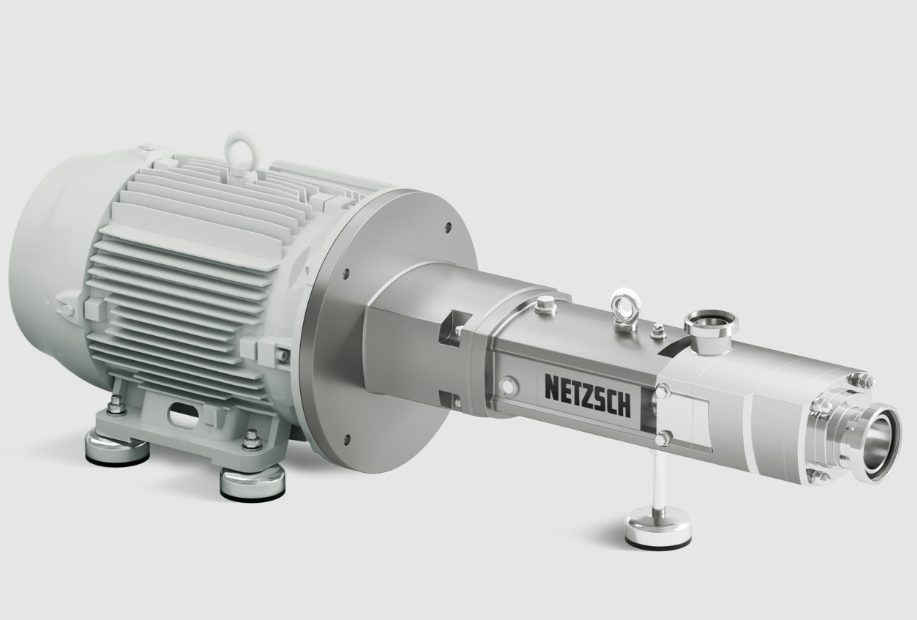

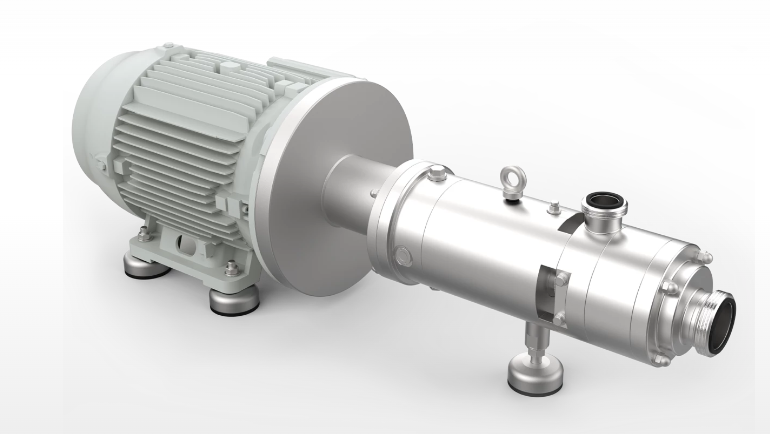

NETZSCH NOTOS® 2NSH Screw Pump

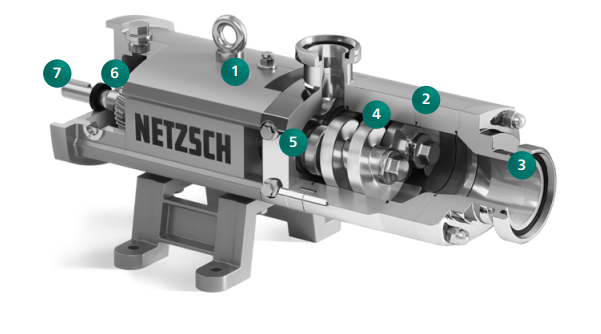

NETZSCH NOTOS is made of AISI 316L stainless steel and polished according to international standards, making it

easy to clean (CIP) and to sterilize (SIP). As there is no contact between the rotating parts, the pump speed

can be increased. Therefore cleaning can be carried out without the need for an auxiliary system.

Broad range of applications

- Food industry: dairy products,delicacies, ketchup, sauces,confectionery and baby food

- Beverage industry: fruit juices,syrups, concentrates, breweries

- Cosmetic and pharmaceutical industry: creams, active substances, ingredients

- Chemical industry: adhesives,solvents, paints, varnishes andplastics

Screw Pump General Characteristics

NOTOS® 2NSH meets the high requirements of food, beverage,chemical, pharmaceutical and cometic industries:

- Metal parts made of stainless steel

- High suction capability (low NPSHr)

- No contact between the rotating parts

- Reversible flow

- Low pulsation

- No dead spaces

- Smooth feeding of the pumped media

NETZSCH NOTOS® 2NSH Screw Pump Parmeters List

| Parameters | Unit | 2NSH-/16L1E | 2NSH-/16L2E | 2NSH-/16L3E |

| Operating rotational speed | RPM | up to 1.800 | up to 1.800 | up to 1.800 |

| Cleaning rotational speed | RPM | up to 3.600 | up to 3.600 | up to 3.600 |

| Standard flow differential pressure | Bar | maximum 16 bar ¹ | maximum 16 bar ¹ | maximum 16 bar ¹ |

| Reverse flow differential pressure | Bar | maximum 12 bar ¹ | maximum 12 bar ¹ | maximum 12 bar ¹ |

| Viscosity | cP | from 1 to 1,000,000 ² | from 1 to 1,000,000 ² | from 1 to 1,000,000 ² |

| Temperature of the pumped fluid | ºC | from -20 to 130 3 | from -20 to 130 3 | from -20 to 130 3 |

| Size of the discharge nozzle | In. | 1,5″ up to 2,0″ | 2″ up to 3.0″ | 2.5″ up to 4″ |

| Size of the suction nozzle | In. | 1,5″ up to 2,5″ | 2″ up to 4.0″ | 3″ up to 4″ |

| Installation position | — | Horizontal | Horizonta | Horizontal |

| Maximum flow rate | m³/h | up to 11 m³/h | up to 25 m³/h | up to 65 m³/h |

| Material of wetted parts | — | AISI 316L (standard) | AISI 316L (standard) | AISI 316L (standard) |

People Also Ask