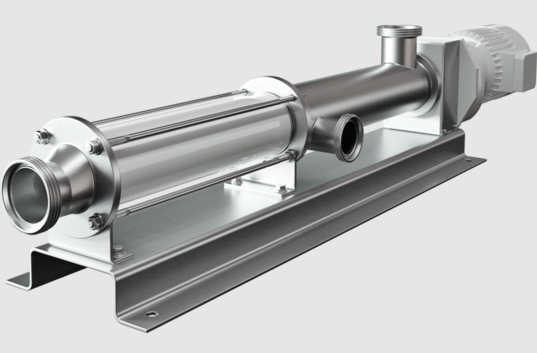

SEEPEX BCSO FOOD AND HYGIENIC PUMP

The hygiene-compliant design of the BCSO food and hygienic pump from SEEPEX is certified under 3-A Sanitary Standards. It can be cleaned without leaving any residues using CIP and SIP methods, and therefore fulfills the strictest requirements for hygienic cleanliness. Furthermore, the materials of the individual components are food-certified (FDA / EU 1935-2004). Thanks to the special design of the corrosion and wear-resistant joints, maintenance work can be performed quickly and without special tools.

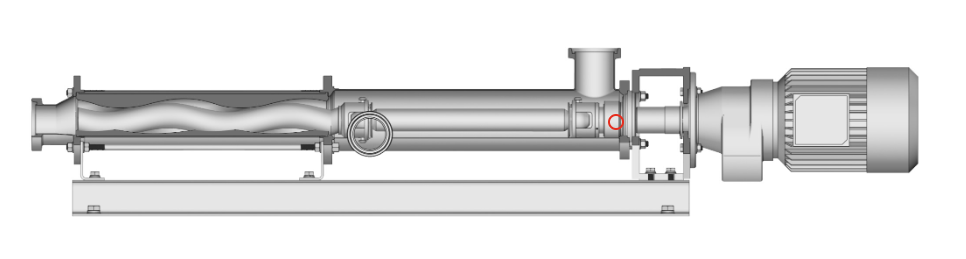

Durable and Maintenance-Friendly Mechanical Joints

The SEEPEX BCSO open pin joints are a type of mechanical joint used in the construction industry. These joints allow for movement and rotation between two connected components while maintaining their structural integrity. The open design of these pin joints allows for easy inspection and maintenance, making them a popular choice for applications where regular inspections are necessary. SEEPEX BCSO open pin joints are made with high-quality materials to ensure long-lasting durability and optimal performance.

Application of SEEPEX BCSO Open Pin Joints in Hygienic Progressive Cavity Pumps

SEEPEX BCSO Open Pin Joints are designed to be used in a variety of applications, including hygienic progressive cavity pumps. These joints provide easy access for maintenance and cleaning, ensuring maximum hygiene and minimal downtime.

When incorporated into the design of products such as the SEEPEX Progressive Cavity Pump, EHEDG food pump, and other hygienic pumps, these open pin joints facilitate fast, easy disassembly, and reassembly, reducing the amount of time required for maintenance and repair.

The use of SEEPEX BCSO Open Pin Joints in hygienic progressive cavity pumps ensures that these pumps meet stringent sanitary requirements necessary for food processing and other industries where hygiene is paramount. Additionally, these joints improve the efficiency and longevity of the pumps by minimizing wear and reducing the risk of contamination.

Fulfills strict hygienic standards

Certified under the 3-A Sanitary Standards and designed in compliance with the EHEDG guidelines, and fitted with FDA-approved and EU 1935-2004 compliant components

Service-friendly

Maintenance work without the need for special tools thanks to the open design of the joints, using only a few components

Low pulsation

Minimal pulsation and low shear characteristics allow the gentle conveyance of sensitive products – even containing whole pieces

Process-optimized

Low cleaning costs and reduced production facility downtime due to quick and simple maintenance

Residue free cleaning

Special housing geometry and open, hygienic pin joints facilitate optimal cleaning and sterilization: CIP, SIP, COP

People Also Ask