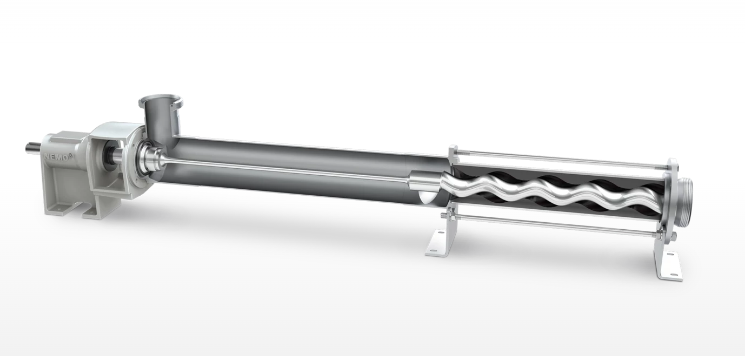

NETZSCH NEMO® SH Plus Hygienic Pump With Hygienic Bearing Houses

The NEMO® SH Plus hygienic pump is employed for hygienic applications and optimal cleaning (CIP/SIP Process) in the food, pharmaceutical, cosmetic and chemical/biochemical industries in order to provide continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed.

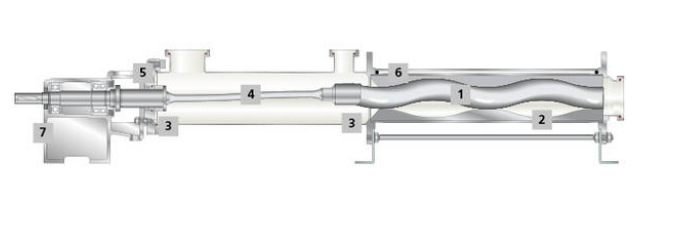

Description of the Design and Compliance Standards of NEMO® Progressive Cavity Pumps

The design with bearing block and free shaft end allows universal use of all types of drives. The progressing cavity pump is particularly suitable for shear-sensitive, low to highly viscous, lubricating, non-lubricating, solid-loaden, solids-free, thixotropic, dilatant, abrasive or adhesive media. The hygienic design of the components and machines, as well as the cleanability of the system parts (CIP and SIP capable) are defined in a multitude of regulations. NEMO® pumps are designed, manufactured and tested in accordance with FDA (Food and Drug Administration) and EU-VO 1935/2004 (EU regulation on food contact materials). Furthermore, NEMO® hygienic and aseptic progressive cavity pumps comply with the regulations of the 3-A Sanitary Standard of the USA and are GOST-R (certificate of conformity for Russia).

Features of the NEMO® SH Plus Hygienic Pumps

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible conveyance direction

- stator with funnel-shaped entrance for optimal filling of the conveying chamber

NEMO® SH Plus Hygienic Pumps offer you

- flexible rod design for uncompromising hygiene and long service life

- gentle product conveyance

- long production cycles with contamination-proof, sterile pump construction

- CIP and SIP capability

- product admission under vacuum conditions up to almost an absolute vacuum

- open, patented hygienic joints for smearing media

- elastomers approved for foodstuffs in accordance with FDA and BfR

- horizontal and vertical in

Application of NETZSCH NEMO® SH Plus Hygienic Pump in the Food Industry

In the food industry, maintaining high levels of hygiene is critical to prevent contamination and ensure product quality. The NETZSCH NEMO® SH Plus Hygienic Pump is specifically designed for pumping highly viscous, sensitive, and abrasive substances while meeting strict hygienic standards.

This pump is ideal for applications such as transferring liquid food products like dairy, meat, fruits, and vegetables. Its design prevents any dead zones or crevices where bacteria can accumulate, making it easy to clean and sanitize. Additionally, the pump’s gentle handling reduces product damage or shear, ensuring high-quality end products.

The NETZSCH NEMO® SH Plus Hygienic Pump has a wide range of flow rates and pressures, making it suitable for various food processing stages, including filling, metering, and dosing. Its robust construction and customizable features make it an ideal choice for food production facilities that require reliable and efficient pumping solutions.

Overall, the NETZSCH NEMO® SH Plus Hygienic Pump offers a hygienic, efficient, and reliable solution for food processing applications, making it an essential tool in the food industry.

Advantages of the NEMO® SH Plus Hygienic Pump

- foodstuff-suitable shaft seals with compression-proof bolted seal casing enable reversal of the direction of rotation and

- thereby also of the direction of conveyance, up to the maximum pump pressure

- streamlined, crevice-free housing model prevents sedimentation of the product

- all product-contacting surfaces are polished to prevent build-up of the medium and facilitate cleaning

- the pump housing and stator can be optionally heated

People Also Ask