Sanitary Screw Pump

Efficient and Hygienic Liquid Transfer Made Easy with Sanitary Screw Pumps

Brief description: The sanitary screw pump meets the sanitary standards and is made of polished stainless steel. It can be customized with a cart funnel. It can transport a wide range of liquids with different types and viscosities. It can be customized with stepless speed regulation or electromagnetic speed regulation according to requirements. The flow is uniform and continuous, and the vibration is small. Compared with other rotary pumps, it is less sensitive to incoming gas and impurities.

Features of Sanitary Screw Pum for Liquid Transportation

- Sanitary screw pump standard, stainless steel polished treatment, customizable cart and hopper.

- Wide range of types and viscosity of transported liquids; customizable infinite speed regulation and electromagnetic speed regulation according to demand.

- Uniform and continuous flow, low vibration.

- Compared with other rotary pumps, less sensitive to entering gases and pollutants.

- Solid structure, easy to install and maintain.

The Working Principle Of Sanitary Screw Pump

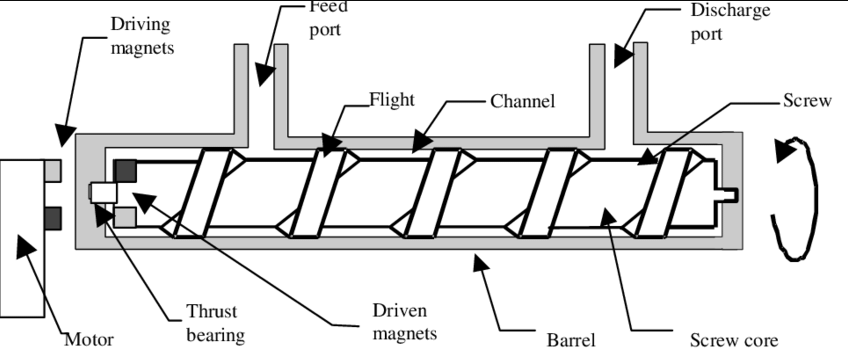

It is a screw pump sanitary that operates on the principle of a helical meshing volumetric pump, with the main working components being the eccentric screw (rotor) and the fixed liner (stator).

Due to the geometric shapes of these two components, they form separate sealed chambers, and the medium flows uniformly in the axial direction. The internal flow velocity is low, and the volume remains constant and the pressure is stable, so it will not generate eddies and agitation. The output pressure of each stage of the pump is 0.6 MPa, the lift is 60m (for clear water), and it is suitable for conveying media with a temperature of below 80°C (and up to 150°C if required).

As the stator is made of various elastic materials, this pump is suitable for conveying high viscosity fluids, as well as media containing hard suspended particles or fibers. Its flow rate is proportional to the speed.

The transmission can be directly driven by a coupling or by a speed-regulating motor, triangle belt, gearbox, and other devices for speed regulation.

This pump has fewer parts and is easy to maintain. The rotor and stator are the vulnerable parts of the pump and are easy to disassemble and install.

It is used in various industries to transport various media, with continuous and constant pressure, no pulsation, and no damage to the conveyed medium. The flow rate can be changed by adjusting the speed to achieve metering purposes. It is suitable for conveying media with the following characteristics: high solids content (with a large particle size of up to 50mm) or media with no solid content, various viscosities (1mPas-3 million mPas), thixotropy and expandability, shear sensitivity, and corrosion resistance (pH=0-14).

Operating Guidelines for Sanitary Screw Pump Efficiency and Longevity

1、It is strictly prohibited to operate the pump without liquid in the pump chamber. Before starting the pump, the liquid must be injected into the pump body from the pump inlet to avoid wearing the stator due to idling.

2、Before starting, the operating direction must be determined and cannot be reversed.

3、For a newly installed or a pump that has been stopped for several days, it should not be started immediately. Instead, a suitable amount of lubricant or conveyed liquid should be injected into the pump body, and the pump should be rotated several times with pliers before starting.

4、After conveying high-viscosity liquid or corrosive medium, the pump chamber should be flushed with water or solvent to prevent blockage and avoid difficulties in the next start-up, which may damage the stator.

5、In winter, if the temperature is too low or the pump is not used, the pump should be drained to prevent the pump body from freezing or the stator from being pulled apart when starting next time.

6、The bearing box should be regularly lubricated during use. If there is leakage at the shaft end, the oil seal should be promptly handled or replaced.

7、If an abnormal situation occurs during operation, the pump should be stopped immediately to investigate the cause and troubleshoot the problem.

People Also Ask