What is NEMO® B.Max® Mixing Pump?

The NEMO B.Max is setting new standards with its maximum mixing and conveying capabilities for biosubstrates. It is the result of continued development work on the NETZSCH NEMO Progressing Cavity Pump with hopper and conveying screw.

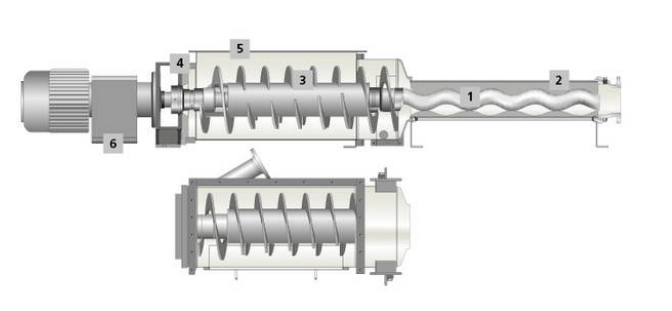

The Description of NEMO® B.Max® Mixing Pump

The pump housing has a large rectangular hopper and removable conical force-feed chamber, as well as a coupling rod with patented, horizontally positioned conveying screw, that guarantee optimal product feeding to the conveying elements. The positioning of the conveying supports on the funnel housing allows for maximum mixing of the substrate.

The NEMO B.Max is particularly well-suited for the following substances

- fermented NAWARO

- liquid manure

- process water

- ground biowaste and food waste

- preprocessed slaughterhouse waste

- cosubstrates

- concentrated substrates

- slop

Advantages of the NEMO B.MaxTM Funnel-Shaped Progressing Cavity Pump

- maximum homogenization of the substrate

- increased gas production

- continuous low-pulsation conveyance independent of pressure and viscosity

- high pressure capability

- robust drive seals

- low investment and operating costs

- high operating safety

- reinforced screw

People Also Ask