REALLY WELL MIXED

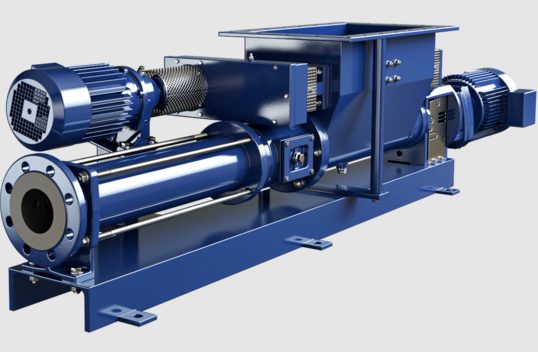

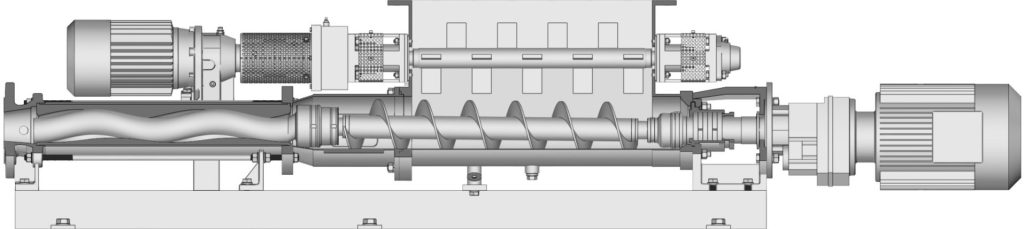

When media are inclined to bridging, smooth product delivery to the conveying elements cannot always be assured. The BTI hopper pumps from SEEPEX provides a solution. The rectangular hopper contains two counter-running paddle shafts equipped with their own drive system. These mix highly viscous media so thoroughly that bridging cannot even begin to take place – ensuring optimal delivery of the medium to the pump at all times.

Introduction to BTI with Integrated Bridge Breaker

- The SEEPEX BTI with Integrated Bridge Breaker is a cutting-edge circuit breaker technology that combines the features of a breaker and a bridge into a single unit. This innovative design helps to improve the safety and efficiency of power systems by providing quick and reliable protection against overloads and short circuits.

- The BTI Pump with Integrated Bridge Breaker boasts a compact and lightweight design, making it easy to install and maintain. It also comes equipped with advanced monitoring and diagnostic capabilities that allow for real-time status updates and fault detection, ensuring optimal performance and preventing downtime.

- This breakthrough technology is ideal for a wide range of applications, including residential, commercial, and industrial settings. Its unique combination of features makes it an excellent choice for anyone looking to enhance the reliability and safety of their power systems.

Applications of BTI – WITH INTEGRATED BRIDGE BREAKER

- Industrial machinery: BTI – WITH INTEGRATED BRIDGE BREAKER is commonly used in industrial machinery to protect against short circuits and overloads. It provides improved system reliability and simplified installation and wiring.

- Automation systems: BTI – WITH INTEGRATED BRIDGE BREAKER is suitable for automation systems that require a reliable and compact circuit breaker solution. Its bridge and circuit breaker functions combined in a single device make it a cost-effective option.

- Power distribution units: BTI – WITH INTEGRATED BRIDGE BREAKER is ideal for power distribution units that require high breaking capacity and protection against short circuits and overloads. Its compact size saves space and reduces installation time.

- Renewable energy systems: BTI – WITH INTEGRATED BRIDGE BREAKER is increasingly being used in renewable energy systems such as solar panels and wind turbines. It offers better protection and reliability compared to traditional circuit breakers, ensuring uninterrupted power supply even in harsh environments.

No bridging

Thanks to the bridge breaker consisting of two counter-rotating paddle shafts, which keep the medium in constant motion

Optimum product conveyance

Feed flow to the screw conveyor is guaranteed, even for highly viscous products, thanks to bridge breaker

Flexible control

Flexible adjustment of speed thanks to separate drive system for bridge breaker – irrespective of pump speed

Easy maintenance

Quick and simple maintenance thanks to the easy dismantling of the compression casing

People Also Ask