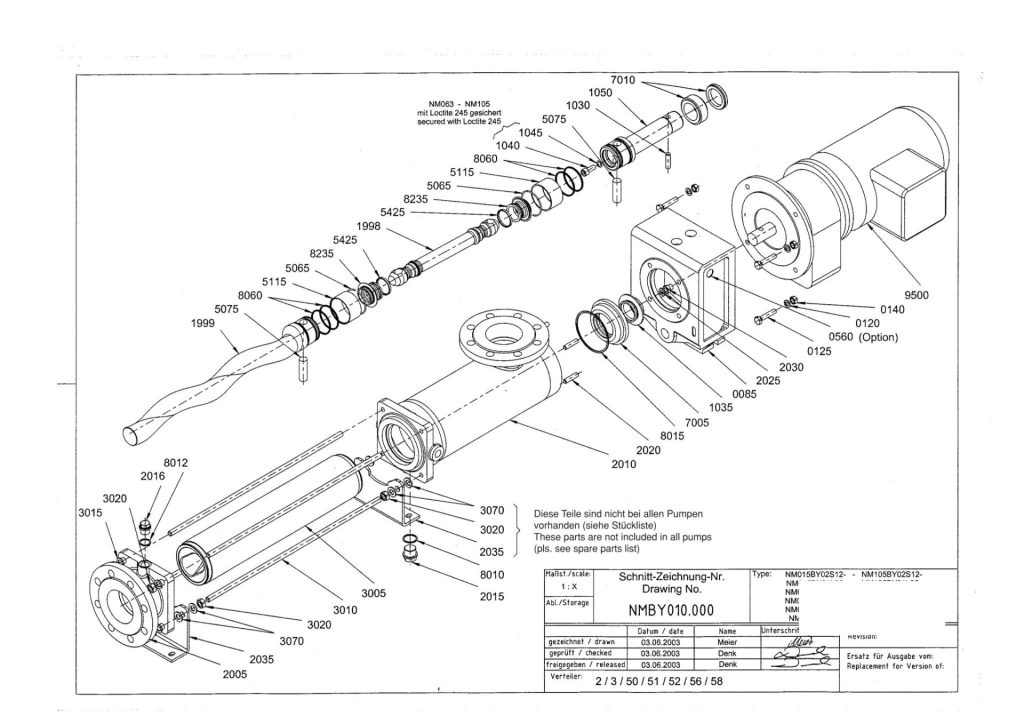

The NEMO Progressing Cavity Pump operates based on a unique positive displacement principle. It consists of a helical rotor and a stator, which are precision-engineered to create a continuous seal and move fluid smoothly through the pump. This design allows for precise control and consistent flow rates, making it ideal for handling a wide range of viscous or abrasive fluids.

The NEMO NM021SY02S12B model is specifically designed for demanding applications that require efficient and reliable pumping. It offers a compact and robust construction, making it suitable for both stationary and mobile installations. The pump is constructed using high-quality materials, ensuring resistance to corrosion and wear, thereby extending its service life.

NETZSCH NM021SY02S12B NEMO PC Pump: Durable, Precise, and Efficient

The Progressing Pump is known for its exceptional durability, corrosion resistance, and ability to operate in challenging environments. It offers reliable and precise fluid control, making it suitable for industries such as chemical processing, oil and gas, and wastewater treatment. With its user-friendly interface and energy-efficient design, this pump is a trusted solution for various pumping requirements.

NETZSCH NM021SY02S12B NEMO Progressing Cavity Pump Excels Across Industries

The NETZSCH NEMO Pump is a versatile solution with a wide range of applications across multiple industries. Its durable construction and ability to handle diverse fluids make it well-suited for demanding tasks in chemical processing, oil and gas exploration and production, wastewater treatment plants, food and beverage manufacturing, pharmaceutical production, and many other industrial sectors. Whether it’s metering and dosing applications, transferring abrasive or shear-sensitive materials, or handling viscous fluids, this pump provides reliable and precise fluid control, ensuring efficient and smooth operations in various challenging environments.

Key features of the NETZSCH NM021SY02S12B NEMO Pump

- Versatile Performance: The NETZSCH Pump can handle fluids with varying viscosities, shear-sensitive materials, and solids up to a certain size, making it suitable for industries such as wastewater treatment, food and beverage, chemical processing, and oil and gas.

- High Efficiency: The precision-engineered design and positive displacement principle result in efficient fluid transfer, reducing energy consumption and operational costs.

- Gentle Handling: The pump’s gentle pumping action minimizes shear forces, ensuring the integrity of delicate or shear-sensitive fluids.

- Easy Maintenance: The modular design allows for quick and easy maintenance, minimizing downtime and maximizing operational efficiency.

- Customization Options: NETZSCH provides various configuration options, allowing customers to tailor the pump to their specific requirements.

Comprehensive Specifications of NETZSCH NM021SY02S12B NEMO Progressing Cavity Pump

| Assortment | Pumps |

| Category | Eccentric screw pumps |

| Stocknumber | STN13154 |

| Manufacturer | NETZSCH Pumps |

| Type | NM021SY02S12B |

| Serial number | 298170 |

| Capacity | 3.000 liter per hour |

People Also Ask