Progressive cavity pump spare parts

What are progressive cavity pump spare parts?

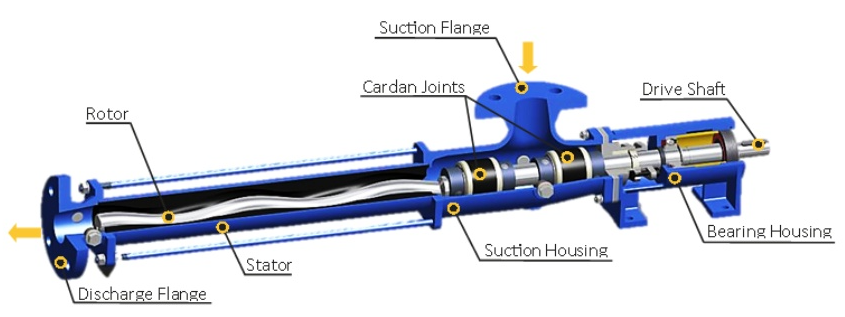

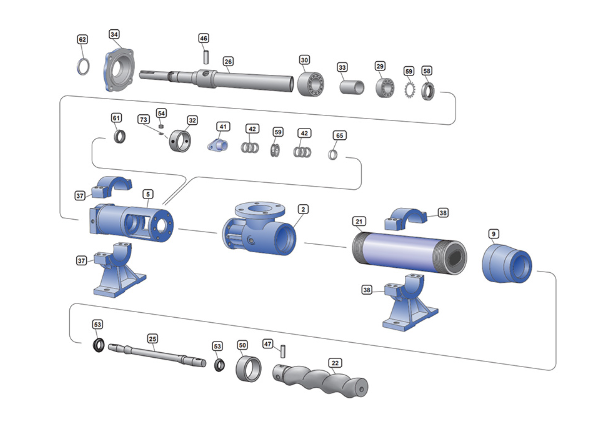

Progressive cavity pump spare parts are components used to maintain and repair progressive cavity pumps, which handle viscous fluids. Common spare parts include stators, rotors, coupling rods, drive shafts, seals, and bearings. Regular maintenance and replacement of these parts is vital for optimal pump performance and longevity.The stator and rotor assembly is the most critical component of a progressive cavity pump, creating a pumping action to move fluid from the inlet to the outlet. Without high quality spare parts, progressive cavity pump efficiency can decrease and breakdowns may occur, leading to costly repairs.

The description of progressive cavity pump spare parts

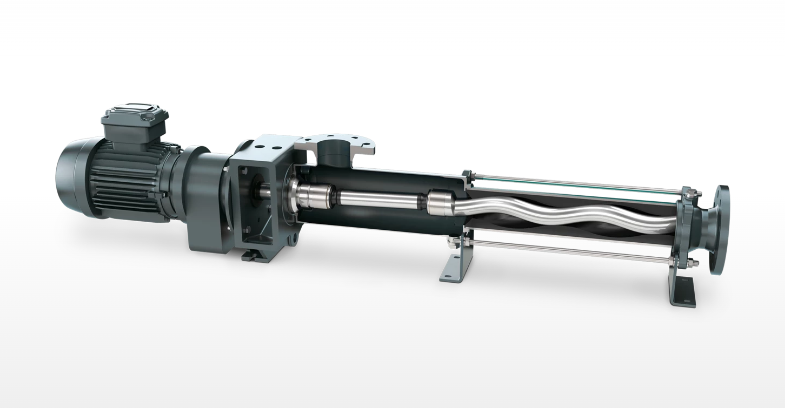

Progressive cavity pumps (PCPs) are positive displacement pumps that are designed to transfer viscous fluids, sludge, and slurries. These pumps consist of a single helical rotor that rotates inside a stator with a double helix cavity. As the rotor turns, it creates a progressive pumping action that moves fluid through the pump at a steady, constant flow rate. To ensure optimal performance, it is important to have high-quality spare parts for these pumps.

The features of progressive cavity pump spare parts

Progressive cavity pump spare parts include various components such as rotors, stators, coupling rods, seals, and bearings. These parts are typically made from materials like rubber, stainless steel, or cast iron depending on the specific application requirements. The rotor and stator are the most crucial PCP components and their design can vary depending on the application. Different types of rotor geometries (e.g. 1L, 2L, 3L, or 4L) and stator elastomers (e.g. nitrile, EPDM, or Viton) can be used to accommodate different fluid viscosities, temperatures, and chemical compositions. High-quality spare parts help to maintain the efficiency and longevity of the pump, which ultimately reduces downtime and maintenance costs.

The application of progressive cavity pump parts

Progressive cavity pump spare parts are essential for maintaining the performance of PCPs across a wide range of industries. They are commonly used in wastewater treatment plants, food processing facilities, chemical processing plants, and oil and gas refineries. In the wastewater industry, PCPs are often used to transfer thick sludge or biosolids from primary clarifiers to digesters or dewatering equipment. In the food industry, they can be used to handle products like tomato paste, peanut butter, or chocolate. In the chemical industry, PCPs are ideal for transferring abrasive or corrosive fluids that may damage other types of pumps. Similarly, in the oil and gas industry, PCPs can be used to transport crude oil, drilling mud, or fracking fluid. Properly maintained pumps can help to reduce operating costs, increase productivity, and improve safety in these industries.frac pump spare parts

In summary, progressive cavity pump spare parts play a critical role in ensuring the efficient operation of these pumps across a range of industries. By using high-quality spare parts, operators can extend the life of the pump and minimize downtime and maintenance costs. The right combination of rotor and stator geometry and elastomer material selection can help optimize the PCP’s performance for a specific application.

The Progressive Cavity Pump Replacement Spare Parts

The Progressive Cavity Pump Stator The stator is one of the main parts of a progressive cavity pump. PC pump stators usually consist of two items: the shell and the lining. Specifically, the shell material normally is metal. For example, carbon steel with painting or stainless steel. And the lining is made of rubbers. According … Read more

Netzsch Pump Parts-Pumpvv

Netzsch Pump Parts: Reliable Components for Progressive Cavity Pumps Netzsch Pump Parts are components designed for use in Netzsch progressive cavity pumps. These parts include stators, rotors, coupling rods, and other essential elements that ensure the efficient and reliable performance of the pump. They are manufactured with high-quality materials and precision engineering to withstand the … Read more

Progressive Cavity Pump Parts

What is the Progressive Cavity Pump Parts? Progressive Cavity Pump Parts are essential components that make up progressive cavity pumps. They are designed for handling fluids with varying viscosities and consistencies, making them widely used in industries such as oil and gas, wastewater treatment, and food processing. These parts are known for their robust construction, … Read more

PCM ECOMOINEAU™C FLOATING STATOR – SMALL FOOD GRADE PROGRESSING CAVITY PUMP

PCM SMALL FOOD GRADE PROGRESSING CAVITY PUMP As one of the most compact progressing cavity pumps available today, the PCM EcoMoineau™C floating stator pump can handle a wide range of fluids with varying viscosities and solids. It provides good a suction lift and can tolerate running dry. It offers low Life Cycle Cost, thanks to simple … Read more

PCM MOINEAU™ API 676 PROGRESSING CAVITY PUMP

PCM MOINEAU™ API 676 PROGRESSING CAVITY PUMP PCM Moineau™A pumps meet all the standard requirements of API 676 positive displacement pumps, and are available in a range of materials including carbon steel, stainless steel, duplex steel and super duplex steel. The PCM’s API 676 pump features a highly modular design that makes installation, operation and … Read more

PCM STANDARD PROGRESSING CAVITY PUMPS

TANDARD PROGRESSING CAVITY PUMPS PCM Oil & Gas surface transfer pumps combine the legendary performance and reliability of PCM progressing cavity pump technology, including a lot of advantages: PCM standard pumps are available in cast iron, carbon steel and stainless steel. People Also Ask

PCM HYFEED HYGIENIC HOPPER PROGRESSING CAVITY PUMPS

Hygienic PCM HyFeed progressive cavity pump The PCM force feeding pumps are adapted to your needs for the transfer of viscous and heterogeneous products. People Also Ask

PCM EASYFEED HOPPER PROGRESSING CAVITY PUMPS

PCM EASYFEED HOPPER PROGRESSING CAVITY PUMPS The growing demand for more concentrated and sophisticated products often implies an increase in the viscosity of the products being transferred. If your product is viscous, pasty, sticky, greasy, thick, or concentrated, PCM provides an appropriate solution for each type of rheology through its range of force feeding progressing … Read more