Sludge Screw Pump

What is Sludge Screw Pump?

Sludge screw pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes’ screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw’s spindle.

The specific application of the sludge screw pump, also known as a single screw pump, in sludge and sewage treatment involves using the rotation of the eccentric single helix screw within the double helix liner to move the sludge and sewage along the helical groove from the suction port to the discharge port. This is the working principle of the sludge screw pump.

Advantages of a sludge screw pump

The sludge screw pump, also known as a single screw pump, has common advantages of screw pumps. It is suitable for conveying low-viscosity media such as water, and is especially suitable for conveying suspensions containing solid particles or short fibers, as well as highly viscous media.

1、Wide range of pressure and flow rate. The pressure is about 3.4-340 kgf/cm2, and the flow rate can reach 18600 cm3/min.

2、Wide range of liquid types and viscosity.

3、Due to the low inertia force of the rotating parts inside the sludge screw pump, it can be used at very high speeds.

4、Good suction performance and self-priming ability.

5、Uniform and continuous flow, low vibration, and low noise.

6、Compared with other rotary pumps, it is less sensitive to gas and debris entering.

7、Solid structure and easy installation and maintenance.

Working principle of a sludge screw pump

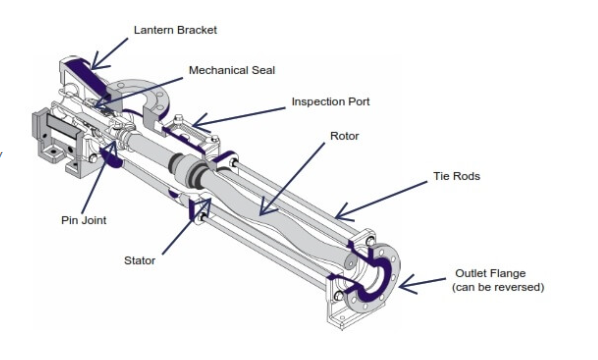

A sludge screw pump is a type of screw pump for sludge, and its main working components are the screw (also known as the rotor) of the eccentric helix and the screw lining (also known as the stator) with a double helix surface on its inner surface. The working principle is that when the electric motor drives the pump shaft to rotate, the screw rotates around its own axis on one hand, and rolls along the inner surface of the lining on the other hand, thus forming the sealed chamber of the pump. When the screw rotates one revolution, the liquid in the sealed chamber advances one pitch forward. With the continuous rotation of the screw, the liquid is pressed from one sealed chamber to another in a helical manner, and finally squeezed out of the pump body. The screw pump is a new type of mechanical equipment for transporting liquid, which has the advantages of simple structure, safe and reliable operation, easy use and maintenance, continuous and uniform liquid discharge, and stable pressure.

The sludge screw pump is a pump that uses the rotation of the screw to suction and discharge liquids. It is most suitable for suction and discharge of viscous liquids.

Application range of sludge screw pumps

The single screw pump belongs to the positive displacement pump. The rotor is made of stainless steel or 40 chromium, and the stator is made of medium-hardness rubber. Therefore, this pump is most suitable for conveying thick and viscous media with solid particles, such as in the sewage treatment industry. For example:

1、Conveying syrup, sugar juice, pulp, and sugar beet residue in sugar mills;

2、Loading and conveying of milk powder, starch, honey, coffee, milk, cream, edible oil, various vitamin solutions, maltose, tomato sauce, jam, mayonnaise, ice cream, etc. in canning and food factories;

3、Feeding and mixing of alcoholic beverages, spices, and fermentation liquids in breweries, as well as the conveying of feed for pressure filters and grain residue;

4、Conveying fish liver oil, fish oil, fish floss, and fish residue in fish processing plants;

5、Conveying sugar juice and fruit juice in fruit processing plants, smashing citrus fruits and other fruits, and feeding materials for filling machines;

6、Loading and conveying of edible oil, rice, corn starch, and other materials in grain and oil processing plants;

7、Conveying animal by-products, fat, and waste liquid in meat processing plants;

8、Feeding and transportation of various vitamin solutions, medicinal liquids, and emulsions in pharmaceutical factories, as well as the conveying of suspensions, saline water, salt sludge, and medicinal residues;

9、Conveying of acid and alkali liquids, various suspensions, fats, glues, chemical dyes, paints, various adhesives, ointments, and pastes in the chemical industry, especially for high-viscosity materials or materials with solid particles that cannot be transported by ordinary centrifugal pumps;

10、Mixing and conveying of ink;

11、Conveying of pulp and ink in paper mills;

12、Conveying of oil products, fats, and waste liquid sludge in petrochemical plants;

13、Conveying of acetylene plant carbide sludge;

14、Conveying of mortar, lime milk, mortar, cement slurry, etc. in the construction industry;

15、Used for the transportation and loading of pumping and feeding in the feed processing process;

16、Widely used in the sewage and sludge treatment industry in industrial and daily life. Sewage usually contains many suspended substances with certain corrosiveness and viscosity, often containing solid particles, and it is appropriate to use thick slurry pumps for transportation;

17、Used for the transportation of contaminated water, contaminated liquids, and other materials in atomic energy launch sites;

18、Discharging wastewater and sludge in mines.

Optimizing Screw Pump Design for Efficient Fluid Transfer

Screw pump design refers to the process of creating a mechanism that utilizes rotating screws to move fluids or substances. It involves the careful arrangement and configuration of the screws, taking into account factors such as pitch, diameter, and thread profile. The design aims to optimize the pump’s efficiency, performance, and durability, ensuring smooth and reliable fluid transfer in various industrial applications.

People Also Ask