NEMO® BH Hygienic Pump in Compact Block Design

The NEMO® BH hygienic pump in compact block design is used for hygienic pump applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics .

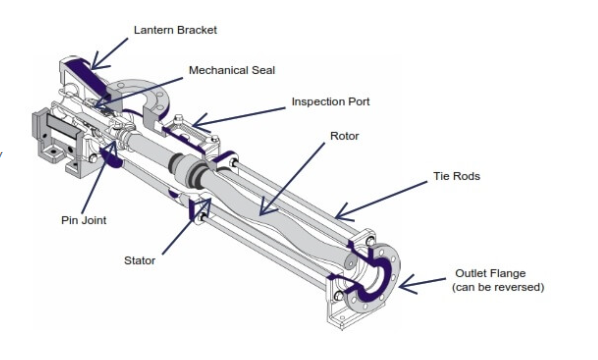

The progressing cavity pump impresses with its continuous, pressure-stable, gentle and low-pulsation conveyance that is independent of pressure and viscosity fluctuations, as well as with dosing in proportion to speed. The hygienic design of the components and machines, as well as the cleanability of the system parts (CIP and SIP capable) are defined in a multitude of regulations. NEMO pumps are designed, manufactured and tested in accordance with FDA (Food and Drug Administration) as well as EU VO 1935/2004.

The compact NEMO® BH pump with a hygienic design is widely used in industries such as food, pharmaceuticals, cosmetics, and chemical/biochemical due to its excellent process features. This type of progressing cavity pump can continuously deliver products in a pressure-stable, gentle, and low-pulsation manner regardless of pressure and viscosity changes. Moreover, it offers proportional dosage based on speed. The machine’s hygienic components and design comply with numerous regulations, and the system parts can be cleaned easily thanks to their CIP and SIP capabilities.

Features of the NEMO® BH Hygienic Pumps

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible conveyance direction

- stator with hopper-shaped entrance for optimal filling of the conveying chamber

NEMO® BH Hygienic Pumps offer you

- gentle product conveyance

- long production cycles with contamination-proof, sterile pump construction

- CIP and SIP capability

- product admission under vacuum conditions up to almost an absolute vacuum

- open, patented hygienic joints for smearing media

- elastomers approved for foodstuffs in accordance to FDA

- horizontal and vertical installation

- easy serviceability

Advantages of the NEMO® BH Hygienic Pump

- foodstuff-suitable shaft seals with compression-proof bolted seal casing enable reversal of the direction of rotation and thereby also of the direction of conveyance, up to the maximum pump pressure

- streamlined, crevice-free housing model prevents sedimentation of the product

- all product-contacting surfaces are polished to prevent build-up of the medium and facilitate cleaning

- the pump housing and stator can be optionally heated

| Fluid | for chemicals, for food products |

| Operation | with electric motor |

| Priming | self-priming |

| Technology | progressive cavity |

| Mobility | stationary, mobile |

| Domain | for the chemical industry, for the food industry, for the pharmaceutical industry, for the cosmetics industry, for hygienic applications |

| Applications | transfer, metering, filling, transport, conveying |

| Fluid specification | for solids-laden fluids, for low-viscosity fluids, for medium-viscosity products, for high-viscosity fluids |

| Other characteristics | compact, close-coupled |

| Flow | Min.: 0 m³/h (0 ft³/h) Max.: 120 m³/h (4,237.76001 ft³/h) |

| Pressure | Min.: 0 bar (0 psi) Max.: 24 bar (348.091 psi) |

People Also Ask