The Progressive Cavity Pump Replacement Parts

The replacement spare parts for NETZSCH, MONO, SEEPEX, …

Can highly match with the well-known progressive cavity pumps

What kind of PC pump parts we can supply?

PMV Pump supplies the generic replacement of PC pump spare parts for some well-known PC pump brands like NETZSCH, SEEPEX, MONO, ALLWEILER, etc. The progressive cavity pump parts we supply are accurate and can highly match the mentioned original PC pumps and their universal aftermarket spare parts with equivalent service life.

Certainly, OEM machining service is available. When you have similar pump parts for other brands of progressing cavity pumps to process, we can also manufacture them based on your drawings or samples. Custom pump rotor, stator or other components can be manufactured as requested.

Beside the replacement spare parts for NETZSCH/MONO/SEEPEX pumps. We can also offer bareshaft pumps accordingly that are compatible with your existing pump systems.

The Application of PC Pumps

The progressive cavity pump is just one name of the type of pump. It also has many other different names, such as progressing cavity pump, PC pump, cavity pump, progg cavity pump, screw pump, eccentric screw pump etc.

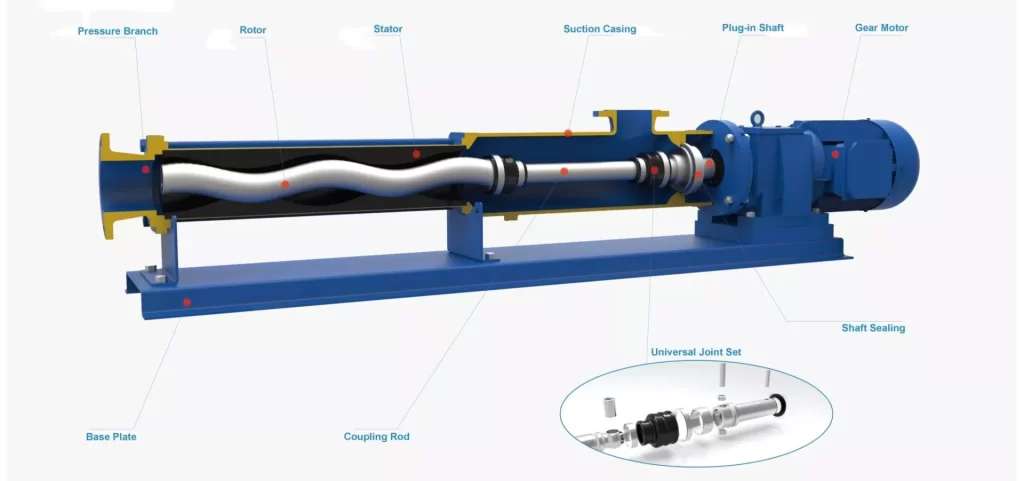

A progressive cavity pump is widely used. Besides the general pumps, there are also food hygiene pumps, dosing pumps, bearing house pump, hopper pumps, bearing house&hopper pumps, bridge breaking pump, vertical pumps, adhesive pump, etc. Below it’s the internal structure of a progressive cavity pump.

We Supply the Universal Replacement Spare Parts for Single Screw Pumps

Progressive cavity pumps usually work in viscous fluid and mediums containing solid particles. In this condition, natural wear is normal and unavoidable. In addition, some abnormal damage will also cause some parts to be replaced. What we supply is the universal replacement of after-market spare parts for the popular progressive cavity pump brands. The brands are mainly NETZSCH, MONO, SEEPEX, ALLWEILER, etc.

For a single screw pump, the wearable and replaceable components are the helical rotor, stator, coupling rod, driving shaft, sealing part and the universal joint set. These universal parts need to be replaced regularly. Generally, we supply all the replaceable pump parts below with a full range of models.

The Progressive Cavity Pump Stator

The stator is one of the main parts of a progressive cavity pump. PC pump stators usually consist of two items: the shell and the lining. Specifically, the shell material normally is metal. For example, carbon steel with painting or stainless steel. And the lining is made of rubbers. According to your pump applications, you can select a type from NBR, HNBR, KFM, EPDM, PTFE, etc.

PMV Pump supplies the replacement parts of Netzsch Stators, SEEPEX Stators, MONO Stators, ALLWEILER Stators, etc. They are equivalent to the original pump stators of NETZSCH PC Pump, SEEPEX PC Pump, MONO PC Pump, etc. and can highly match with the original rotors of these branded progressive cativy pumps.

The Coupling Rods of Cavity Pumps

The coupling rods are metal pump spare parts connecting the rotor and the driving shaft in a progressive cavity pump. In the eccentric screw pumps, the coupling rods are driven by the driving shafts when the motors are running. And then, the coupling rods drive the pump rotors to transmit the mediums.

The Driving Shaft of Progressive Cavity Pump

The drive shaft is a metal pump part that locates between the coupling rod (by the universal joint set) and the driving end, such as a reducer or various drive motors. It’s also a replaceable pump spare part. The drive shafts usually are corrupted by natural wear or media changes in working conditions.

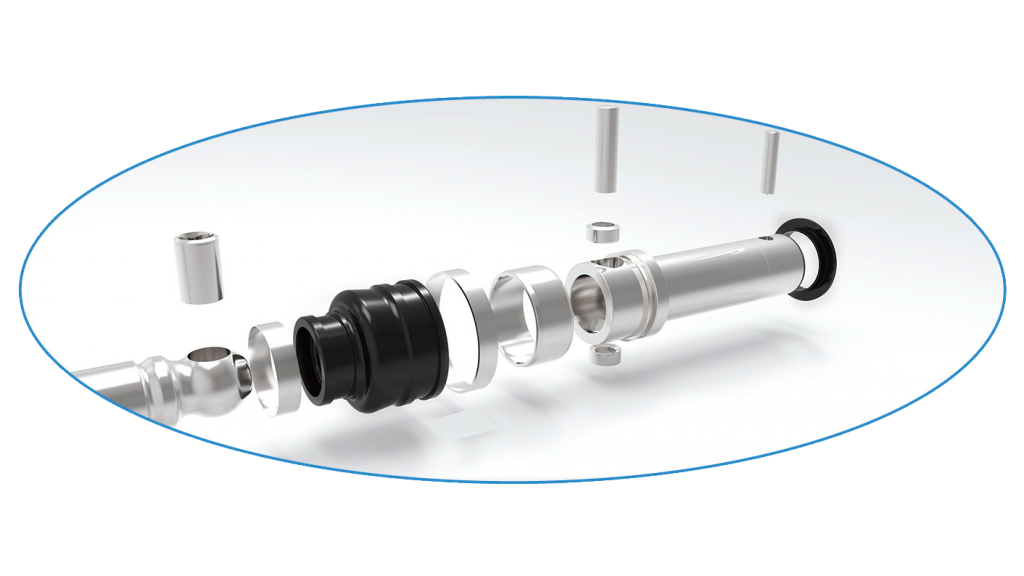

The Coupling Joint Set

The universal joint set is also known as the universal joint assembly. It consists of a group of spare parts and locates at both ends of the coupling rod. Generally, it successfully connects the rotor and the driving shaft to the coupling rod more stably and firmly.

When the pump is running, the rotor makes planetary motion, and its axis is not on the same straight line as the axis of the driving power source. In this way, a special set of components must be designed between the rotor and the drive shaft so that the drive shaft of the power source can drive the rotor to complete such planetary motion. Well, such a group of pump parts are called the universal joint set.

People Also Ask