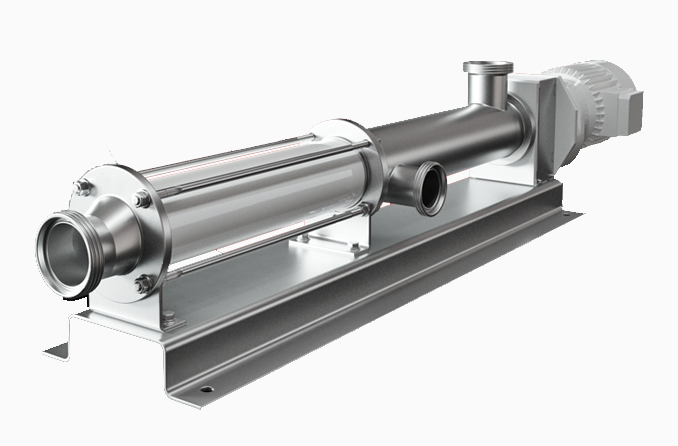

SEEPEX BCF – FLEXROD DESIGN

The BCF food pump and hygienic pump from SEEPEX, with its joint-free, flexible titanium shaft (Flexrod) is certified under 3-A Sanitary Standards. Tangentially positioned flush connections allow residue-free cleaning in CIP and SIP processes. Optimal cleaning and sterilization can also be achieved when disassembled (COP). Thanks to minimal pulsation and shear characteristics, it is particularly suitable for conveying of sensitive food.

Efficient and Reliable: The SEEPEX BCF-FLEXROD DESIGN for Challenging Fluids

The SEEPEX BCF-FLEXROD DESIGN is a highly efficient progressive cavity pump specifically designed for handling difficult-to-pump fluids with high solids content, such as sludge and biosolids. The pump features a unique flexrod design that allows for optimal performance and reliability in challenging applications.

The BCF-FLEXROD DESIGN boasts several key features that set it apart from other pumps on the market. These include a large inlet that reduces the risk of clogging and allows for high flow rates, an adjustable stator that ensures consistent performance over time, and a proprietary sealing system that minimizes leaks and maintenance requirements.

In addition to its superior performance capabilities, the BCF-FLEXROD DESIGN is also easy to install and maintain. Its compact footprint and modular design make it ideal for both new installations and retrofits, while its low-maintenance design helps minimize downtime and reduce operating costs.

Overall, the SEEPEX BCF-FLEXROD DESIGN is an excellent choice for pumping challenging fluids in a variety of industries, including wastewater treatment, food and beverage processing, and mining and minerals processing.

Versatile Pump System for Industrial Applications: SEEPEX BCF-FLEXROD DESIGN

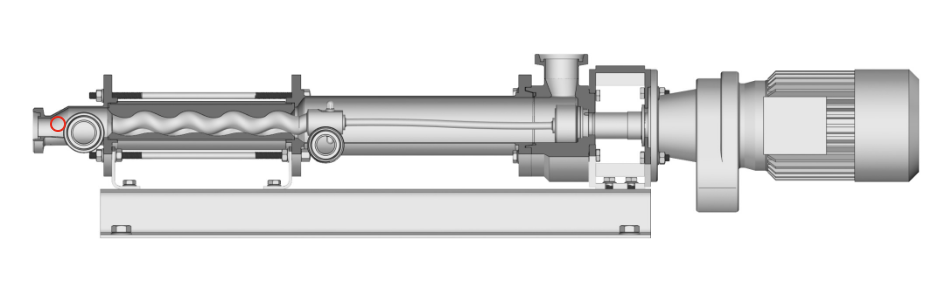

The SEEPEX BCF-FLEXROD DESIGN is a versatile pump system suitable for a wide range of applications. Its unique design consists of a flexible rod that transmits the rotary motion from the motor to the rotor, allowing it to handle highly viscous and abrasive materials with ease.

One common application of the BCF-FLEXROD DESIGN is in the food processing industry, where it is used to pump thick and chunky products such as fruit purees, sauces, and jams. The pump’s gentle handling of these delicate materials ensures that they are not damaged or broken down during the pumping process.

Another popular use for the BCF-FLEXROD DESIGN is in the wastewater treatment sector. Its ability to handle sludges and slurries with varying levels of solids content makes it ideal for use in both primary and secondary treatment processes.

In addition, the BCF-FLEXROD DESIGN is commonly employed in the chemical and petrochemical industries, where it is used to pump highly corrosive and hazardous substances such as acids, alkalis, and solvents. Its robust construction and ability to handle high pressures and temperatures make it a reliable choice for these demanding applications.

Overall, the SEEPEX BCF-FLEXROD DESIGN offers a versatile and efficient pumping solution for a wide range of industrial applications.

Fulfills strict hygienic standards

Certified under 3-A Sanitary Standards; the Flexrod additionally fulfills the highly demanding EHEDG requirements and utilizes FDA-approved components

Residue free cleaning

Thanks to special housing geometry, joint-free Flexrod and tangentially positioned flush connections: CIP, SIP, COP

Service-friendly

Low space requirements and no special tools required for maintenance – simply release the Flexrod from the rotor and drive shaft

Low pulsation

Minimal pulsation and low shear characteristics allow the transport of sensitive products – even containing whole pieces

Process-optimized

Low cleaning costs and reduced production facility downtime due to quick and simple maintenance

People Also Ask