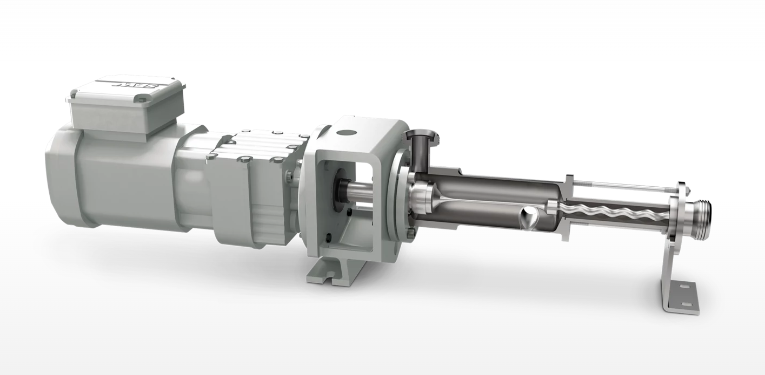

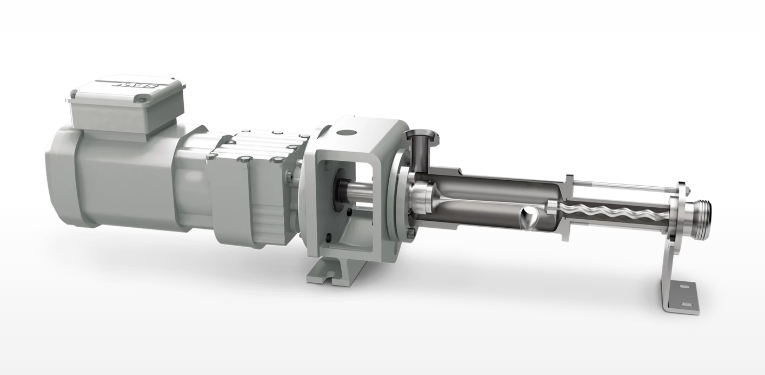

NEMO® BH Mini Hygienic Pump

The NEMO® BH Mini hygienic pump ensures continuous and low-pulsation conveying and is used for hygienic applications and optimum cleaning, especially in the food, pharmaceutical, cosmetics, chemical and biochemical industries.

Description of EMO® BH Mini Hygienic Pump

The NEMO Mini BH Hygienic Progressing Cavity Pump is employed above all in the foodstuff, pharmaceutical, cosmetic and chemical/biochemical industries for hygienic applications. It is ideal in these settings due in part to its continuous,pressure-stable, smooth and low-pulsation conveyance and in part to its capability of dosing in proportion to speed. Inthe block construction with flanged drive, the NEMO Mini BH is particularly compact and economical.Many different regulatory bodies have set specifications for a hygienically correct configuration of components and machines, as well as for component cleanability.NEMO PUMPS are designed, produced and inspected in accordance with the regulations of the EHEDG (European Hygienic Equipment Design Group) and the QHD (Qualified Hygienic Design). The materials used are approved by the FDA (Food and Drug Administration) and the BfR (German Federal Institute for Risk Assessment). In addition, NEMO Hygienic and Aseptic Eccentric Screw Pumps meet the specifications of the United States’ 3-A Sanitary Standards and are GOST-R certified (a Russian certificate of conformity).

Features of the EMO® BH Mini Hygienic Pump

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible conveyance direction

stator with funnel-shaped entrance for optimal filling of the conveying chamber

- gentle product conveyance

- long production cycles with contamination-proof, sterile pump construction

- CIP and SIP capability

- product admission under vacuum conditions up to almost an absolute vacuum

- open, patented hygienic joints for smearing media

- elastomers approved for foodstuffs in accordance with FDA and BfR

- horizontal and vertical

Applications of EMO® BH Mini Hygienic Pump

- Metering of additives: The EMO® BH Mini Hygienic Pump can be used to meter small amounts of additives into a process stream with high accuracy. This is important in the food and beverage industry where precise dosing of ingredients is critical for product quality.

- Transfer of sensitive fluids: Since the EMO® BH Mini Hygienic Pump is made of stainless steel and other non-reactive materials, it is ideal for transferring sensitive fluids such as pharmaceutical products, cosmetics, and biotech fluids that require a hygienic environment.

- CIP (clean-in-place) systems: The EMO® BH Mini Hygienic Pump is designed to be easily disassembled and cleaned using standard CIP techniques, making it an ideal choice for use in CIP systems.

- Sampling: The EMO® BH Mini Hygienic Pump can also be used for taking small samples from a process stream for quality control purposes.

People Also Ask