BIG ON MAKING THINGS SMALL

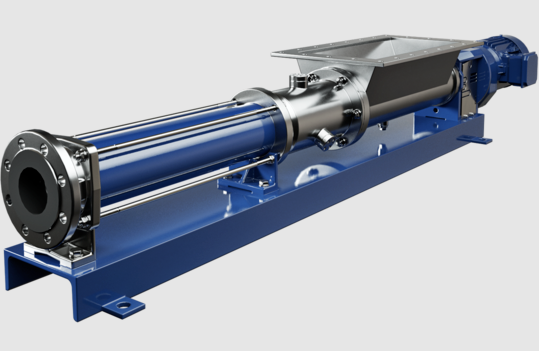

Externally extended compression casing fitted with internal cutting elements: the BTM hopper pump from SEEPEX can be used to prepare e.g. fruit and vegetables for smooth onward transportation. The integrated cutting unit and additional blades in the screw conveyor shred a wide range of solids, thus making them flowable.

Description of SEEPEX BTM – WITH MACERATING SYSTEM

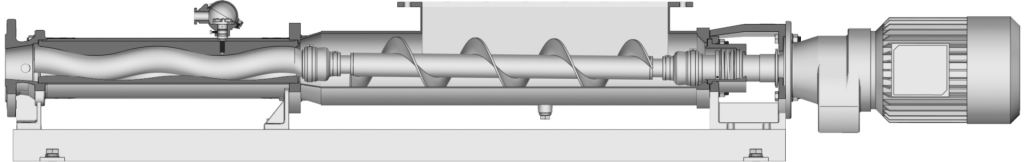

SEEPEX BTM is a device that is designed to transfer and macerate waste water, particularly in applications where the sewage needs to be pumped vertically or over a long distance. The SEEPEX BTM combines a macerator with a progressive cavity pump, which enables it to effectively macerate solid material and pump viscous media.

The macerator component of the SEEPEX BTM uses a cutting mechanism to grind up solid materials such as toilet paper, wipes, and other debris that can cause blockages in pipes and pumps. This maceration process helps prevent clogs and reduces maintenance requirements for downstream equipment.

The progressive cavity pumps component of the SEEPEX BTM uses a helical rotor and stator to move the macerated waste water through the system. This type of pump is well-suited for pumping thick, viscous fluids and can generate high volume and pressure.

Overall, the SEEPEX BTM with its macerating system is an efficient and reliable solution for transferring and processing waste water with solids, especially in situations where traditional pumps may not suffice.

Enhancing Hygiene Standards with SEEPEX BTCS Hopper Pumps

The SEEPEX BTM is commonly used for transferring and macerating waste water that contains solids, in applications such as sewage treatment plants, industrial wastewater treatment facilities, and residential and commercial buildings. It is particularly useful for pumping viscous media vertically or over long distances, and can effectively reduce blockages and maintenance requirements for downstream equipment.

Effective

Particularly fine maceration of large pieces by two integrated blade systems – making even the coarsest chunks flowable

Oxidation-free

o oxidation when installed in a closed system – the food therefore retains its quality and odors are minimized

Optimum product conveyance

Conveyance of the optimal flow rate to the downstream rotating unit by compressing the medium in the compression zone

Adaptable

Length of rectangular intake hopper adjustable to upstream components

Variable

Available in block design with directly flanged-on drive system, or as a variant with free bare shaft and plug connection

People Also Ask