Parameters

| Drive mode:Electric | Suction diameter:DN80 |

| Performance:Wear-resistant | Discharge diameter:DN80 |

| Number of impellers:Single stage | Power:4kW |

| Flow rate:4.5-22.4 | Material:Cast iron |

| Head:60 | Model:BN17-6 |

| Speed:276 | Shaft power:4 |

| Weight:60 |

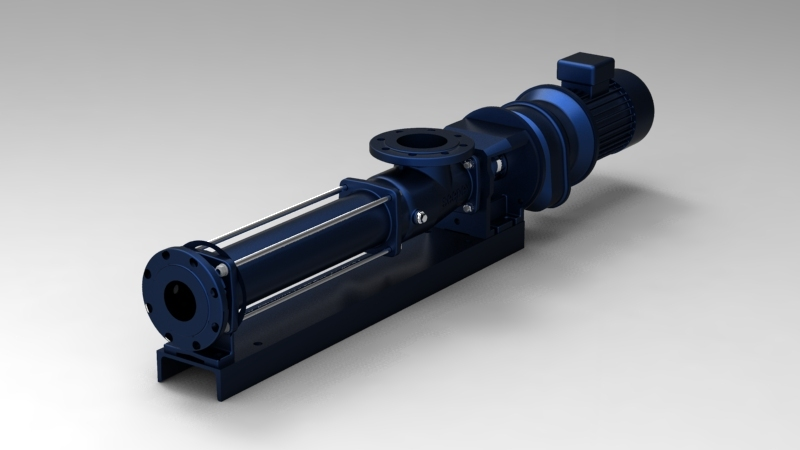

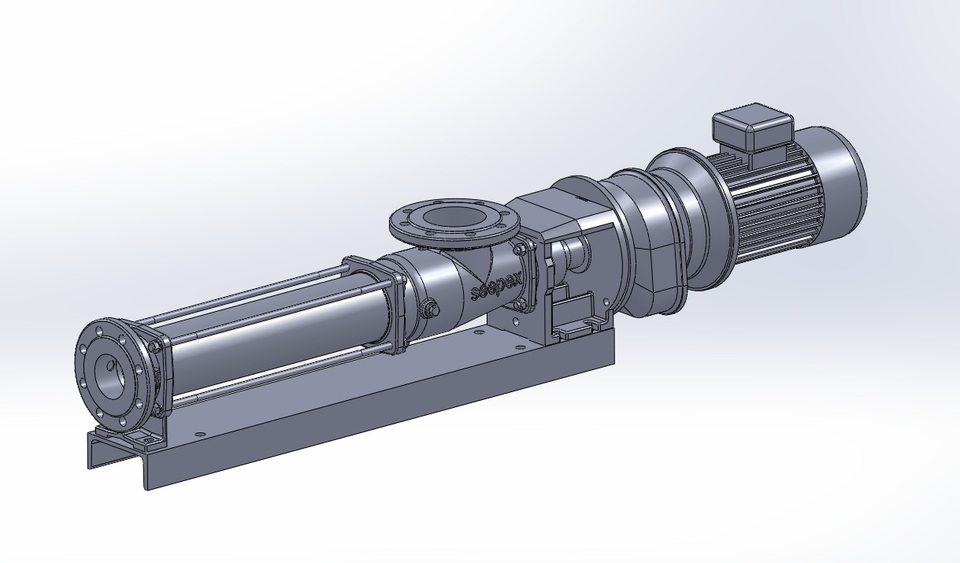

BN17-6 introduction

The rotor is the rotating part of the pump, and its surface is spiral, which can push the liquid to flow along the axial direction of the pump body. The stator is the stationary part of the pump, and it also has a spiral channel inside, which matches the shape of the rotor.

When the rotor rotates inside the stator, positive pressure is generated, which transports the liquid from the inlet to the outlet. It can transport viscous media containing solid particles and has a wide range of applications.

Since there is a sealed space between the rotor and the stator, the liquid will not flow back to the inlet even when the pump stops running, which greatly improves the safety of the system.

The self-priming ability of seepex BN17-6 is excellent, and it can easily cope with negative pressure or siphon conditions, greatly enhancing the flexibility of use. The design and manufacturing of seepex BN17-6 also reflect the excellent craftsmanship level.

Its rotor and stator use precise CNC machining technology to ensure the high consistency of parts and strict dimensional tolerances. At the same time, the pump body structure has been optimized and has good corrosion resistance and wear resistance, which greatly extends the service life.