Vertical Screw Pump

Vertical screw pump for creams gels and other dense liquids is used for chemicals, cosmetics, pharmaceuticals and food industries. It can be used for pumping of dense and thin fluids of various viscosities, both neutral and aggressive, such as: creams, gels, paints etc.

CONTACT

What is single vertical screw pump?

Vertical screw pump for creams gels and other dense liquids is used for chemicals, cosmetics, pharmaceuticals and food industries. It can be used for pumping of dense and thin fluids of various viscosities, both neutral and aggressive, such as: creams, gels, paints etc.

| Device mode | SV01-SV12 |

| SV01-SV12 | 0-80℃ |

| Medium viscosity | 0-8000000cps |

| Medium flow | 0-200m3/h |

| Output pressure | 0-4.8mp |

| Rotor material | SUS304; SUS316L; 904L |

| Stator material | Nitrile rubber; EPDM; Viton; Neoprene; Hydrogenated nitrile rubber; Silicone |

| Installation method | vertical |

The Features of Vertical screw pump

Can transport the media containing sand and gravel

| Low pulsation conveying |

| High inhalation capacity |

| Accurate measurement accuracy |

| Low life cycle cost |

| High pressure stability |

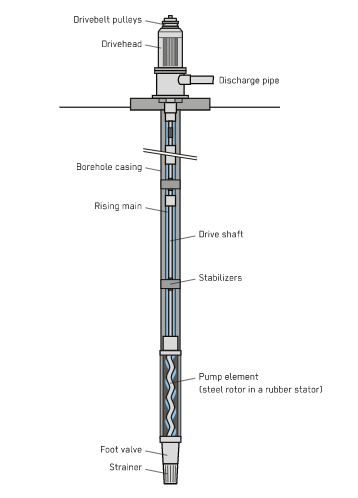

The PMV® SE SeriesImmersible Pump is available in

| Carbon steel |

| 304 |

| 316L |

| Special Materials |

Can be transported:

| Flow 0-120 m³/h |

| Standard pressure up to 24 bar |

And provide a variety of seals, for example

| Packing Seal |

| Shaft SEAL RING |

| mechanical seals with or without cooling with single end face and reversible direction rotation |

| double-end mechanical seals (in-line and back-to-back) |

Wide Spectrum of Applications

The PMV® SE SeriesImmersible Pump is used primarily for substances with the followingproperties…

| Low to high viscosity (1 mPas to 100,000 mPas) | hixotropic and dilatant |

| Shear-sensitive | Abrasive |

| Lubricity or non lubricating | Erosive (PH 0~ 14) |

| Adhesive | Toxic |

| rude oil | Mixed with water and gravel oil |

| Oil/water emulsions | Water in oil deposits |

| Sludge |

PMV Features of the PMV® SE Series Immersible Pump

| The additional suction tube can be attached to the lengthened immersed tube |

| Cavitation allowance (NPSH) can reach the lowest point |

| Can be run forward and backward |

| Low noise, small vibration |

| Temperature range from -40°c to 160°c |

The Advantage of Vertical screw pump

- Can even run in the case of high water content

- Reliable operation in high viscous oil environment

- Suitable for medium with high solids content

Benefits of using a vertical screw pump

The vertical screw pump mixture of surface water and crude oil is accumulated in the well without overflow and reliable conveying oil field. These wells must be emptied. The water and oil mixture will change greatly with the change of temperature and composition ratio. The dive pump can be safely and reliably transported to an oil processing plant from a mixture of up to 15 meters deep.

People Also Ask