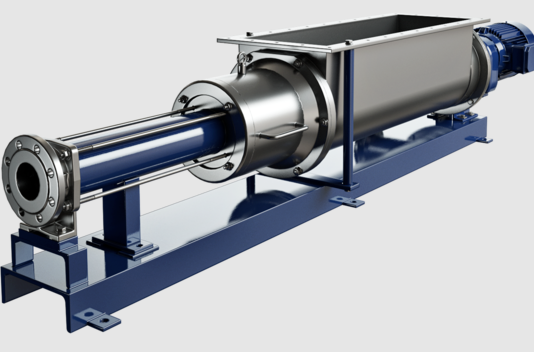

FROM HIGHLY VISCOUS TO SEMI-SOLID

BTVE hopper pumps from SEEPEX provide the ability to transport dewatered sludge with a dry matter content of up to 30%. A large, rectangular intake hopper with screw conveyor allows them to easily be fed with highly viscous and semi-solid products with no tendency towards bridging. A roller-mounted sliding compression casing further simplifies dismantling, thus allowing the cleaning and maintenance of the rotating unit.

High-Performance SEEPEX BTVE Pump with Robust Full Screw

The SEEPEX BTVE pump with robust full screw design is a high-performance industrial pump that delivers reliable and efficient performance in even the harshest operating conditions. Its unique full screw design provides superior suction capabilities, enabling it to handle difficult media with ease, while its sturdy construction ensures long-lasting durability. Available in various configurations, the SEEPEX BTVE pump can handle abrasive materials, high-viscosity liquids, and corrosive chemicals, making it a versatile and reliable choice for industrial processes.

Applications of the SEEPEX BTVE Pump with Robust Full Screw

The SEEPEX BTVE pump with robust full screw design is ideal for a range of industrial applications. It’s commonly used in the chemical, pharmaceutical, and food processing industries for transferring abrasive materials, high-viscosity liquids, and corrosive chemicals. This pump can handle challenging media with ease, making it suitable for use in applications such as wastewater treatment, pulp and paper manufacturing, and mining operations. Its superior suction capabilities and sturdy construction make it a reliable choice for demanding environments, ensuring optimal performance and efficiency. Overall, the SEEPEX BTVE pump with robust full screw design is a versatile and dependable solution for a wide range of industrial pumping needs.

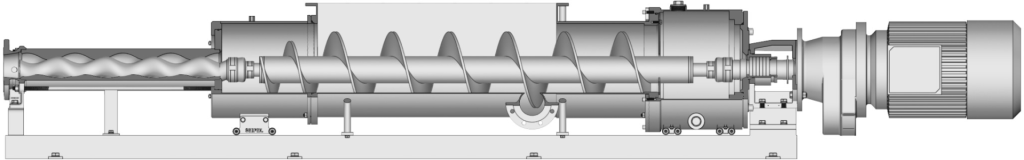

Easy maintenance

Simplified access to joint and rotor thanks to roller-mounted sliding compression casing

Easy to clean

Fast and powerful cleaning of all parts in the hopper via flange connections mounted directly on the intake hopper

Optimum product conveyance

Optimal conveyance of the product to the downstream rotating unit via a screw conveyor installed in the hopper with a large diameter and long pitch

Adaptable

Length of rectangular intake hopper adjustable to upstream components

Variable

Available in block design with directly flanged-on drive system, or as a variant with free bare shaft and plug connection

People Also Ask