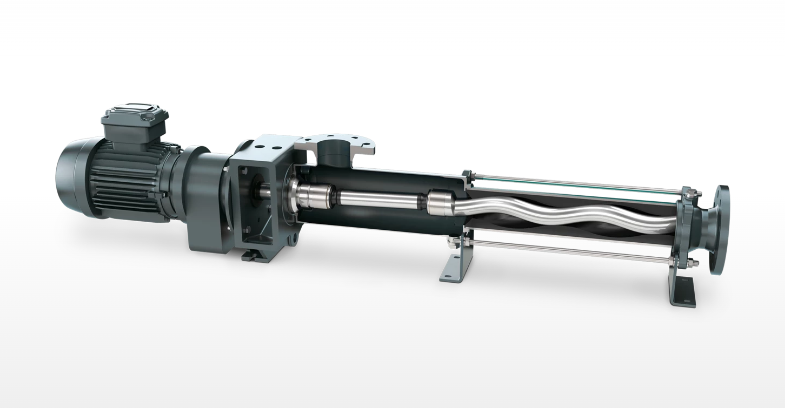

PCM ECOMOINEAU™ C SMALL INDUSTRIAL PROGRESSING CAVITY PUMPS

ECOMOINEAU™ C SMALL INDUSTRIAL PROGRESSING CAVITY PUMPS The EcoMoineau™ C pump is the shortest stainless steel progressing cavity pump available in the market. People Also Ask

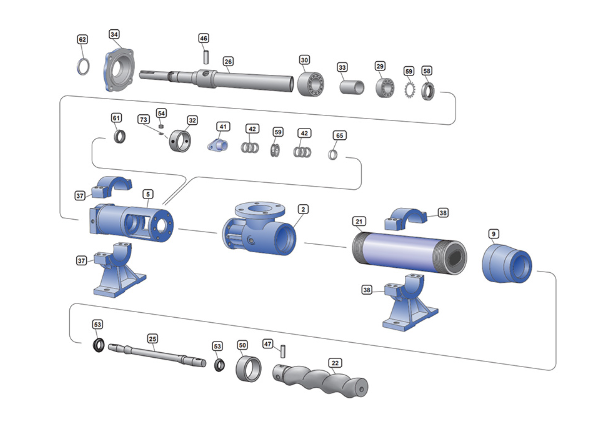

Progressive cavity pump spare parts are components used to maintain and repair progressive cavity pumps, which handle viscous fluids. Common spare parts include stators, rotors, coupling rods, drive shafts, seals, and bearings. Regular maintenance and replacement of these parts is vital for optimal pump performance and longevity.The stator and rotor assembly is the most critical component of a progressive cavity pump, creating a pumping action to move fluid from the inlet to the outlet. Without high quality spare parts, progressive cavity pump efficiency can decrease and breakdowns may occur, leading to costly repairs.

Progressive cavity pumps (PCPs) are positive displacement pumps that are designed to transfer viscous fluids, sludge, and slurries. These pumps consist of a single helical rotor that rotates inside a stator with a double helix cavity. As the rotor turns, it creates a progressive pumping action that moves fluid through the pump at a steady, constant flow rate. To ensure optimal performance, it is important to have high-quality spare parts for these pumps.

Progressive cavity pump spare parts include various components such as rotors, stators, coupling rods, seals, and bearings. These parts are typically made from materials like rubber, stainless steel, or cast iron depending on the specific application requirements. The rotor and stator are the most crucial PCP components and their design can vary depending on the application. Different types of rotor geometries (e.g. 1L, 2L, 3L, or 4L) and stator elastomers (e.g. nitrile, EPDM, or Viton) can be used to accommodate different fluid viscosities, temperatures, and chemical compositions. High-quality spare parts help to maintain the efficiency and longevity of the pump, which ultimately reduces downtime and maintenance costs.

Progressive cavity pump spare parts are essential for maintaining the performance of PCPs across a wide range of industries. They are commonly used in wastewater treatment plants, food processing facilities, chemical processing plants, and oil and gas refineries. In the wastewater industry, PCPs are often used to transfer thick sludge or biosolids from primary clarifiers to digesters or dewatering equipment. In the food industry, they can be used to handle products like tomato paste, peanut butter, or chocolate. In the chemical industry, PCPs are ideal for transferring abrasive or corrosive fluids that may damage other types of pumps. Similarly, in the oil and gas industry, PCPs can be used to transport crude oil, drilling mud, or fracking fluid. Properly maintained pumps can help to reduce operating costs, increase productivity, and improve safety in these industries.frac pump spare parts

In summary, progressive cavity pump spare parts play a critical role in ensuring the efficient operation of these pumps across a range of industries. By using high-quality spare parts, operators can extend the life of the pump and minimize downtime and maintenance costs. The right combination of rotor and stator geometry and elastomer material selection can help optimize the PCP’s performance for a specific application.

ECOMOINEAU™ C SMALL INDUSTRIAL PROGRESSING CAVITY PUMPS The EcoMoineau™ C pump is the shortest stainless steel progressing cavity pump available in the market. People Also Ask

HYCARE™ SANITARY PROGRESSING CAVITY PUMP PCM HyCare™ is the world’s gentlest, most hygienic food sanitary pump. It’s been especially designed for food applications, featuring a patented body design developed using advanced computational fluid dynamics. This progressing cavity pump will treat your ingredients, food safety requirements and budget with the care and respect they deserve. People Also Ask

Dosing/Metering Progressing Cavity Pumps Moyno new line of pumps offering an efficient, reliable and low maintenance solution for applications where low flow, accurate dosing/metering is required. The Moyno dosing/metering pumps provide a smooth pumping action with no pulsation and very low shear. Ideal for either intermittent or continuous duties. People Also Ask

Moyno Tri Phaze The progressing cavity design consists of a single-threaded, external helix (rotor) turning within a double-threaded internal helix (stator). As the rotor turns within the stator, cavities are formed that progress from the suction to the discharge end of the pump. The fluid flows in a spiral path through the pump not far … Read more

SEEPEX – N Range Standard Pumps Product group N pumps come in 2 ranges and are the basis for all SEEPEX progressive cavity pumps. It conveys thin to viscous media, with or without solids, up to approximately 10% dry solids content. People Also Ask

NEMO® BF Wastewater Pump The NEMO® BF Wastewater Pump is a progressive cavity pump designed for handling high-viscosity fluids with solids or fibrous materials without clogging. It features a block-free design and patented FSIP® technology for easy maintenance and cleaning. This pump offers excellent flow rates and pressure capabilities, making it an ideal choice for … Read more

What are progressive cavity pump spare parts? Progressive cavity pump spare parts are components used to maintain and repair progressive cavity pumps, which handle viscous fluids. Common spare parts include stators, rotors, coupling rods, drive shafts, seals, and bearings. Regular maintenance and replacement of these parts is vital for optimal pump performance and longevity.The stator … Read more

What is NEMO® B.Max® Mixing Pump? The NEMO B.Max is setting new standards with its maximum mixing and conveying capabilities for biosubstrates. It is the result of continued development work on the NETZSCH NEMO Progressing Cavity Pump with hopper and conveying screw. People Also Ask

NEMO® BH Sanitary Advanced Pump in Compact Block Design NEMO® BH Sanitary Advanced Pump The NEMO BH hygienic pump in compact block design is used for hygienic applications in the food,pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics. People Also Ask

NEMO BY Progressing Cavity Pump NEMO BY Progressing Cavity Pumps convey a wide array of substances or very precisely meter substances in numerous industrial applications. From low viscosity substances to products barely capable of flowing, with or without solid content, shear-sensitive, sticky or abrasive with the NEMO® BY, even difficult substances are pumped gently and with low pulsation. People Also Ask