Parameters

| Brand::SEEPEX | Performance:Wear-resistant | Flow rate:0.5-5(m3/h) |

| Drive mode:Electric | Weight:50kg | Number of impellers:Single stage |

| Power:1.5kW | Lift:0m | Pump shaft position:Horizontal |

| Speed:54-380(rpm) | Suction port:DN65(mm) | Discharge port:DN50(mm) |

| Output flow rate:200 | Voltage:380V | Efficiency:98% |

| Material:Stainless steel | Shaft power:1.5 | Model:BN10-6L |

Advantages of BN10-6l

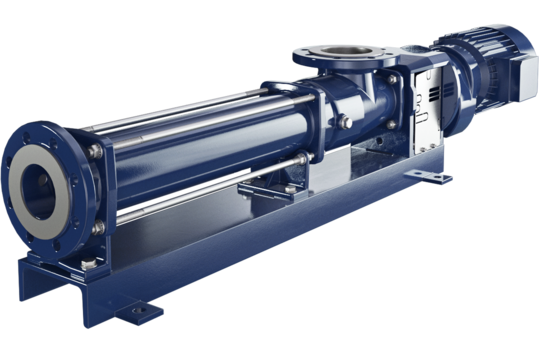

seepex BN10-6 pump adopts advanced engineering design to ensure efficient fluid delivery, whether it is high viscosity liquid, corrosive media or liquid containing solid particles, it can be stably delivered.

Its core components include rotor and stator. The rotor is a spiral metal part installed inside the pump body and rotates with the pump shaft. The stator is a special rubber product with a spiral inner wall, which cooperates with the rotor to form a closed conveying chamber.

The structure is sturdy and durable, and the precision manufacturing of each component ensures long-term stable operation and reduces maintenance costs and downtime. The seepex BN10-6 pump is suitable for a variety of industrial scenarios, such as chemical, food processing, sewage treatment and other fields, providing efficient fluid delivery solutions for different industries.

The seepex BN10-6 liquid pump achieves excellent performance and reliability by optimizing the design of the rotor and stator, and is suitable for handling various industrial liquids. Its high-quality construction and precision processing ensure the stable operation and long-term use of the pump.