Netzsch NM038BY01L06B Netzsch Instruments

NETZSCH NM038BY01L06B

Netzsch NM038BY01L06B by block pump in industrial design can be used in environmental technology, the food and chemical industries, but also in the oil & gas upstream as well as the mid- /downstream sector for a wide variety of pressure-stable conveying or dosing tasks.

From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity.

The Features Of NETZSCH NM038BY01L06B

The NEMO NM038 in industrial design can be used in environmental technology, the food and chemical industries, but also in the oil & gas upstream as well as the mid- /downstream sector for a wide variety of pressure-stable conveying or dosing tasks.Nemo Pumps

The working principle of NETZSCH NM038BY01L06B

- From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO® BY progressive cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity.

- The progressing pump guarantees flow rates proportional to speed with high dosing accuracy over the entire speed range. In block design with flanged drive, this NETZSCH NEMO Pump is especially compact and economical. Moreover, the NEMO® BY is distinguished by its low investment, operating and maintenance costs. Four rotor/stator geometries are available for the various products and applications.

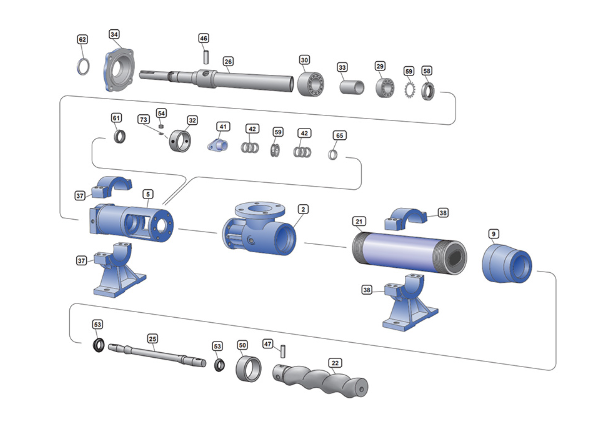

NETZSCH NM038BY01L06B Specification List/NETZSCH NEMO Pump Parts List

| Manufacturer | PMV |

| INLET/OUTLET CONNECTION TYPE | Flange |

| INLET SIZE | 3 in x 2.5 in |

| MOTOR VOLTAGE | 230-460 VAC |

| HORSEPOWER | 3 |

People Also Ask