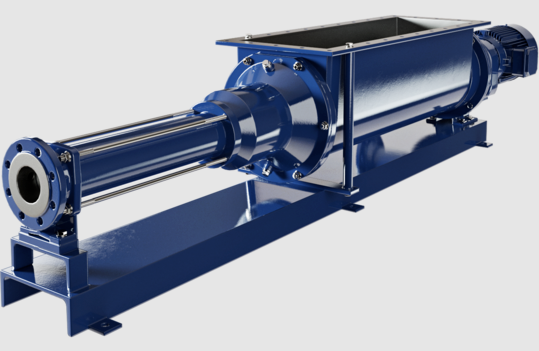

BTHE – WITH EDGE-TO-EDGE RIBBON SCREW

The BTHE hopper pump is characterized by vertical hopper walls and a large-diameter ribbon screw in the hopper. In contrast to the BTH, the ribbon screw and the rotating unit are controlled by only one drive unit. Thanks to the large screw diameter, even media that tend to bridge can be conveyed without any problems. The pump can optionally be equipped with Drive Joint Access.

Introducing SEEPEX BTHE with Edge-to-Edge Ribbon Screw

SEEPEX BTHE is a revolutionary pump technology that features an edge-to-edge ribbon screw, delivering exceptional performance and efficiency in handling highly viscous materials. The ribbon screw design ensures continuous flow with minimal pulsation, while the edge-to-edge configuration prevents material buildup and clogging. With its robust construction and high-quality components, the SEEPEX BTHE pump is engineered to handle the toughest applications in various industries such as chemical, food, and pharmaceutical.

The SEEPEX BTHE pump series provides unparalleled versatility and flexibility for process operators. It can be configured with different motor types, sealing options, and material combinations to meet specific process requirements. Additionally, its compact design allows for easy integration into existing systems or installation in tight spaces.

Overall, the SEEPEX pump with Edge-to-Edge Ribbon Screw represents a breakthrough in progressing cavity pump technology. Its innovative design and superior performance make it an ideal choice for operators seeking reliable and efficient pumping solutions for their most challenging applications.

Application of SEEPEX BTHE with Edge-to-Edge Ribbon Screw

The SEEPEX BTHE pump with Edge-to-Edge Ribbon Screw is a versatile and reliable solution for handling highly viscous and shear-sensitive materials in various industries. The pump’s unique design features a ribbon screw that runs the entire length of the stator, providing excellent axial stability and reduced pulsation.

One application where the SEEPEX BTHE with Edge-to-Edge Ribbon Screw excels is in the food industry, particularly in the production of sauces and dressings. These products often contain ingredients that are difficult to handle, such as chunks of vegetables or fruit, seeds, and spices. The SEEPEX BTHE can easily handle these challenging materials without damaging them or changing their consistency.

Another application is in the chemical industry, where the pump’s ability to handle shear-sensitive materials makes it an ideal choice for transferring products such as polymers, resins, and adhesives. The SEEPEX BTHE with Edge-to-Edge Ribbon Screw ensures gentle handling of these materials, preventing degradation and maintaining product quality.

In summary, the SEEPEX BTHE pump with Edge-to-Edge Ribbon Screw is a highly efficient and versatile solution for handling a wide range of materials in various industries. Its unique design provides superior performance and reliability, making it a popular choice for many applications.

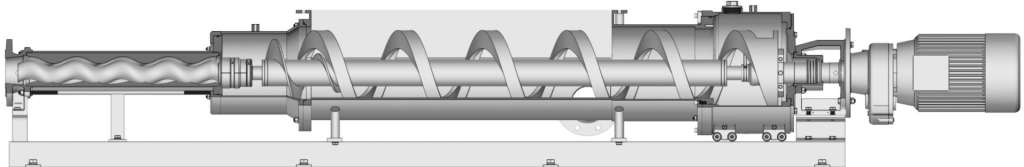

No bridging

Thanks to the centrally oriented, edge-to-edge ribbon screw with a large diameter and elongated pitch

Improved flowability

Thanks to the very large screw conveyor, even for products with little or no flowability

Optimum product conveyance

Conveyance of the optimal flow rate to the downstream rotating unit by compressing the medium in the compression zone

Easy maintenance

Simple dismantling of the compression casing for servicing work and optional Drive Joint Access for simple access to the drive-side joint

Variable

Available in block design with directly flanged-on drive system, or as a variant with free bare shaft and plug connection

People Also Ask