Single Screw pump

What is single screw pump?

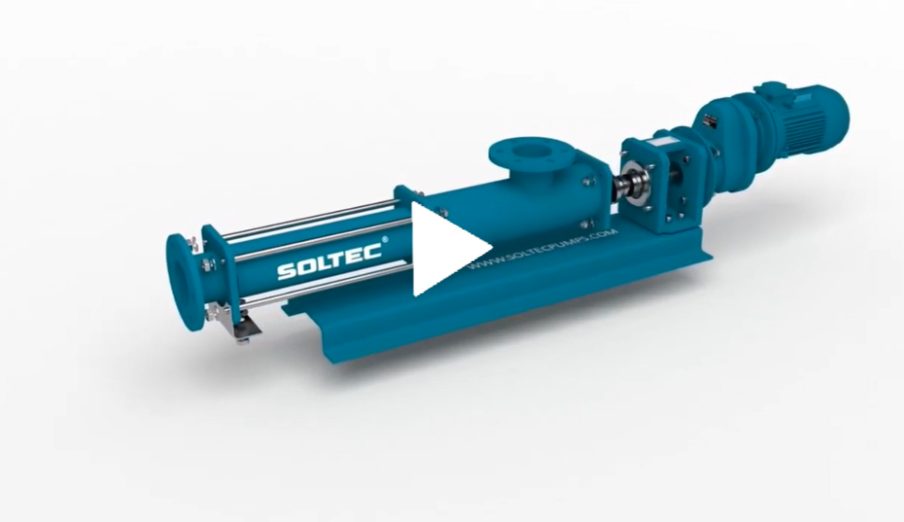

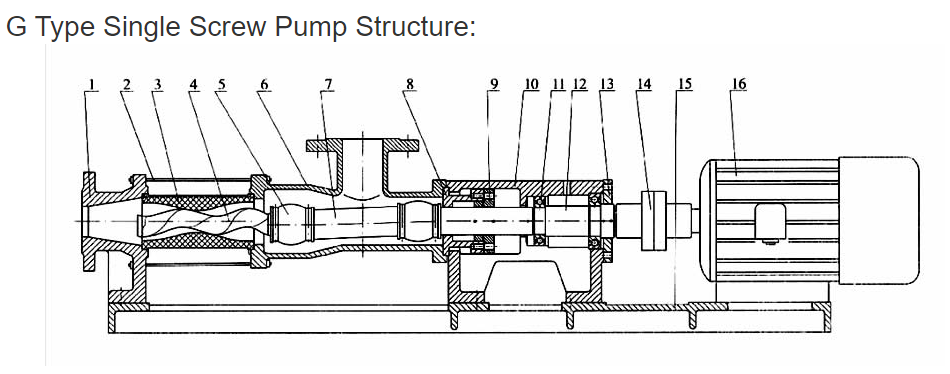

Single screw pump is a type of rotary positive displacement pump that operate according to the positive displacement principle. Single screw pump working principle is based on the interaction between a single-helix metal rotor and a double-helix elastic stator, which creates sealed cavities that move fluid from the suction side to the discharge side.

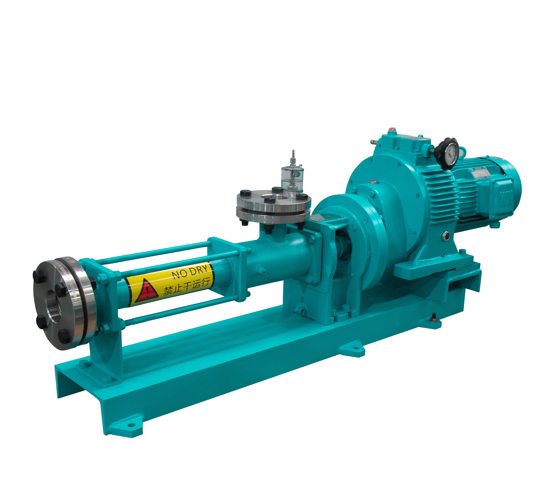

PMV Single Screw Pump Description

Single Screw Pump is a type of positive displacement pump that operates based on the principle of positive displacement. It is characterized by a single-helix metal rotor and a double-helix elastic stator which create sealed cavities. These sealed cavities move the liquid from the suction to the discharge side of the pump. Single screw pumps have a compact structure, small volume, and are easy to maintain. They are widely used in various industries such as food, beverage, chemical, petrochemical, and environmental engineering.

The features of single screw pump

According to API676 standard API 676 Standard

Faultless multi-phase delivery of liquid, gas and solid;

Self suction: Suction is up to 8 meters;

Volume of moving fluid is constant, no torrent, stir and pulse;

High wear resistance when deliver the high solid content through the elastic stator chamber.

It can deliver the fluid with high viscosity and high solid content: the max viscosity is up to 100000CP, the solid content is up to 60%;

The flow is directly proportional to the speed of rotation, the flow can be automatically adjusted by speed regulator;

Constant pressure control and dry running protection.

Valveless system – pump has non-return valve function;

Reversible;

Versatile use in all industries

Single Screw Pump Applications in Various Industries

Single rotary screw pumps are widely apply to the following fields: foodstuff, beverage, wine-making, paper and pulp, power plants, chemical, petrochemical industries, mining, building industries and environmental engineering. In petrochemical industries, they are usually applied to deliver crude oil, thick oil, all kinds of catalyst, polymer (polymer injection in oilfield), oil sludge, oily sewage water and public works.

People Also Ask

Request Quote :