Progressive cavity pump spare parts

PMS supplies (both original and generic) replacement progressive cavity pump spare parts such as rotors, stators, coupling rod, driving shaft, seals, and are suitable for many well-known popular brands PC pumps. We have enough stock to ship at any time.

CONTACTAftermarket PCM® Progressive Cavity Pumps and Pump Parts

At our company, we specialize in offering replacement parts and pumps for PCM ® Brand I series, ID series, and H series aftermarket progressive cavity pumps. Our inventory includes stators, rotors, coupling rods, universal joint assemblies, drive shafts, mechanical seals, mechanical seal casings, packing, packing chambers, and pump bodies. We strive to provide our customers with high-quality aftermarket progressive cavity pump solutions that meet their specific needs and requirements.

Ready to Ship Just for You

Complete models and large stock of progressive cavity pump parts!

The Stator of a Progressive Cavity Pump

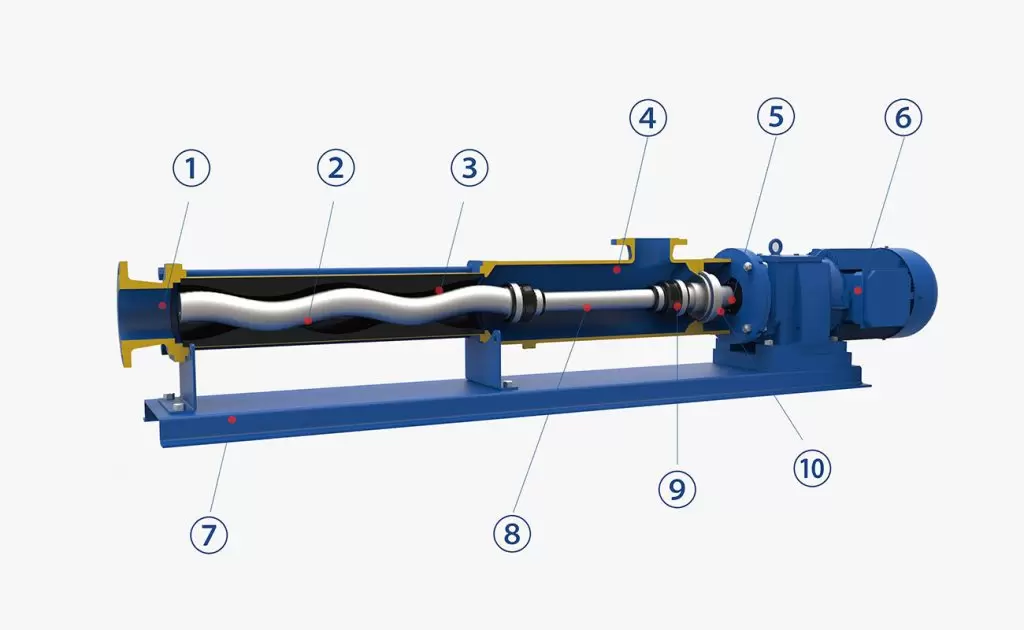

The stator is mostly made of rubber. Because it needs to form a closed meshing cavity with the rubber stator, it is an interference fit with the rotor. When the rotor (main shaft) rotates and causes continuous friction, it will wear naturally.

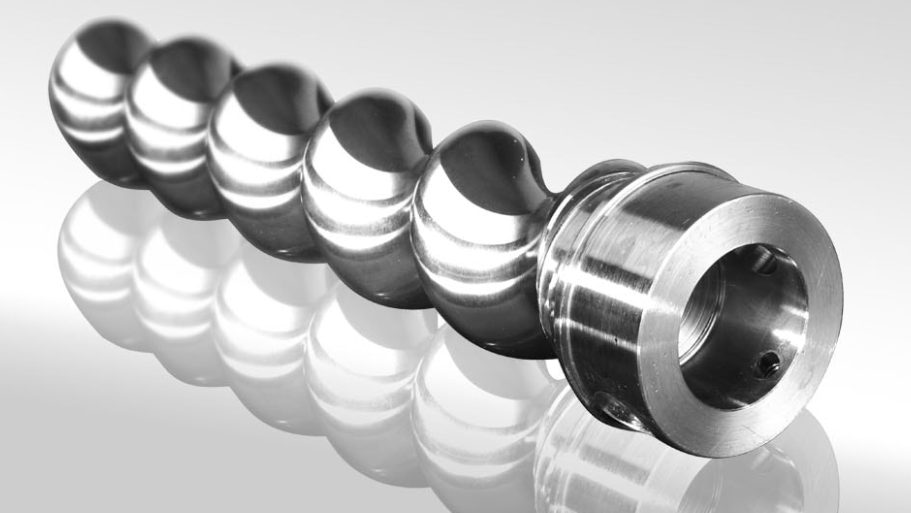

The Rotor of a Progressive Cavity Pump

The Progressive cavity pump rotor (also known as the main shaft) is mostly made of stainless steel, and can be selectively plated with chrome;

Due to its meshing relationship with the characteristic geometry of the stator, in addition to natural wear, it is also whether the conveyed medium contains solid particles and corrosive.

The Coupling Rod of a Progressive Cavity Pump

The coupling rod connects the rotor and the drive shaft. When the motor is running, the drive shaft drives the coupling rod, and the coupling rod then drives the rotor to play a transmission role. Except for the drive shaft, these mechanical components are located in the suction chamber of the pump.

The Drive Shaft of a Progressive Cavity Pump

The drive shaft is generally connected to the drive end (reducer or various drive motors), and its wear is mostly caused by natural wear or changes in media working conditions.

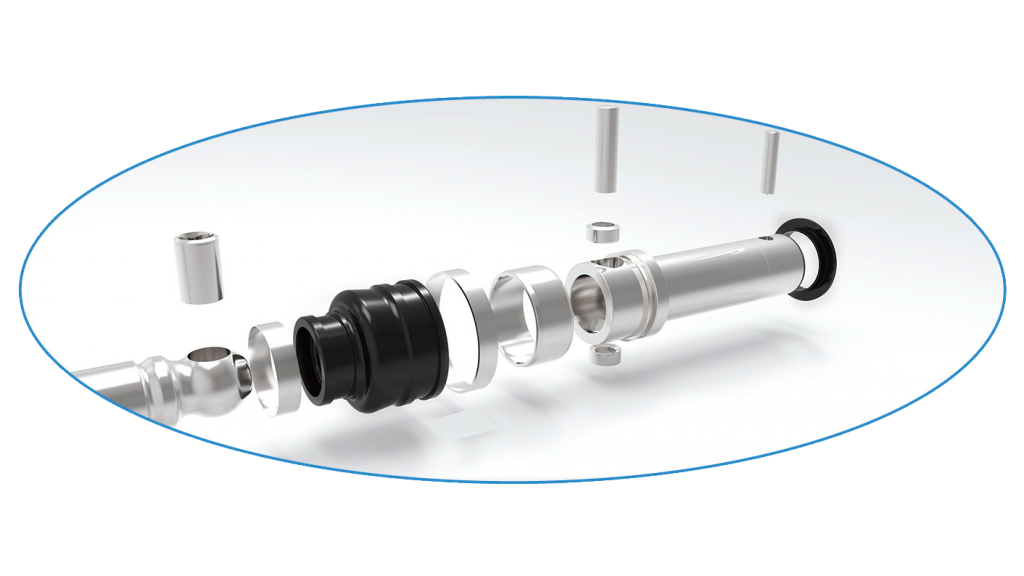

The Universal Joint Assembly a Progressive Cavity Pump

The universal joint assembly is located at both ends of the coupling rod. It successfully connects the rotor and the drive shaft to the coupling rod more stably and firmly; Since the universal joint assembly consists of a variety of small spare parts, we need to check its seal regularly And lubrication.

Mechanical Seal

Mechanical seals are generally used to transport media with corrosion resistance, high moisture content or no particles or even a small amount of particles.

Advantages: Long life, no leakage, good vibration resistance, and a wide range of applications;

Disadvantages: Complex structure, high processing requirements, troublesome installation and replacement.

Packing Seal

The packing seal is mostly polytetrafluoroethylene packing, which is generally used for conveyor belt particles or media with low moisture content;

Advantages: The packing seal is wear-resistant, low cost, easy to install and replace;

Disadvantages: The medium will leak out of the stuffing box as drops and needs to be cleaned regularly.

Progressive cavity pump parts material list

| No. | Name | Matiral |

|---|---|---|

| 1 | Material-out chamber | HT200, 1Cr18Ni9Ti, 304, 316L, 2205, Ti |

| 2 | Rotor | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 3 | Stator | NR, NBR, Q, EPM, FKM |

| 4 | Suction chamber | HT200, 304, 316L, 2205, Ti |

| 5 | Driving shaft | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 6 | Gear motor | / |

| 7 | Base plate | 45#, 2Cr13, 304, 316L, 2205, Ti |

| 8 | Coupling rod | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 9 | Universal joint assembly | NBR + 45#, 2Cr13, 304, 316L |

| 10 | Shaft sealing | Customized according to media |

Aftermarket Netzsch® Progressive Cavity Pumps and Netzsch Pumps Parts

PMS Pump stocks Netzsch® Brand NE series and NM series replacement aftermarket Netzsch pump parts and progressive cavity pump parts. Including stator, rotor, coupling rod, universal joint assembly, drive shaft, mechanical seal, mechanical seal casing, packing, packing chamber and pump body, almost all can be provided, except for special pump types.

Netzsch® NM series progressive pump parts list

Pump identification no. N010844-NM031BY01P05B (For reference only)

| Part no. | Description | Quantity | Identification no. |

|---|---|---|---|

| pin | 2 | NLP8000068 | |

| hexagon. Nut | 2 | NLP6007847 | |

| 0085 | drive stool | 1 | 5066509 |

| 0365 | elbow | 1 | 520096 |

| 1020 | name plate | 1 | NLP8000314 |

| 1020 | number plate | 1 | 892897 |

| 1030 | pin | 1 | 5067630 |

| 1035 | thrower | 1 | NMP5066416 |

| 1050 | connecting shaft | 1 | NLP6002301 |

| 1998 | coupling rod | 1 | NLP6000534 |

| 1999 | rotor | 1 | 5060244 |

| 2005 | end socket | 1 | 955217 |

| 2010 | pump housing | 1 | NLP6011279 |

| 2015 | drain plug | 3 | NLP8000290 |

| 2016 | drain plug | 1 | NLP8000269 |

| 2020 | bolt | 4 | 687463 |

| 2035 | support | 1 | 955466 |

| 3005 | stator | 1 | 5072602 |

| 3010 | thru bolt | 4 | 955464 |

| 3015 | spring washer | 8 | 502014 |

| 3070 | washer | 4 | 502002 |

| 5065 | circlip | 2 | 512277 |

| 5115 | sleeve | 2 | 861394 |

| 5425 | clamp ring | 2 | NLP8000448 |

| 7015 | stuffing box housing | 1 | NLP6001432 |

| 7030 | bolt | 2 | NLP8000387 |

| 7040 | packing | 6 | 691464 |

| 8010 | gasket | 3 | 422526 |

| 8012 | gasket | 1 | 422527 |

| 8015 | O-ring | 1 | 516326 |

| 8060 | O-ring | 4 | 516955 |

| 8235 | SM-pin joint seal | 2 | 878237 |

| 9510 | helical geared motors | 1 | RC06900 |

Netzsch pump parts list

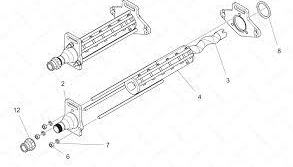

Aftermarket Seepex® Parts and Progressive Cavity Pumps and Pump Parts

We specialize in providing replacement aftermarket progressing cavity pumps parts and pumps for Seepex BN series and Seepex MD series, which includes stator, rotor, coupling rod, universal joint assembly, drive shaft, mechanical seal, mechanical seal casing, packing, packing chamber, and pump body. We can provide almost all Sepeex pump parts, except for special pump types and we can also offer seepex aftermarket.Seepex bn 1-6l manual

The impressive features of SEEPEX original parts are:

- Superior performance due to precise engineering

- Proven reliability

- High part durability

- Short delivery times due to warehouses worldwide

- Low abrasion

Index of Seepex BN series spare parts and recommended spare/reserve parts

05-24, 1-6, 1-12, 2-6L…202-6L

| Part No. | Description | Quantity |

|---|---|---|

| 200 | lantern | 1 |

| 202 | round head grooved pins | 2 |

| 203 | type plate | 1 |

| 210 | hexagon bolt | 4 |

| 211 | hexagon bolt | |

| 212 | spring washer | 4 |

| 213 | hexagon nut | 4 |

| 307 | plug-in shaft | 1 |

| 309 | plug-in shaft pin | 1 |

| 310 | splash ring | 1 |

| 400 | coupling rod | 1 |

| 401 | retaining sleeve | 2 |

| 402 | coupling rod pin | 2 |

| 403 | guide bushing | 4 |

| 404 | coupling rod bushing | 2 |

| 405 | universal joint sleeve | 2 |

| 406 | holding band | 2 |

| 407 | holding band | 2 |

| 500 | suction casing | 1 |

| 501 | casing gasket | 1 |

| 502 | screwed plug | 3 |

| 503 | sealing ring | 3 |

| 506 | hexagon bolt | 4 |

| 507 | fan type lock washer | 4 |

| 509 | hexagon nut | 4 |

| °) 510 | cleanout | 2 |

| °) 511 | gasket | 2 |

| °) 512 | hexagon bolt | 8 |

| °) 516 | screwed plug | 2 |

| °) 517 | sealing ring | 2 |

| 600 | rotor | 1 |

| 601 | stator | 1 |

| 602 | tie bolt | 2 |

| 603 | tie bolt | 2 |

| 604 | hexagon nut | 8 |

| 606 | washer | 8 |

| 607 | trestle | 1 |

| 700 | pressure branch | 1 |

| 705 | screwed plug | 1 |

| 706 | sealing ring | 1 |

| 098 | seepex joint grease |

Table of seepex bn pump manual series spare parts and recommended spare/reserve parts/spare parts for seepex pumps/seepex md/seepex bn 5-6l manual

Aftermarket Mono® Progressive Cavity Pumps and Pump Parts

stator mono pump/pump stator

We provide you pumps and pump part,replacement parts or after market for the following Mono® Pump Models.

- Mono® D Series Pumps*

- Mono® H Series Pumps*

- Mono® Merlin Pumps*

- Mono® E series Pumps*

- Mono® C Series Pumps*

- Mono® L Series Pumps*

- Mono Merlin Pump*

Drawing Reference Numbers

C1XK AND ABOVE EXCLUDING 4 – STAGE MODELS

| DRG. REF | DESCRIPTION | DRG. REF | DESCRIPTION |

|---|---|---|---|

| 01A | BODY-STD C.I. | P201 | TAPER PLUG |

| 10A | MECHANICAL SEAL | P202 | TAPER PLUG |

| 15A | THROWER GUARD | P203 | HEX. SOC. SETSCREW |

| 20B | GASKET-GLAND | ||

| 22A | STATOR-MTM NITRILE RUBBER | P401 | TORL SEAL RING |

| 23A | SUCTION CHAMBER | P402 | TORL SEAL RING |

| 23B | SUCT CHAMB EXTENSION | P403 | SPIRAL RET.RING |

| 24A | END COVER | P404 | SPIRAL RET.RING |

| 25A | ROTOR | P405 | TIE-SEALING COVER |

| 26A | COUPLING ROD | P406 | TIE SEALING COVER |

| 28A | SEALING COVER | ||

| 28B | SEALING COVER | P501 | TAPER PLUG |

| 29A | COUPLING ROD PIN | P502 | TAPER PLUG |

| 29B | COUPLING ROD PIN | P503 | HEX. NUT |

| 29C | SHAFT PIN | P504 | WASHER |

| 32A | DRIVE SHAFT | P505 | SNGL. COIL SPR. WASHER |

| 42A | THROWER | P506 | HEX. NUT |

| 62A | SUPPORT FOOT | P507 | WASHER |

| 65A | MECH SEAL CARRIER | P508 | SNGL. COIL SPR. WASHER |

| 66A | ABUTMENT RING | P509 | TORL SEAL RING |

| 74A | SLEEVE (ROTOR-SHAFT) | P510 | TORL SEAL RING |

| 74B | SLEEVE (ROTOR-SHAFT) | P519 | TAPER PLUG |

| 95A | TIE ROD | P520 | HEX. HD. BOLT |

| P521 | HEX. NUT | ||

| P104 | HEX. HD. BOLT | P522 | WASHER |

| P105 | HEX. NUT | P523 | SNGL. COIL SPR. WASHER |

| P106 | WASHER | ||

| P107 | SNGL. COIL SPR. WASHER | P601 | HEX HD BOLT |

| P109 | HEX NUT | P602 | SNGL. COIL SPR. WASHER |

| P603 | WASHER | ||

| P604 | HEX. NUT |

Drawing Reference Numbers List(Mono Pump Parts List) mono pump rotor

Aftermarket Moyno® Progressive Cavity Pumps and Replacement Moyno Parts

We provide you with aftermarket pumps and moyno pump parts for the following Moyno® Pump Models.

- Moyno® 500 Series Pumps*

- Moyno® 1000 Series Pumps*

- Moyno® 2000 Series Pumps*

- Moyno® J-Series Pumps*

- Moyno® L-Frame Pumps – Our Most Popular!*

- Moyno® FF / FG / FFC / FGC & FFJ Sanitary Pumps*

Index of spare replacement moyno parts and recommended spare/reserve parts

| REF. DESCRIPTION | TYPE | A2A PART NO. | A1B PART NO. | A2B PART NO. | A1C PART NO. | A2C PART NO. |

|---|---|---|---|---|---|---|

| 0100 BEARING HOUSING | CD/SS | CC A2A0110 | CC A2A0110 | CC A2A0110 | CC A2A0110 | CC A2A0110 |

| 0900 PACKING GLAND | CD/SS | SC A2A0910 | SC A2A0910 | SC A2A0910 | SC A2A0910 | SC A2A0910 |

| 1000 STUFFING BOX | CD SS | CC A2A1010 SC A2A1010 | CC A2A1010 SC A2A1010 | CC A2A1010 SC A2A1010 | CC A2A1010 SC A2A1010 | CC A2A1010 SC A2A1010 |

| 1000 SEAL * HOUSING ** | CD/SS CD/SS | SC A2A1011 4240833007 | SC A2A1011 4240833007 | SC A2A1011 4240833007 | SC A2A1011 4240833007 | SC A2A1011 4240833007 |

| 1100 SUCTION CHAMBER | CD SS | CC A2A1110 SC A2A1110 | CC A1B1110 SC A1B1110 | CC A1B1110 SC A1B1110 | CC A1C1110 SC A1C1110 | CC A1C1110 SC A1C1110 |

| 1200 STATOR GASKET | Q/R F B | GG A2A1200 GF A2A1200 GB A2A1200 | GG A1B1200 GF A1B1200 GB A1B1200 | GG A1B1200 GF A1B1200 GB A1B1200 | GG A1C1200 GF A1C1200 GB A1C1200 | GG A1C1200 GF A1C1200 GB A1C1200 |

| 1220 SUCTION CHAM. GASKET | Q/R F B | GG A2A1220 GF A2A1220 GB A2A1220 | GG A2A1220 GF A2A1220 GB A2A1220 | GG A2A1220 GF A2A1220 GB A2A1220 | GG A2A1220 GF A2A1220 GB A2A1220 | GG A2A1220 GF A2A1220 GB A2A1220 |

| 1400 DISCHARGE FLANGE | CD SS | MS A2A1410 SS A2A1410 | MS A1B1410 SS A1B1410 | MS A1B1410 SS A1B1410 | MS A1C1410 SS A1C1410 | MS A1C1410 SS A1C1410 |

| 1700 STATOR SUPPORT | CD/SS | MS A2A1710 | MS A2A1710 | MS A2A1710 | MS A1C1710 | MS A1C1710 |

| 1800 CLAMP RING | CD/SS | MS A2A1810 | MS A1B1810 | MS A1B1810 | MS A1C1810 | MS A1C1810 |

| 2000 SHAFT PIN | CD/SS | 4220487017 | 4220487017 | 4220487017 | 4220487017 | 4220487017 |

| 2100 INTERMEDIATE SHAFT | CD SS | 4250392001 4250392017 | 4250392001 4250392017 | 4250392001 4250392017 | 4250393001 4250393017 | 4250393001 4250393017 |

| 2200 SEAL RING | Q/R F B | 3207902206 3207905206 3207904206 | 3207902206 3207905206 3207904206 | 3207902206 3207905206 3207904206 | 3207902206 3207905206 3207904206 | 3207902206 3207905206 3207904206 |

| 5000 ROTOR | CD SS | TS A2A5000 SS A2A5000 | TS A1B5000 SS A1B5000 | TS A2B5000 SS A2B5000 | TS A1C5000 SS A1C5000 | TS A2C5000 SS A2C5000 |

| 6000 DRIVE SHAFT | CD SS | AS A2A6000 SS A2A6000 | AS A2A6000 SS A2A6000 | AS A2A6000 SS A2A6000 | AS A1C6000 SS A1C6000 | AS A1C6000 SS A1C6000 |

| 6000 DRIVE SHAFT (2-PIECE OPTION) | CD SS | 4250378001 4250378017 | 4250378001 4250378017 | 4250378001 4250378017 | 4250378001 4250378015 | 4250378001 4250378015 |

| 6100 RETAINING RING | CD/SS | ST A2A6100 | ST A2A6100 | ST A2A6100 | ST A1C6100 | ST A1C6100 |

| 6200 CONNECTING ROD | CD/SS | AS A2A6200 | AS A2A6200 | AS A2A6200 | AS A1C6200 | AS A1C6200 |

| 6300 DRIVE PIN | CD/SS | TR A2A6300 | TR A2A6300 | TR A2A6300 | TR A1C6300 | TR A1C6300 |

| 6400 JOINT SEAL | Q/R F/B | RD A2A6400 RF A2A6400 | RD A2A6400 RF A2A6400 | RD A2A6400 RF A2A6400 | RD A1C6400 RF A1C6400 | RD A1C6400 RF A1C6400 |

| 6500 STATOR | Q R F B | RQ A2A6510 RR A2A6510 RF A2A6510 RB A2A6510 | RQ A1B6510 RR A1B6510 RF A1B6510 RB A1B6510 | RQ A2B6510 RR A2B6510 RF A2B6510 RB A2B6510 | RQ A1C6510 RR A1C6510 RF A1C6510 RB A1C6510 | RQ A2C6510 RR A2C6510 RF A2C6510 RB A2C6510 |

| 6800 SLINGER RING | CD/SS | RZ A2A6800 | RZ A2A6800 | RZ A2A6800 | RZ A2A6800 | RZ A2A6800 |

| 6800 SLINGER/PIN RETNR (2-PIECE OPTION) | CD/SS | 423052800 | 423052800 | 423052800 | 423052800 | 423052800 |

| 6850 LANTERN RING | CD/SS | GR A2A6850 | GR A2A6850 | GR A2A6850 | GR A2A6850 | GR A2A6850 |

| 6900 PACKING | STD. PTFE | PC A2A6901 3403655001 | PC A2A6901 3403655001 | PC A2A6901 3403655001 | PC A2A6901 3403655001 | PC A2A6901 3403655001 |

| 7000 NAME PLATE | CD/SS | GA A2A7000 | GA A2A7000 | GA A2A7000 | GA A2A7000 | GA A2A7000 |

| K O-RING | Q/R F/B | CA137 CF137 | CA137 CF137 | CA137 CF137 | CA141 CF141 | CA141 CF141 |

| J SNAP RING | CD SS | EB007 EB507 | EB007 EB507 | EB007 EB507 | EB015 EB015 | EB015 EB015 |

| R STATOR RING | CD/SS | EC022 | EC028 | EC028 | EC034 | EC034 |

moyno pump replacement/aftermarket moyno pump parts

*FRICTION DRIVEN SEAL, TYPE 43 OR EQUAL

**POSITIVE DRIVE SEAL, TYPE 680 OR EQUAL

NOTE: CONTACT FACTORY FOR REPLACEMENT MECHANICAL SEAL PART NUMBERS

Aftermarket Allweiler® Progressive Cavity Pumps and Pump Parts

Although Allweiler pump has a tailored code, we can provide most allweiler pump parts.

- Allweiler® SEP Series Pumps*

- Allweiler® SNP Series Pumps*

- Allweiler® AE Series Pumps*

- Allweiler® TecFlow Series Pumps*

Index of spare parts and recommended spare/reserve parts

Series AEB.E, AEB.N, AEB.H, AEB.L, AEDB.E, AEDB.N Design IE

| Part no. | Description | Recommended allweiler spare parts: | Quantity | Mark |

|---|---|---|---|---|

| 122 | Motor bracket | 1 | ||

| 123 | Clamp set | 1 | ||

| 125 | Hollow shaft | R | 1 | |

| 201 | T-head bolt | 2 | ||

| 202 | Self locking nut | 2 | ||

| 203 | Gland | 1 | ||

| 204 | Gland housing | 1 | ||

| 207 | Gland packing | R, r | ① | |

| 208 | Flushing ring | 1 | ||

| 209 | Lantern ring | 1 | ||

| 212 | Screw plug | 1 | ||

| 213 | Sealing tape | 1 | ||

| 214 | Mechanical seal housing | 1 | ||

| 215 | Mechanical seal cover | 1 | ||

| 218 | O-ring | R | 1 | |

| 219 | Mechanical seal | R | 1 | |

| 220 | Retaining pin | 1 | ||

| 232 | Shaft seal ring | R | 1 | |

| 234 | Throttle ring | R | 1 | |

| 235 | O-ring | R | 1 | |

| 236 | Retaining pin | R | 2 | |

| 245 | Hexagon head bolt | 3 | ||

| 251 | Sealing agent | 1 | ||

| 301 | Coupling rod pin | R, r | 2 | |

| 302 | Coupling rod bush | R, r | 2 | ⑤ |

| 303 | Guide bush | R, r | 4 | |

| 304 | Retaining sleeve | R, r | 2 | |

| 305 | Joint oil | R, r | ① | |

| 306 | Clamping band | R, r | 4 | |

| 307 | Coupling rod | R, r | 1 | |

| 308 | Cover sleeve | R, r | 2 | |

| 401 | Rotor | R, r | 1 | |

| 402 | Stator | R, r | 1 | |

| 403 | Stator gasket, discharge side | R, r | 1 | |

| 404 | Stator gasket, suction side | R, r | 1 | |

| 501 | Suction casing gasket | R, r | 1 | |

| 502 | Screw plug | 1 | ||

| 503 | Seal ring | R | 1 | ③ |

| 504 | Discharge casing | 1 | ③ | |

| 505 | Suction casing | 1 | ||

| 506 | Suction casing cover | 2 | ||

| 507 | Gasket | R | 2 | |

| 508 | Stud | 8 | ||

| 509 | Nut | 8 | ||

| 512 | Reducing flange | 1 | ||

| 513 | O-ring | R | 1 | |

| 525 | Washer | 8 | ||

| 601 | Name plate | 1 | ||

| 602 | Dome headed groove pin | 4 | ||

| 603 | Commissioning label | 1 | ||

| 604 | Suction label | 1 | ||

| 605 | Discharge label | 1 | ||

| 606 | Hexagon head bolt | 4 | ||

| 607 | Hexagon nut | 4 | ||

| 608 | Serrated lock washer | 4 | ||

| 609 | Hexagon nut | 4 | ||

| 610 | Washer | 4 | ||

| 611 | Connecting bolt | 4 | ||

| 612 | Stay | 1 | ② | |

| 613 | Hexagon nut | 2 | ④ |

Table of screw pump spare parts list and recommended spare allweiler pumps spare parts allweiler pump spares/progressive cavity pump latex

allweiler progressive cavity pump

Recommended spare parts:

R = large repair kit

r = small repair kit

- ① See Section 7.1.2.4

- ② 2 pieces for AEB4H 100-IE, AEB4H 200-IE

- ③ 2 pieces for connection piece positions 2 and 4

- ④ 4 pieces for AEB4H 100-IE, AEB4H 200-IE

- ⑤ not required for AEB1E 50 / AEB2E 50 / AEB1N 25 / AEB2N 25 / AEDB1E 75 / AEDB2N 38 / AEB1L 99 / AEB4H 12)

Aftermarket PCM® Progressive Cavity Pumps and Pump Parts

We offer PCM ® Brand I series, ID series and H series replacement aftermarket progressing cavity pumps parts and pumps. Including stator, rotor, coupling rod, universal joint assembly, drive shaft, mechanical seal, mechanical seal casing, packing, packing chamber and pump body, almost all can be provided, except for special pump types.

Parts of lists

011M6F, 075M6F, 1M6F, 2M6F, 3M6F

| Part no. | Description | Quantity |

|---|---|---|

| 1 | STATOR | 1 |

| 11 | PIN | 1 |

| 13 | SEAL | 1 |

| 16/17 | GASKET | 1 |

| 20 | ROTOR | 1 |

| 34 | SHAFT RING | 1 |

| 36 | CTRL SHAFT | 1 |

| 50 | BODY | 1 |

| 54 | PORT | 1 |

| 57 | MS SUPPORT | 1 |

| 88 | SPACER | 1 |

| 90 | SEAL | 2 |

| 102 | WASHER | 4 |

| 102A | WASHER | 4 |

| 104 | SCREW | 4 |

| 104A | SCREW | 4 |

| 107 | NUT | 8 |

| 110 | PLUG | 1 |

| 110A | PLUG | 1 |

| 111 | PLUG SEAL | 1 |

| 227 | WASHER | 4 |

| 242 | WASHER | 2 |

| 250 | SCREW | 4 |

List of PCM spare parts

Aftermarket Tarby® Pumps and Tarby Pump Parts

Tarby Progressive Cavity Pumps and Tarby Pump Manual

| Liberty Part Description | Liberty p/n | Tarby® p/n |

| Stator 1LL3 CDB EPDM/steel | 1LL3-21BC | 400-30BMAA |

| Stator 1LL3 CDF Viton/steel | 1LL3-21FC | 400-30BFAA |

| Stator 1LL3 CDQ Buna/steel | 1L3-21QC | 400-30BDAA |

| Stator 1LL3 CDR Nat.rubber/steel | 1LL3-21RC | 400-30BKAA |

| Stator 2LL3 CDB EPDM/steel | 2LL3-21BC | 400-30BMBA |

| Stator 2LL3 CDF Viton/steel | 2LL3-21FC | 400-30BFBA |

| Stator 2LL3 CDQ Buna/steel | 2LL3-21QC | 400-30BDBA |

| Stator 2LL3 CDR Nat.rubber/steel | 2LL3-21RC | 400-30BKBA |

| Stator 3LL3 CDB EPDM/steel | 3LL3-21BC | 400-30BMCA |

| Stator 3LL3 CDF Viton/steel | 3LL3-21FC | 400-30BFCA |

| Stator 3LL3 CDQ Buna/steel | 3LL3-21QC | 400-30BDCA |

| Stator 3LL3 CDR Nat.rubber/steel | 3LL3-21RC | 400-30BKCA |

| Stator 6ML2 CDB EPDM/steel | 6ML2-21BC | N/A |

| Stator 6ML2 CDF Viton/steel | 6ML2-21FC | N/A |

| Stator 6ML2 CDQ Buna/steel | 6ML2-21QC | N/A |

| Stator 6ML2 CDR Nat.rubber/steel | 6ML2-21RC | N/A |

| Stator 1LL3 SSB EPDM/SS | 1LL3-21BS | 400-30BRAA |

| Stator 1LL3 SSF Viton/SS | 1LL3-21FS | 400-30BZAA |

| Stator 1LL3 SSQ Buna/SS | 1LL3-21QS | 400-30ABAA |

| Stator 1LL3 SSR Nat.rubber/SS | 1LL3-21RS | 400-30BVAA |

| Stator 2LL3 SSB EPDM/SS | 2LL3-21BS | 400-30BRBA |

| Stator 2LL3 SSF Viton/SS | 2LL3-21FS | 400-30BZBA |

| Stator 2LL3 SSQ Buna/SS | 2LL3-21QS | 400-30ABBA |

| Stator 2LL3 SSR Nat.rubber/SS | 2LL3-21RS | 400-30BVBA |

| Stator 3LL3 SSB EPDM/SS | 3LL3-21BS | 400-30BRCA |

| Stator 3LL3 SSF Viton/SS | 3LL3-21FS | 400-30BZCA |

| Stator 3LL3 SSQ Buna/SS | 3LL3-21QS | 400-30ABCA |

| Stator 3LL3 SSR Nat.rubber/ | 3LL3-21RS | 400-30BVCA |

| Stator 6ML2 SSB EPDM/SS | 6ML2-21BS | N/A |

| Stator 6ML2 SSF Viton/SS | 6ML2-21FS | N/A |

| Stator 6ML2 SSQ Buna/SS | 6ML2-21QS | N/A |

| Stator 6ML2 SSR Nat.rubber/SS | 6ML2-21RS | N/A |

Liberty specializes in Progressive Cavity Pumps for industry. The liberty progressive cavity pumps are positive displacement system that is extremely flexible in its usability in a variety of specialized fields with difficult pumping applications such as viscous and highly-abrasive media. The design offers a pulsation-free, self priming operation that allows solids contents up to 50% to be moved without shearing.

When it comes to moving fluids with suspended solids content such as sludge’s or biosolids or thickened abrasives such as grouts or slurries, the PC Pump is the best choice for your application. Liberty can supply both the multiphase progressive cavity pumps and replacement parts to keep your PC Pump operating optimally for a lower price than other suppliers and OEM’s and can even offer you full pump packages with motors and baseplates if your job requires it.

Liberty Progressive Cavity Pumps are highly efficient and reliable pumping solutions. They are designed to handle a wide range of fluids with precision and consistency. With their advanced technology and durable construction, these pumps ensure optimal performance and longevity in various industries. Whether it’s for industrial processes, wastewater treatment, or oil and gas applications, Liberty Progressive Cavity Pumps deliver exceptional results.progressive cavity biosolids pump liberty pc pumps liberty progressive cavity pump

Progressive Cavity Oem Spare Parts

Advanced Equipment Mature Technology

Machined Rotor

Injection Stator

Machined Drive Shaft

FAQ – Frequently Asked Questions