Parameters

- Brand: SEEPEX

- Pressure: 0.6Mpa

- Pump shaft position: horizontal

- Impeller suction mode: single suction

- Drive mode: electric

- Performance: no leakage

- Transport medium: sewage pump, impurity pump

- Flow rate: 130m3/h

- Lift: 60m

- Working pressure: 0.4MPa

- Weight: 300kg

- Voltage: 380V

- Model: BN130-6L

- Application: sewage pump

- Material: cast steel

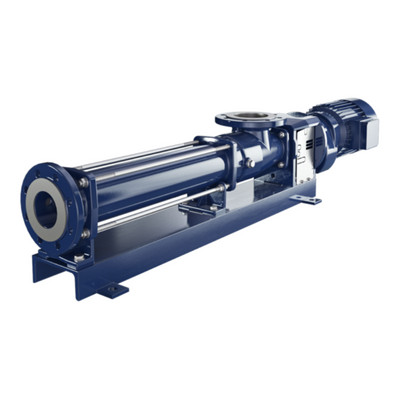

Introduction to BN130-6L

The rotor is made of wear-resistant materials to ensure good performance under high pressure and high temperature conditions. The spiral shape of the rotor can effectively push the fluid, and through its unique geometry, the shear force on the fluid during the conveying process is significantly reduced. This feature is particularly important for some sensitive fluids (such as food and medicine). The stator is made of elastic material, which provides excellent sealing effect, prevents leakage, and enhances the overall efficiency of the pump.

The performance of BN130-6L is not only reflected in its efficient fluid conveying ability, but also in its flexible operation settings. Users can easily adjust the pump speed according to actual needs to achieve different flow rates and pressures. This flexibility allows the BN130-6L to adapt to various process conditions and improve production efficiency. The maintenance of the Seepex BN130-6L is also relatively simple. The replacement process of the rotor and stator is very convenient, and users only need to check regularly to ensure that the pump operates stably for a long time.

The Seepex BN130-6L pump is widely used in many industries, including chemicals, food processing, pharmaceuticals, and environmental engineering. In the fields of sewage treatment and slurry transportation, the BN130-6L has won the favor of users with its outstanding performance.