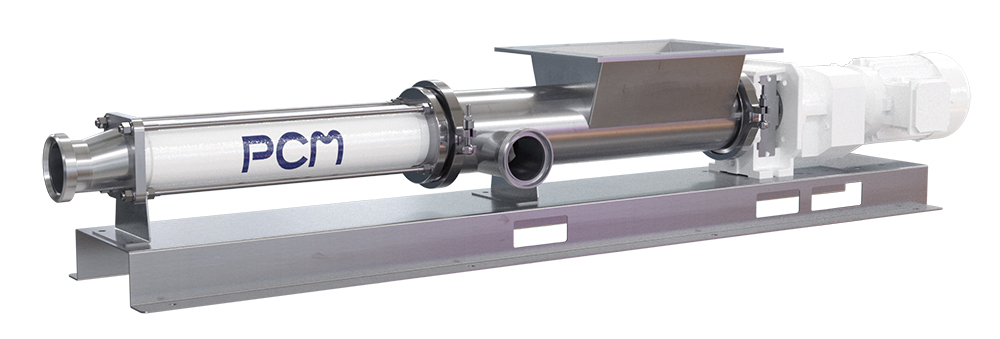

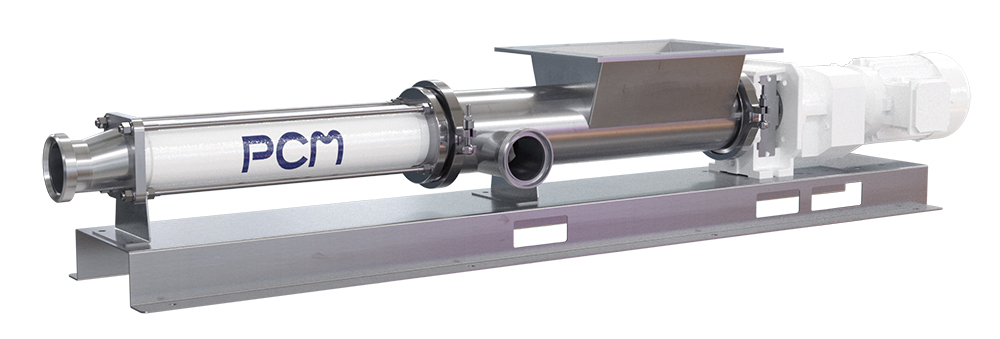

PCM EASYFEED HOPPER PROGRESSING CAVITY PUMPS

The growing demand for more concentrated and sophisticated products often implies an increase in the viscosity of the products being transferred. If your product is viscous, pasty, sticky, greasy, thick, or concentrated, PCM provides an appropriate solution for each type of rheology through its range of force feeding progressing cavity pumps – PCM EASYFEED.

The Description of EASYFEED HOPPER PROGRESSING CAVITY PUMPS

The PCM EasyFeed progressing cavity pump (food grade version) with Moineau™ technology is ideal for transferring highly viscous, heterogeneous with or without particles, pasty or even sticky fluids. This pump is specially adapted to the meat and the fruit & vegetable markets. It has been designed in compliance with food recommendations and requirements to avoid any retention areas and to facilitate cleaning.

The Application of EASYFEED HOPPER PROGRESSING CAVITY PUMPS

The EASYFEED HOPPER PROGRESSING CAVITY PUMPS are positive displacement pumps that are primarily used in industries such as food and beverage, chemical processing, pharmaceuticals, and wastewater treatment. These pumps are designed to handle difficult-to-pump materials such as viscous, abrasive, or shear-sensitive fluids. Their hopper design allows for the effective handling of solids, semi-solids, and highly viscous materials, while the progressing cavity design ensures a gentle flow of the material without causing any damage to it. Overall, these pumps are an ideal solution for applications where traditional pumps would fail due to their inability to handle difficult-to-pump materials.

VERSATILITY AND ROBUSTNESS

- Transfer of various products: heterogeneous or not, fluid or highly viscous, with or without particles, pasty, sticky, fatty…

- For viscosities up to 80 000cp and dryness levels of 30%

- Small pump footprint and and easy to integrate

DESIGN ENSURING FOOD CONTACT SUITABILITY

- Design avoiding any retention areas

- Parts in contact with the product are food grade certified (seals, elastomers, sheaths…)

- 316L stainless steel parts: external shotpeening,internal polishing for a roughness in line with food requirements

SIMPLIFIED MAINTENANCE

- Pump disassembly with clamp collars for immediate access to wear parts and easy clean out of place

- EcoMoineau™ patented rotor coupling system with 3 screws

People Also Ask